At an industrial level, bearings are, without a doubt, the most widely used assets in all sectors and allow a lot of critical and non-critical equipment to remain in service. Depending on the source consulted, the first wooden bearings that were discovered date back...

Bearings

Unleashing the Power of Wireless Autonomous Bearing Monitoring and Lubrication

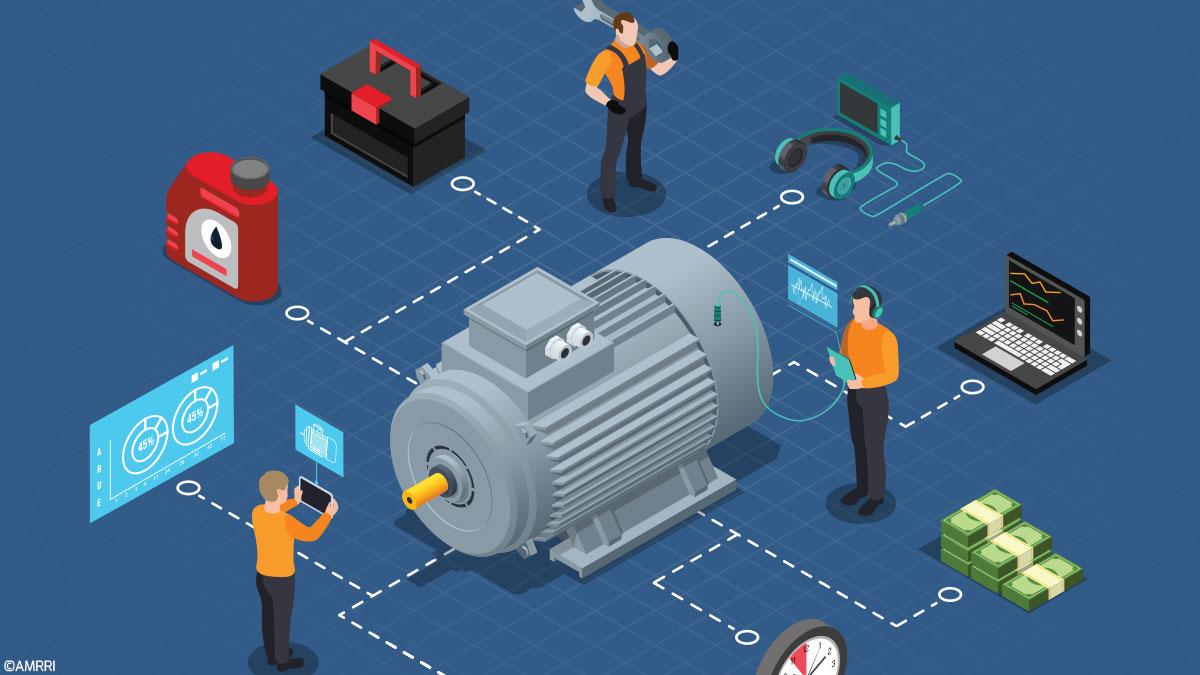

This presentation was presented at the Lubrication Reliability Virtual Summit on September 20, 2023 by Blair Fraser, with UE Systems. Discover how UE Systems cutting-edge technologies are revolutionizing maintenance practices, enhancing equipment performance and...

How to Extend the Life of Your Bearings with Effective Lubrication

There are few definitive studies on rolling-element bearing reliability /life based on industry uses and working conditions. However, many claims indicate that most such bearings never achieve their engineered-life rating (some going as low as 10%). Most in the...

How Contamination Impacts Rolling Element Bearing Life

In Parts 1 and 2 of this series, we discussed the evolution of rolling element-bearing life calculations from the original work of Lundberg and Palmgren in the 1940s and 50s to the most recent ISO 281 standard, published in 2007. In particular, we talked about the...

How to Properly Lubricate a Rolling Element Bearing

In Part 1 of this series we talked about the evolution of rolling element bearing life calculations from the original work of Lundberg and Palmgren in the 1940s and 50's to the most recent ISO 281 standard, published in 2007. Central to the ISO 281:2007 standard is...

