Hydraulic Oil Basics: Functions, Types, and Performance Factors

Engine Oil Types and How to Choose the Right One

Lubrication Explained: Types, Functions, and Examples

Oil Consolidation Reimagined: The 5S Method for Smarter Lubrication Practices

Gear Oil: Types, Applications, and Benefits

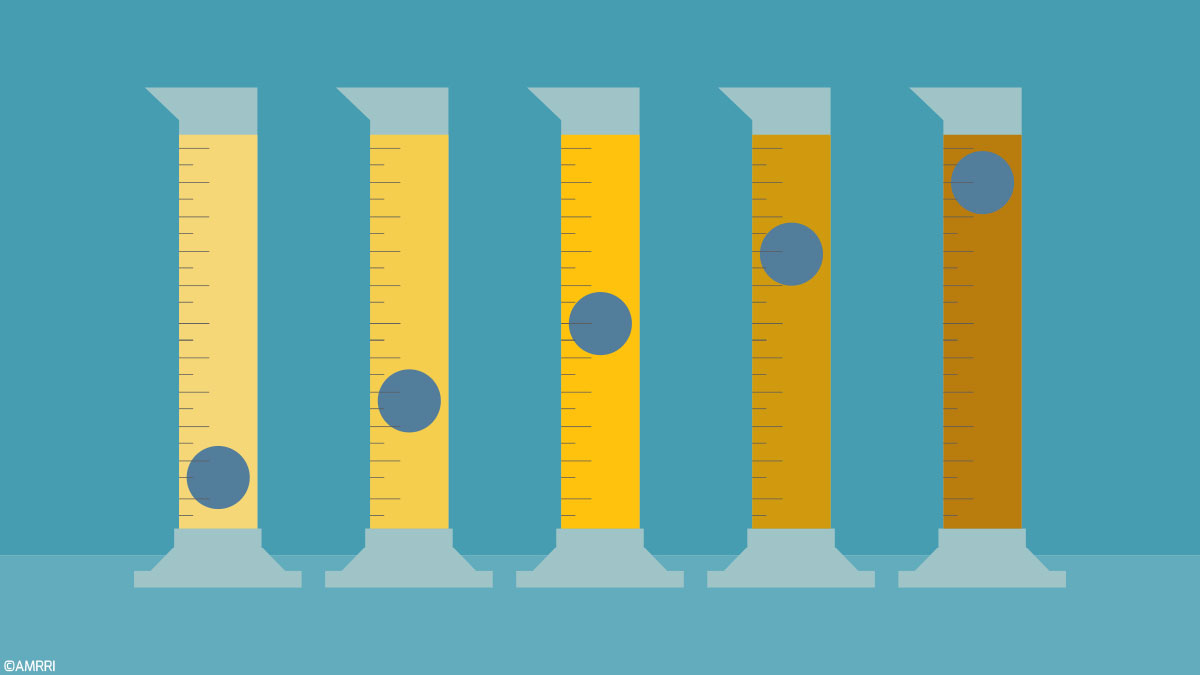

Viscosity Index Improvers Explained

Defoamants, Dispersants, and Detergents in Lubricants: A Complete Guide

Antioxidants In Lubricants: Essential or Excessive?

