Industry professionals and lubrication practitioners know the crucial role of proper lubricant selection in ensuring equipment operation efficiency. To help in this process, Lubricant Technical Data Sheets (TDS) serve as an essential resource.

Whether conducting a lubricants consolidation study or performing a lubricant compliance check, TDS provide maintenance engineers with the information to make informed decisions regarding lubricant selection and maintenance.

What Is a Lubricant Technical Data Sheet?

A TDS is a one- or two-page document provided by lubricant blenders that contain technical information and performance details about the lubricant. TDS has other names, like Product Data Sheet or Product Information.

Understanding the content of a lubricant TDS can help accomplish the following objectives:

Proper Lubricant Selection

As detailed in the next section, Lubricant TDS clearly explains the lubricant’s physical and chemical characteristics and performance capabilities. This knowledge allows for a better alignment between lubricant properties and the desired equipment performance, such as improved corrosion protection, enhanced fuel efficiency, or high load-bearing and surface (extreme pressure) capability.

This enables users to make informed decisions to select lubricants of a certain quality level most suitable for their equipment and operating conditions. Furthermore, if applicable, TDS allows users to ensure that the lubricant meets recognized industry standards, requirements, and OEM approvals.

This knowledge minimizes the risk of using an unsuitable lubricant. Using the right lubricant reduces the risk of compatibility issues, mitigates potential warranty-related concerns, enhances equipment performance, and extends its useful life.

Equipment Health Condition Monitoring

The lubricant is a chemical product. Lubricant physical and chemical properties degrade over time, under the effect of operations and environmental conditions. The lubricant TDS can be used as a valuable troubleshooting tool by checking in-service lubricant condition against initial values included within its respective TDS.

Additionally, in case of lubrication-related issues or equipment failures, TDS can help identify potential causes by cross-referencing the lubricant’s properties and performance characteristics. This facilitates faster problem resolution, minimizing downtime and reducing associated costs.

Regulation and Industry-Specific Standards Compliance

Certain industries have specific regulatory requirements for lubricants. For example, lubricants must meet strict health and safety standards in Food Processing Industry. TDS helps to quickly check that lubricants comply with these regulations.

On the other hand, TDS may highlight any environmentally friendly features of the lubricant, such as biodegradability or eco-label certifications. This information is vital for applications where environmental compliance or sustainability is a priority.

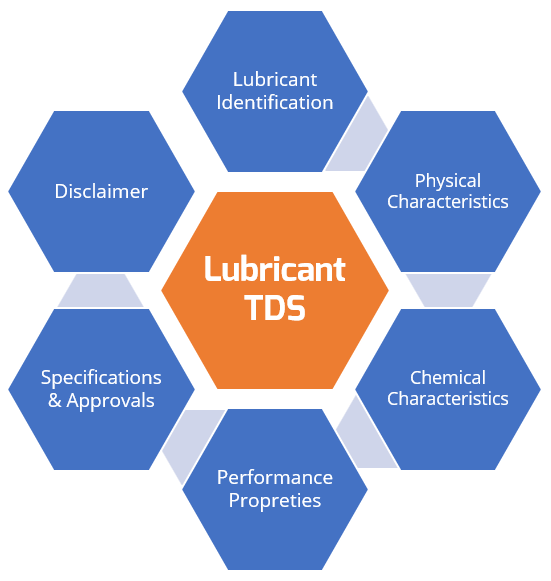

What Is on Lubricant Technical Data Sheets?

There is no standard for lubricant TDS, and they can typically be divided into various sections:

Generalities

Lubricant TDS typically begins with key elements for product identification, including its brand, name, and product code, if any. This allows easy identification and differentiation of a lubricant among various available lubricant options.

Additionally, this section of generalities includes a description of the product and some details about its blending formulation, including an overview of performance additives and the lubricant benefits.

The TDS also details specific applications where the product is intended to perform optimally: Equipment Type, Equipment Design, Operating Speeds, Temperature Ranges, and environmental factors—all this obviously with some cosmetics from marketing people.

Typical Lubricant Properties

Understanding the lubricant properties helps determine the lubricant’s suitability for specific applications and operating conditions. Accordingly, TDS includes laboratory measurements performed on the batch of product and provides crucial insights into the testing results of various physical and chemical parameters and performance tests.

- Physical Parameters: Lubricant TDS usually includes test results for a range of physical parameters that provide users with a comprehensive understanding of the lubricant’s physical properties. This information is needed to help determine the suitability of use for specific machine operating conditions. Some common physical parameters found in TDS include Viscosity measured at 40°C or 100°C, Viscosity Index and Density measured at 15°C or 20°C.

- Chemical Tests: Lubricant TDS typically includes many chemical test results or information that provides users with some insights into the performance characteristics of the lubricant. These chemical parameters help determine the lubricant’s stability and protective capability for common machine materials. Rust and Corrosion Protection and Oxidation Stability are chemical test performance data examples.