The Fine Line Between Success and Failure in Condition-Based Greasing

Condition-based greasing is an old and desirable idea. It is the finesse approach to fulfilling grease-based bearing care when done with precision. Efficient. Effective. Reliability-Enhancing. The most desirable objective for grease-lubricated bearings. It can be...

How Long Should a Bearing Last?

The Evolution of Bearing Life Calculations and the ISO 281 Standard From slow-turning pillow block bearings to high-speed fan and electric motor bearings, rolling element bearings are the most common lubricated component in any industrial plant. The earliest known...

How Grease Analysis Helped Expose a Hidden Plant

Those who have worked in or around maintenance and reliability have probably heard about the hidden plant. This term refers to that portion of the productivity of any industry that, for some reason, is wasted and goes completely unnoticed in the eyes of the...

How Does the Bearing Bore Size Impact Grease Selection?

We often get questions during our training courses about lubricant selection. I was recently asked how bearing bore size impact grease selection. Let’s start with defining the type of bearing. There are element bearings that come with a variety of element shapes,...

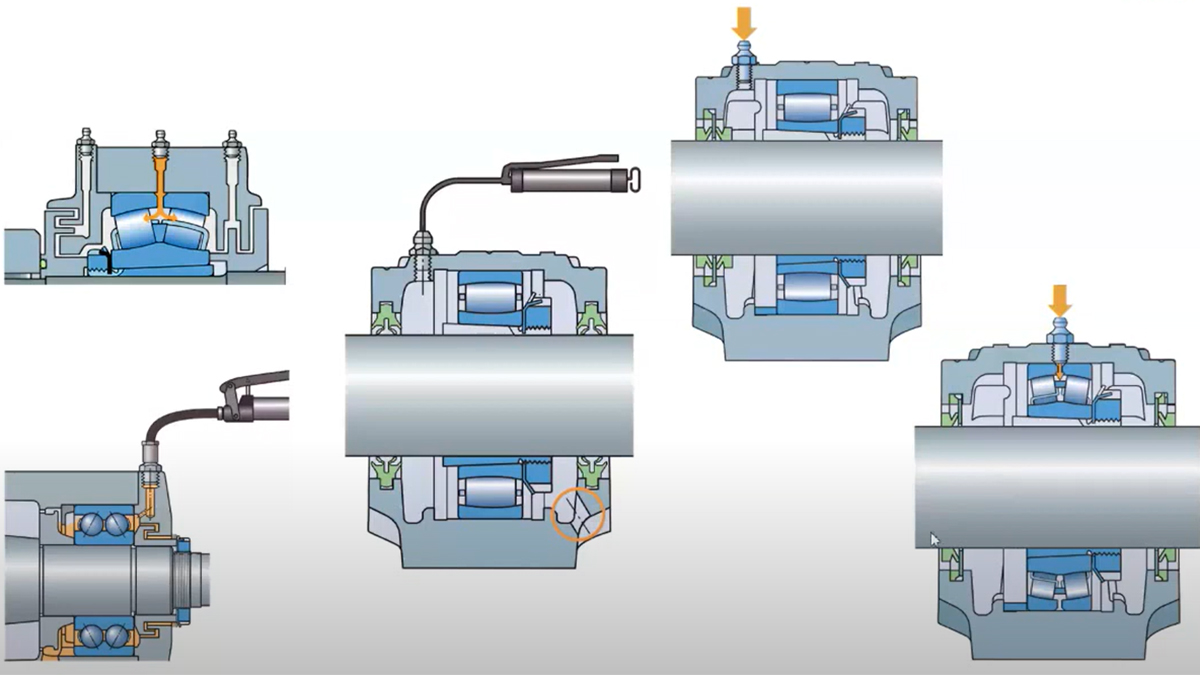

Bearing Lubrication: Boost Bearing Useful Life by Mastering Lubrication Management

Bearing failures can torment even the best maintenance professional, often resulting in expensive downtime and safety issues. By focusing on bearing lubrication and learning proper lubrication management skills, bearing failures can be prevented. In this video by SKF,...