Hydraulic systems are used to transmit force from one point to another via a fluid. This fluid is usually hydraulic oil, and the concept is based on Pascal’s law. Hydraulics are present in nearly all industries and play a critical role in enhancing operational...

Articles

How to Read Engine Oil Labels and Choose the Right Specification

This article provides a detailed overview of the classification of engine oils in the context of two key parameters that determine their operational suitability: viscosity properties and quality standards. Classification of Engine Oils The basic criterion for...

Why Air Breathers Are a Critical but Overlooked Contamination Barrier

Over the past two decades, while conducting numerous Lubrication Benchmark Assessment audits across a wide range of industries—from Oil and Gas, refineries, petrochemical plants, and power generation facilities, I have witnessed one of the most neglected areas of...

How to Set Oil Cleanliness Targets That Extend Gearbox Life

Solid Particle Cleanliness In my previous articles, I have discussed how to achieve cleanliness within gearboxes and pumps, examining the entire aspect of solid particulate contamination ingress. However, I was recently asked by an engineer following the above...

Extend Turbine Oil Life and Stability with Targeted Replenishment

In the high-stakes arena of power generation, turbine oil life has always dictated the tempo of reliability. A century of operating experience taught plant engineers one brutal truth: once an oil’s antioxidant package collapses, varnish doesn’t politely knock—it kicks...

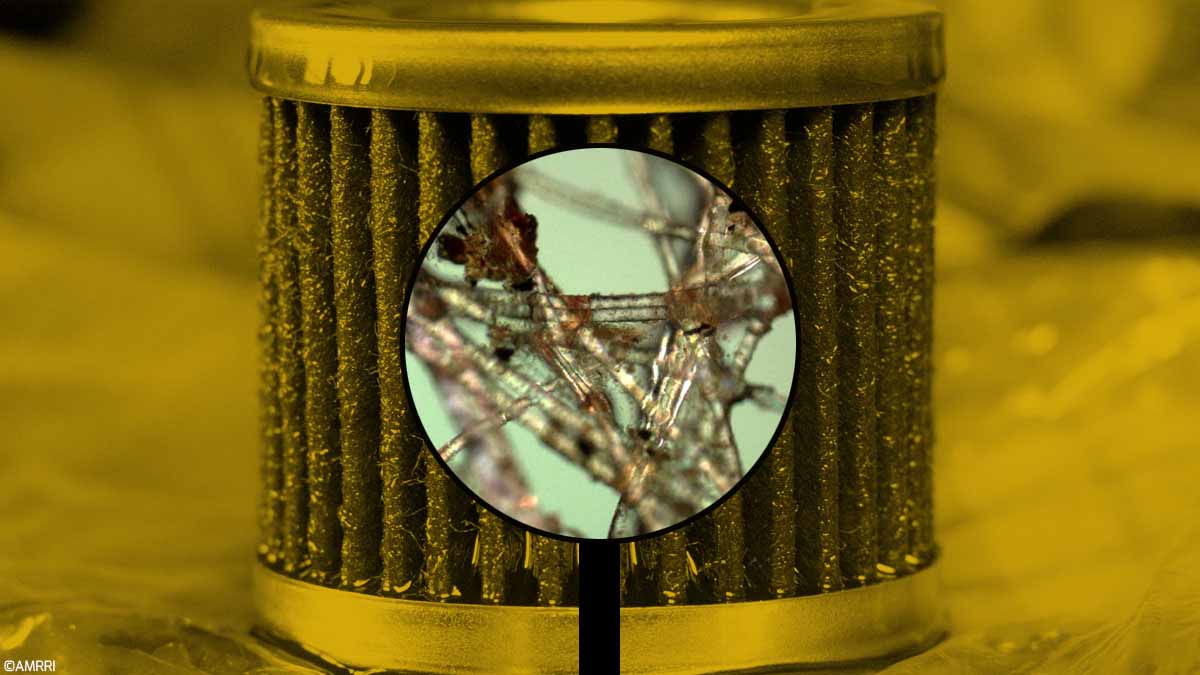

Why Oil Filter Analysis Should Be in Every Reliability Program

Condition monitoring tools such as vibration analysis, ultrasound, oil analysis, and thermography are mainstays of a condition-based maintenance strategy, each providing a unique perspective on the health of critical rotating and reciprocating assets. Vibration...

Ferrous Debris Measurement Methods That Improve Maintenance

Ferrous debris refers to small metallic particles, primarily iron, found in lubricating oils and greases caused by mechanical wear and damage to metal components. Early detection of this debris is critical, as it can indicate system wear before major damage has time...

How to Apply the Pareto Principle to Oil Analysis for Smarter Maintenance Gains

In industrial maintenance and reliability engineering, few concepts are as intuitively powerful as the Pareto Principle—also known as the 80/20 rule. Originating from Vilfredo Pareto's observations of wealth distribution, this principle has evolved into a universal...

Why Oxidation and Thermal Stress Degrade Lubricants in Unique Ways

Lubricating oils play a critical role in rotating machinery's efficient and safe operation. However, these fluids are exposed to various factors that can deteriorate their performance over time. Two of the most common degradation mechanisms are oxidation and thermal...

The Economics of Clean Oil: Why Prevention Beats Repair Every Time

When it comes to hydraulic systems, oil contamination is one of the most insidious and persistent enemies. It is estimated that about 80% of failures in these systems are directly related to fluid contamination. The issue goes beyond simply cleaning the oil; It...