- Performance Tests: Lubricant TDS sometimes includes information about various performance parameters. These parameters highlight the lubricant’s ability to meet specific performance requirements and give users insights into its effectiveness in different applications. Under the umbrella of performance tests, we may find Load-Carrying Capacity, Friction Characteristics, and Wear Protection test data.

Example of how lubricant properties are provided within a lubricant TDS:

We cannot conclude this discussion on lubricant characteristics without highlighting that the specific performance parameters and their respective test results in the lubricant TDS may vary depending on the lubricant type, application, and manufacturer.

Further, where these standardized test results are lacking, it is reasonable to ask the lubricant vendor to provide these critical data points from unpublished internal resources.

Lastly, multiple petroleum performance test labs can be hired to supply or verify test result claims found on the TDS. Individual performance testing is typically not expansive.

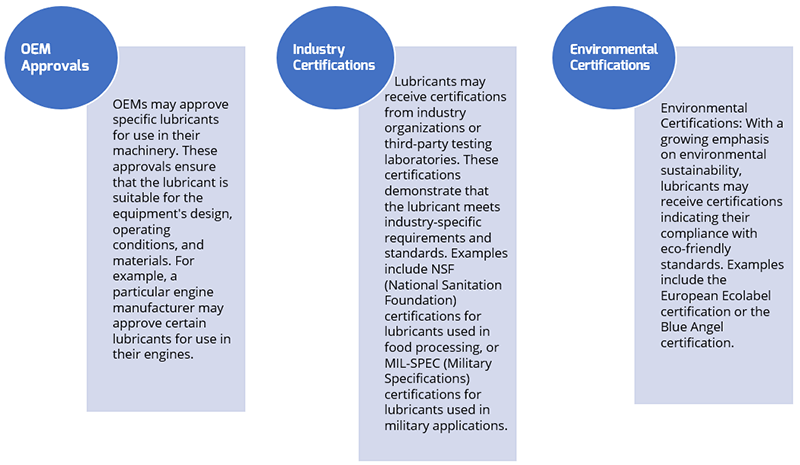

Specifications and Approvals

Specifications and Approvals are critical in ensuring that the lubricant meets the required quality and performance standards, thereby supporting optimal equipment performance. In some Lubricant TDS, specifications and approvals are merged in one section.

In these sections, Lubricant TDS outlines the performance specifications and industry standards that the lubricant complies with. Approvals from OEMs and industry certifications further assure that the lubricant is specifically formulated and has undergone rigorous testing.

It meets specific performance criteria to ensure the machinery’s performance capability and adherence to specific requirements. These specifications and approvals can be set by various organizations, such as international standards bodies or industry associations, including:

Lubricant Specification Sources

Disclaimer

In a separate section or included within every other section, disclaimers and warnings are considered important content provided by lubricant blenders about their product. It addresses restrictions and limitations and asserts that the provided information is based on the manufacturer’s current knowledge and experience.

It highlights that users should conduct their own assessments and tests to determine the lubricant’s suitability for their specific application(s). The disclaimer may also indicate that the manufacturer is not liable for any damages or losses resulting from using the lubricant based on the information provided in the TDS.

What Are the Limitations of a Lubricant Technical Data Sheet?

While Lubricant TDS provides valuable information about lubricants, it is essential to be aware of their limitations. Understanding these limitations helps users make informed decisions and ensures that TDS are used as a helpful tool rather than a sole determinant. Here are some lubricant TDS limitations to consider:

Generalized Information Vs. Required Customization and Specification

The information contained within a lubricant TDS is general. It may not address every specific requirement or operating condition. Users are urged to conduct additional laboratory tests to verify the lubricant’s suitability to their particular lubrication context. They should consult lubrication experts or refer to the lubricant supplier’s technical support for specific application guidance.

Lubricant Quality Control Vs. Long-Term Performance

Lubricant TDS provides information based on blending plant laboratory tests within the quality control process. It may not provide comprehensive data on the lubricant’s long-term performance or aging characteristics.

This way, Lubricant TDS focus on the lubricant itself and may not address external factors that can influence performance, such as equipment maintenance practices, contamination levels, or operating conditions.

Users should consider external factors, conduct additional tests or refer to experts and benchmarks to gather more insights about the lubricant’s performance within the operating context.

Legal Disclaimers

Lubricant TDS typically includes legal disclaimers that limit the liability of the lubricant manufacturer for any damages or losses resulting from using the lubricant. Users should be aware of these disclaimers and understand they assume responsibility for applying, using, and testing the lubricant in their specific circumstances.

In conclusion, lubricant TDS are part of a comprehensive lubrication strategy. This article aims to share guidelines to navigate the information presented within a lubricant TDS and gain insights into the critical aspects of lubricant selection and maintenance.

By understanding the significance of each section and its implications on lubricant performance, lubrication professionals can make well-informed decisions that align with their specific lubrication requirements. Thus, they will be empowered to optimize equipment performance and extend their useful life. One rule of thumb is to consider Technical TDS limitations as well.

Conducting additional tests, seeking guidance from lubrication experts, and considering application-specific factors are essential for ensuring optimal lubricant selection and maintenance.