The mention of lubricant varnish in an industrial setting frequently evokes concerns regarding unscheduled equipment shutdowns, reliability challenges, and consequent extended downtime. However, a facet that often remains overlooked is the concept of 'solubility.'...

Lubricants

Why Varnish May Plague Your Gearbox Really Soon

Gears are everywhere. These versatile machine elements are present in all industries and used in pumps and drives of all sizes as a reliable way to transfer power. Industrial gear oils are a vital component of that reliability, helping to maintain separation between...

Why Turbine Oil Replacement Should Be Based on Condition, Not Time

Let's dive into a big question: When should we change the turbine oil in power plants? This question came up when I talked to someone who works at a power plant. There are two ways to decide when to change the oil: old-school thinking versus new-school thinking. The...

Yes, Lubricants Have a Shelf Life Too. Here’s How to Extend It.

Most lubricant products include a "best before date" on the packaging and labeling materials. Provided as a "when to use by" guide, these dates are based on a manufacturer's projected shelf life of a product when stored as directed, per information on its packaging....

How Wind Turbine Gear Oils Have Evolved to Combat Micropitting Problems

Wind energy has become an increasingly important component of our energy grid as the world moves toward more sustainable power generation sources. Although harnessing wind power to do helpful work extends back to ancient times (think sail ships and windmills), stable...

The Lubricants Myth: Why You’re Not Saving Money by Buying the Cheap Stuff

I chose this topic this issue because the biggest bang for any organization is to get their lubricants right. With anywhere from 50% - 70% of your current downtime being caused by improper lubrication, there is only one way to spend your limited maintenance and...

How to Use Lubricant Technical Data Sheets for Better Lubrication

Industry professionals and lubrication practitioners know the crucial role of proper lubricant selection in ensuring equipment operation efficiency. To help in this process, Lubricant Technical Data Sheets (TDS) serve as an essential resource. Whether conducting a...

Why Diesel Engine Oil Compatibility Matters for Fleet Managers

It's exceedingly rare to find a fleet of vehicles with the same make, model, and year of manufacture. I have never personally observed a single instance in my career. Fleet managers will be all-too-familiar with the challenge of stocking spare parts for their fleet,...

