Additives can enhance, suppress, or add new properties to oils. Defoamants, dispersants, and detergents are no exceptions. This trio of additives can be found in most finished lubricants, albeit in varying ratios. Let's discuss the main differences among these three,...

Lubricants

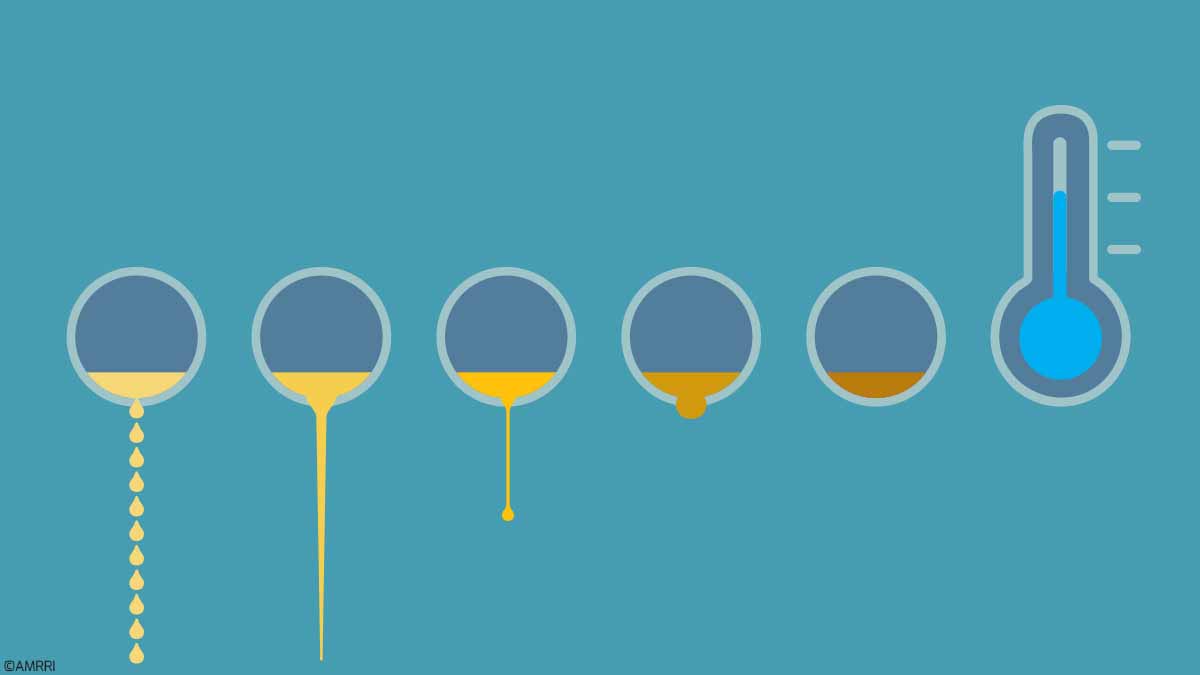

Pour Point Temperature and Testing: An In-Depth Guide

Pour Point Temperature – What Is It? The Pour Point Temperature is the temperature below which an oil loses its flow characteristics. It can be found in most Product Data Sheet (PDS) for an oil and in "Section 9: Physical and Chemical Properties" of the Safety Data...

Antioxidants In Lubricants: Essential or Excessive?

Antioxidants are additives that increase the oxidative resistance of the base oil to prolong lubricant life. They help prevent or reduce lubricant oxidation and work collaboratively with other additives in finished lubricants. Understanding Oxidation: The Basis for...

Revolutionizing Synthetic Lubricants: The Rise of New PAO Alternatives

Look at the product data sheet for any full synthetic industrial lubricating oil, and you will likely discover that the base oil is a polyalphaolefin (PAO). These lubricants have become the backbone of high-performance lubricants for the better part of 50 years, with...

Food Grade Lubricants: Categories, Compliance and Challenges

A lot has already been written about food grade lubricants, so a summary of what they are is a good place to start before taking a closer look at some of the issues relating to their use and the ongoing concerns in this area. Regulation of Food Grade Lubricants...