Lubricant Additives: A Comprehensive Guide

Antiwear Additives: Types, Mechanisms, and Applications

How Oil-Soluble Cleaners Can Redefine Lubricant Degradation Management

Microdieseling Causes, Effects and Detection

Here’s A More Comprehensive Approach to Revealing Oxidation Root Causes

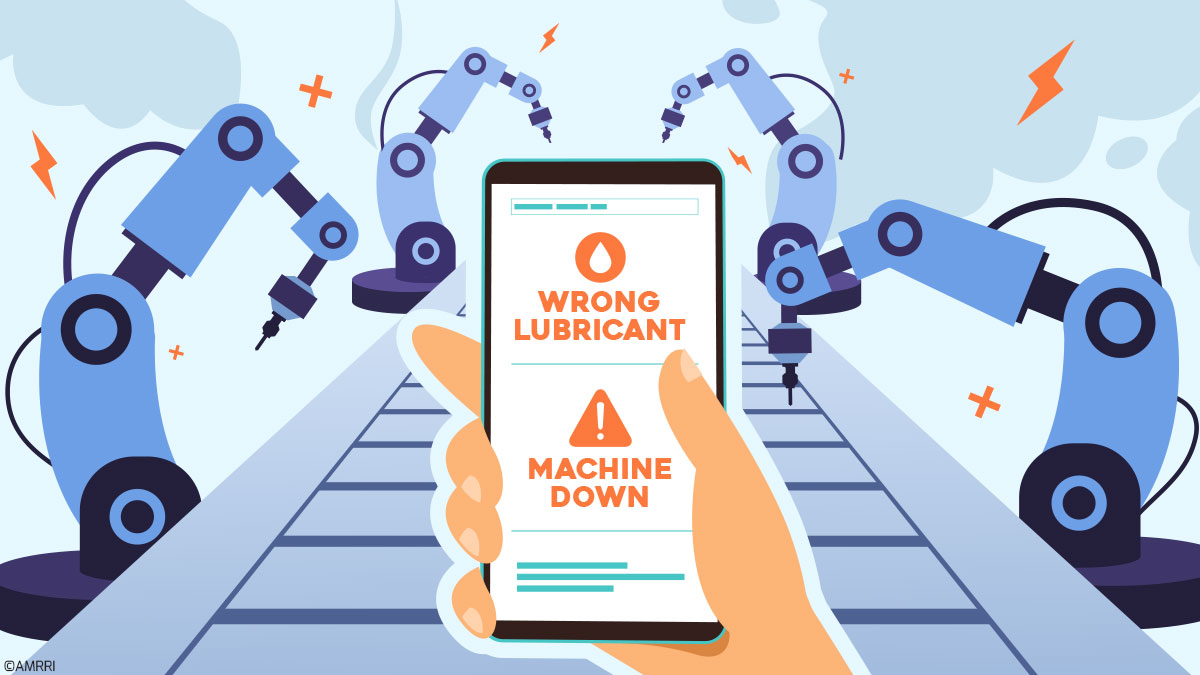

How Lubricant Selection Impacts Degradation and Machine Failure

Oil Viscosity: A Practical Guide

Energy Efficiency: The Critical Step Towards Sustainable Lubrication

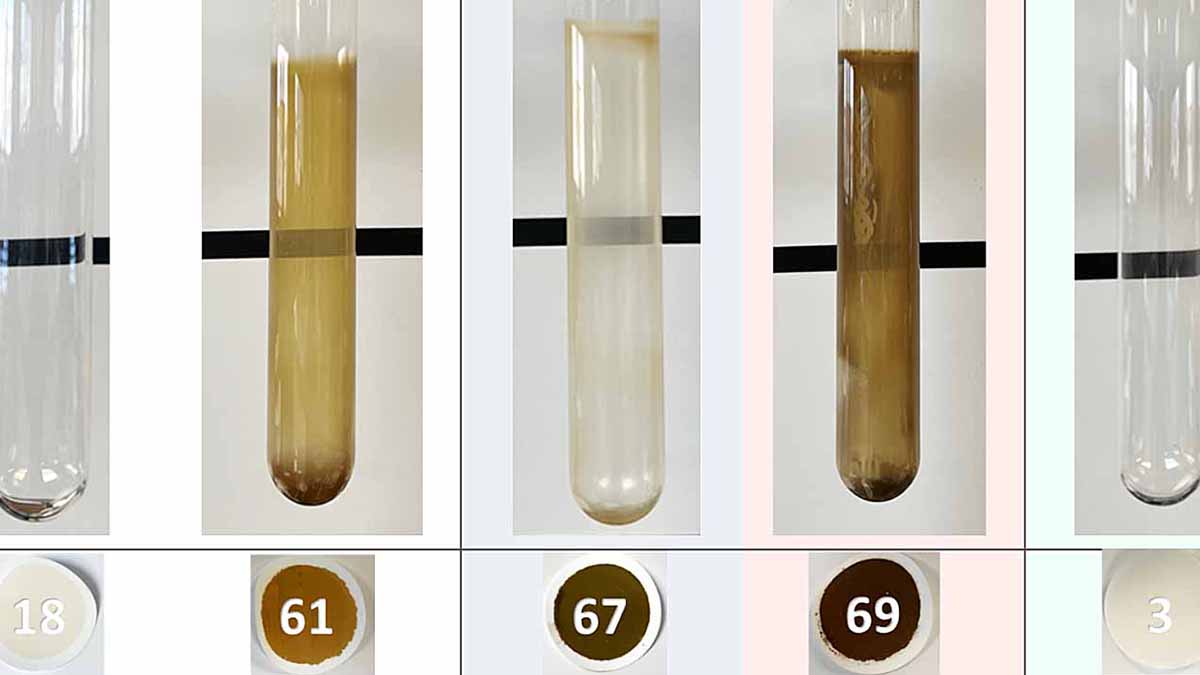

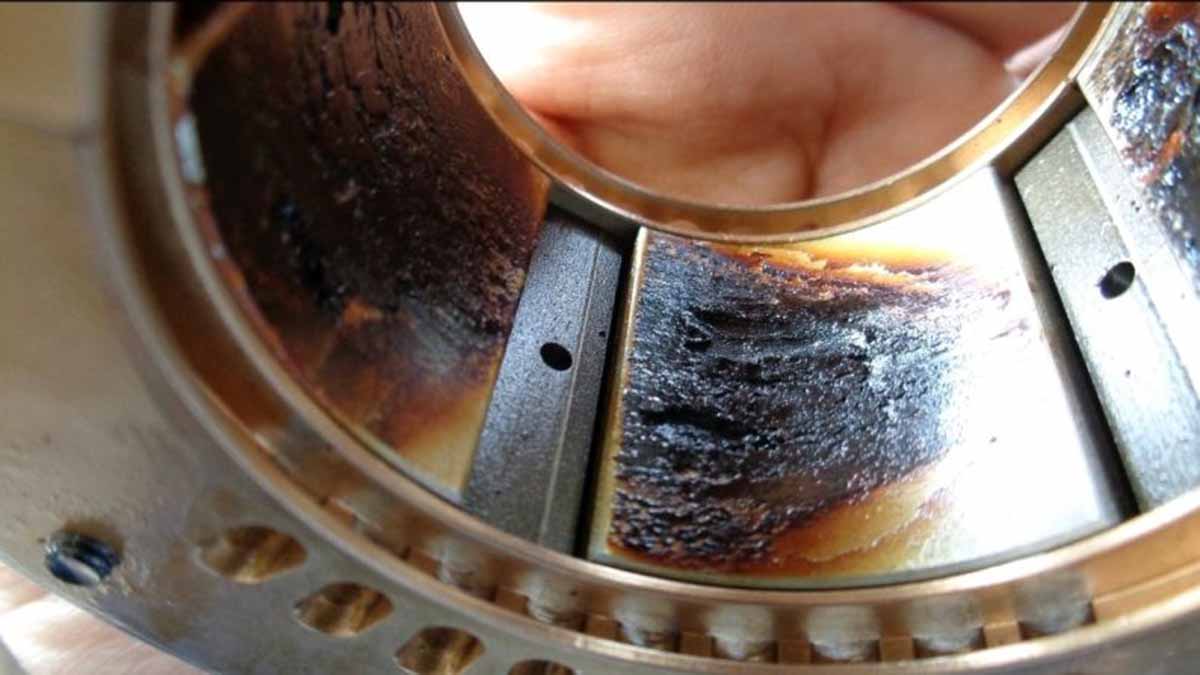

Lube Oil Varnish Detection and Control