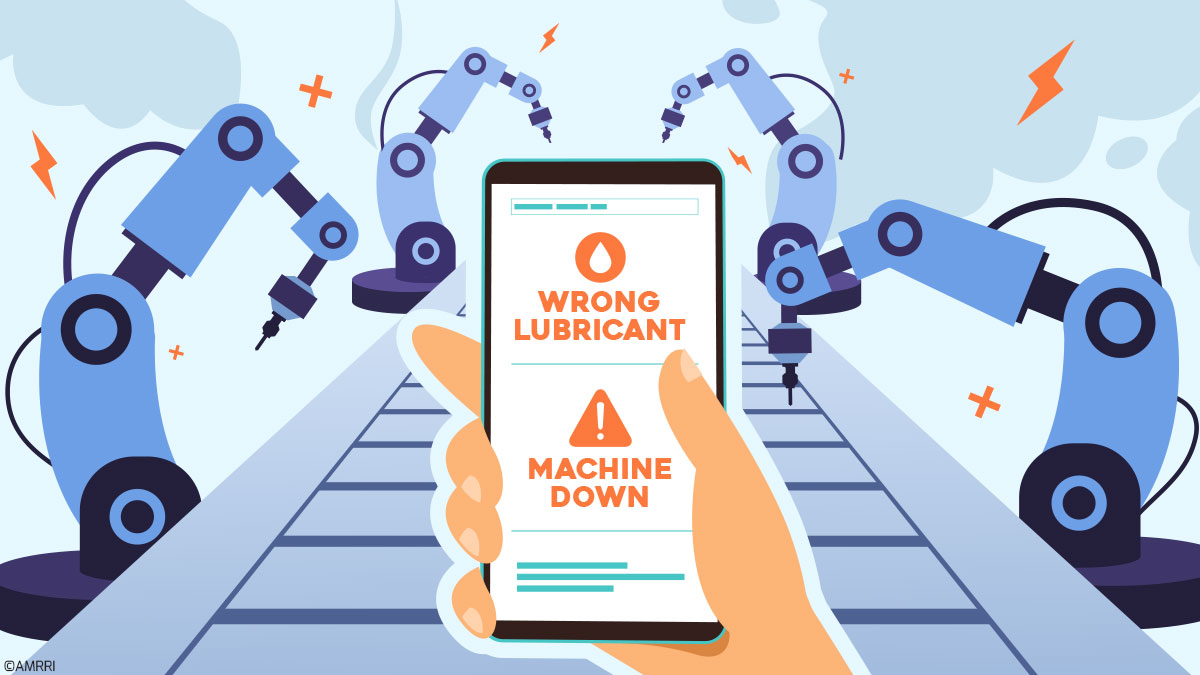

How Lubricant Selection Impacts Degradation and Machine Failure

Many lubrication engineers are faced with finding the most appropriate lubricant for an application. Therefore, they are tasked with selecting the "right" lubricant; subsequently, their decision can influence several outcomes. A lot of the positive results are in the...

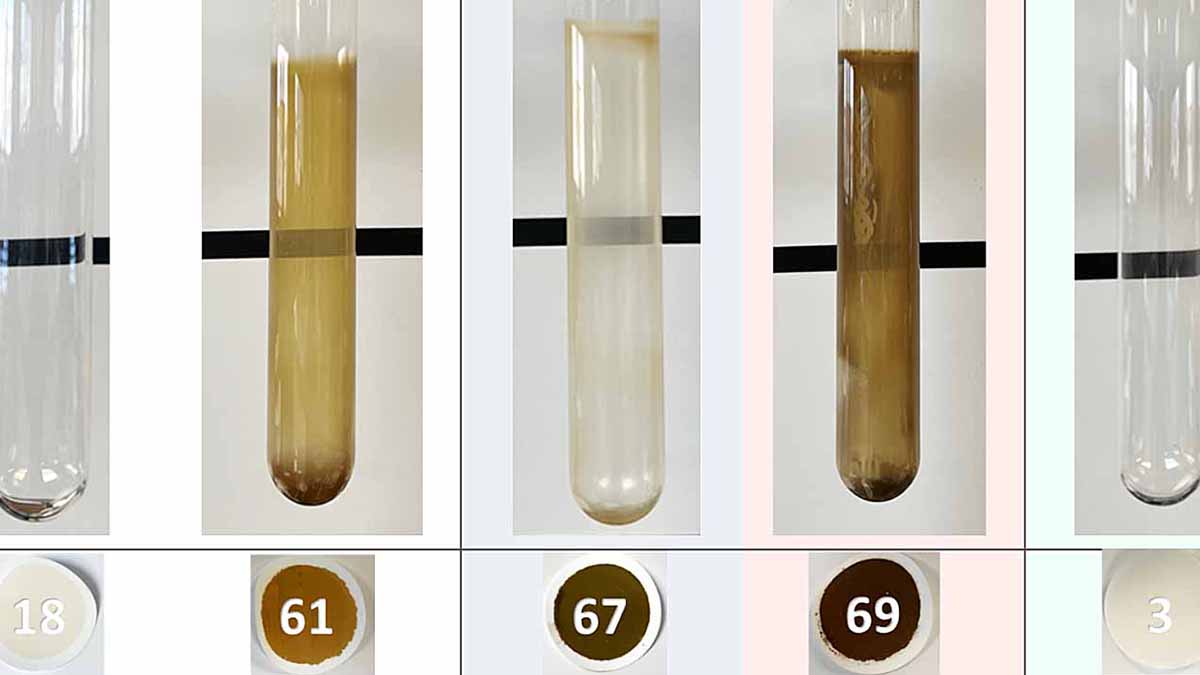

How to Select Turbine Oils Strategically for Improved Results Now

Turbine oils are required for some of the most complex pieces of turbomachinery equipment. Ideally, users should spend a great deal of time when selecting the right turbine oil, as an inappropriate selection could lead to significant undesired downtime. However, this...