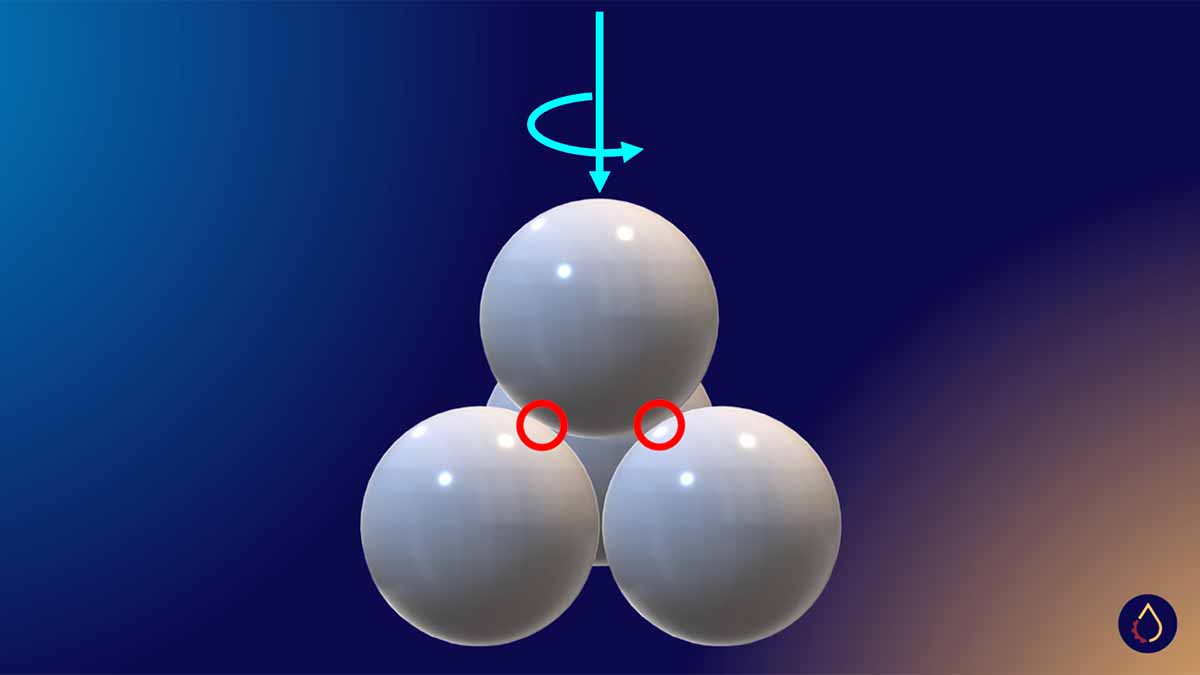

The Overrated 4-Ball Test: Why It Fails in Practical Lubricant Assessment

In the intricate world of lubrication and tribology, the 4-ball test has become a core experimental procedure and is commonly listed as a performance parameter on lubricant and grease data sheets. These tests are designed to measure friction and a lubricant's wear...

Lubricant Additives: A Comprehensive Guide

Lubricants keep the world turning. Once something moves, a lubricant should be present to reduce friction or wear between the surfaces. But what makes lubricants so unique in our industry? Is it just the base oil? No, this is where the power of lubricant additives...

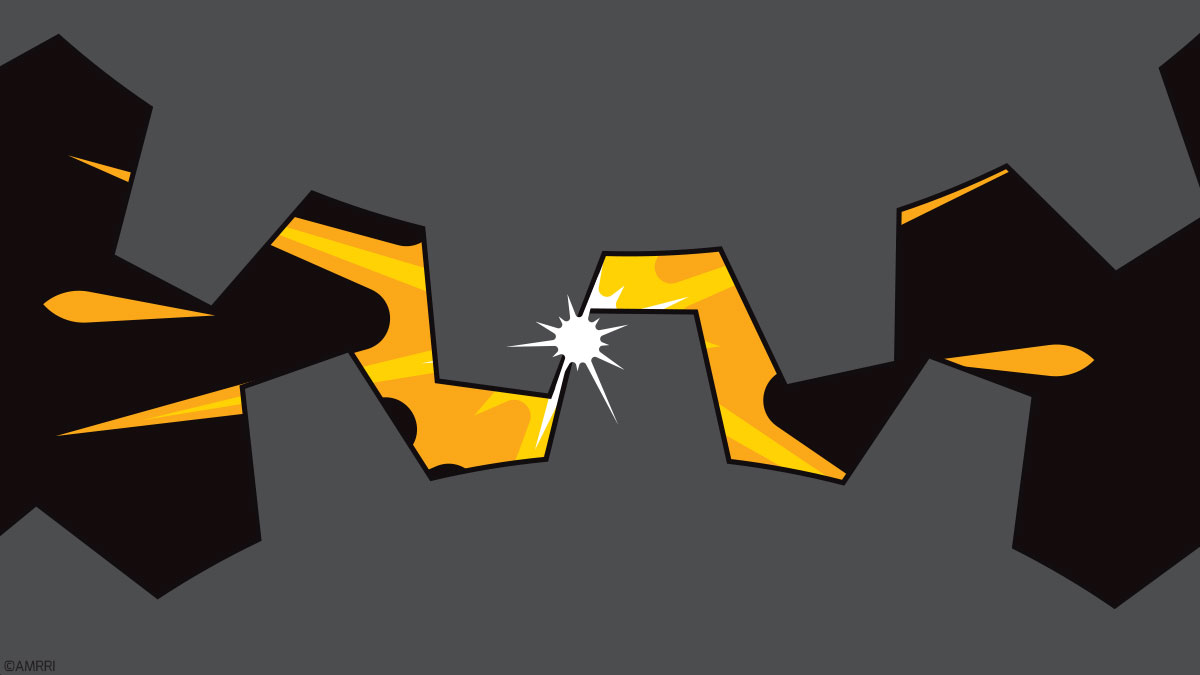

Antiwear Additives: Types, Mechanisms, and Applications

As the name suggests, antiwear additives help to prevent wear in one way or another. However, what makes them unique compared to other additives in lubricants? Why are they used more predominantly in specific applications than other applications? This article explores...

Strategic Lubricant Management for Non-Circulating Sump Systems

Lubricant management could mean different things to different people within a facility. The maintenance planner or lube crew supervisor may view lubricant management as the process that assures all the machines scheduled for level checks, replenishment, and oil...

RPVOT: Rethink Your Turbine Oil Replacement Strategy

In the world of industrial lubrication, the misconceptions surrounding RPVOT (Rotating Pressure Vessel Oxidation Test) have, unfortunately, cost companies millions of dollars. Imagine being faced with the daunting decision of prematurely replacing a substantial...