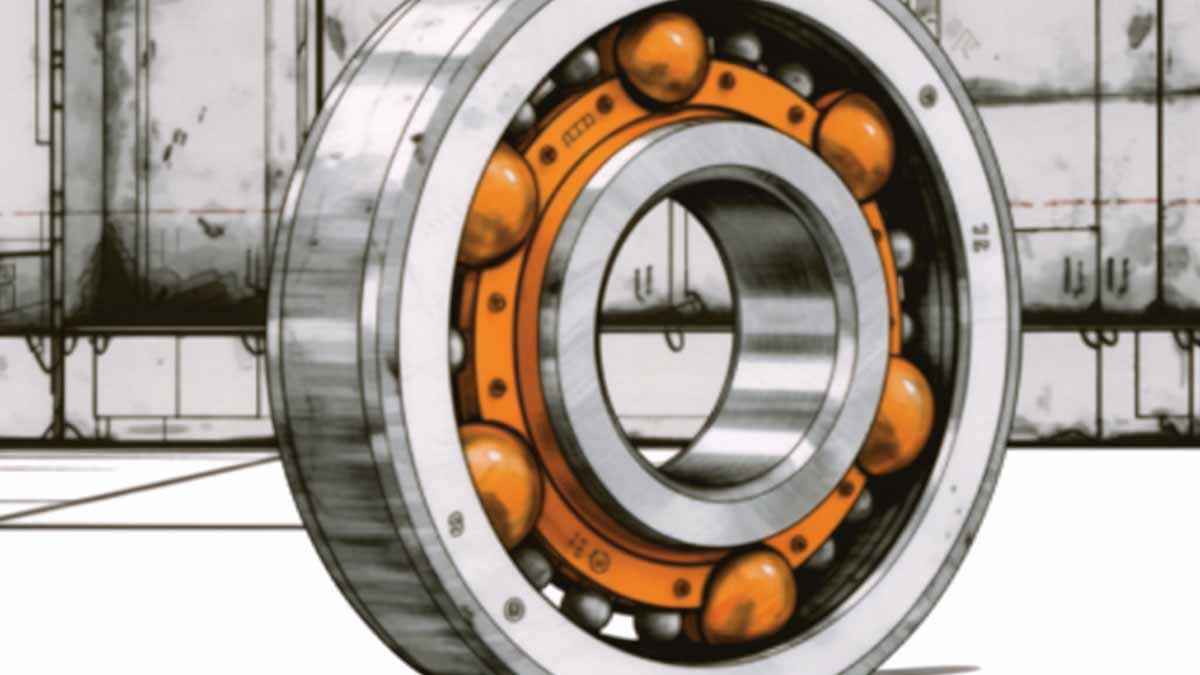

There are few definitive studies on rolling-element bearing reliability /life based on industry uses and working conditions. However, many claims indicate that most such bearings never achieve their engineered-life rating (some going as low as 10%). Most in the maintenance profession agree with this claim.

Recognizing that many rolling-element bearings lead a less-than-ideal life, often subjected to the severest conditions and abuse within industrial-plant environments, it’s important to note that there is a path to reliability through effective lubrication.

Understand Effective Lubrication

Maintainers know that bearings are designed and maintained to perform per their actual operating and environmental conditions, i.e., load, speed, temperature, and running time.

They also know that machinery design is often a compromise, with manufacturers making little or no adjustments in their design or recommended maintenance schedules for the end user’s unique ambient condition factors.

For example, a bearing can be used in a HEPA-filtered clean room manufacturing environment-running eight hours per day, set up using a laser-aligned and balanced shaft, and connected to an engineered automatic lubrication-delivery system.

That same bearing could also be placed in service in a hot, humid, and dirty 24-hour operation foundry, set up using a manual “eyeball” alignment, and manually lubricated with a grease gun on an “ad-hoc” basis. In this tale of two bearings, it isn’t difficult to determine—with a high degree of certainty—which bearing is most likely to achieve its engineered life rating.

In both scenarios, the assistance offered by the bearing manufacturer is very generic, as in, “Follow recommended bearing handling and storage recommendations; ensure the bearing is aligned correctly; and lubricate the bearing as necessary with a suitable lubricant.” The customer may or may not receive lubricant samples to use.

Suppose rolling-element bearings are to achieve their engineered life expectancy. In that case, maintenance departments must implement a lubrication management program designed to address and combat significant root causes of rolling-element bearing failure that include incorrect lubricant, lubricant contamination, over-lubrication (heat), and under-lubrication (starvation). The following details are crucial. It’s impossible to over-emphasize the damage to bearings from these four root causes.

Root Cause #1: Incorrect Lubricant

Selecting the correct lubricant for any application is essential. Lubricants provide liquid engineering by functioning on many different levels and are expected to:

- Reduce friction and wear by introducing a lubricant film of sufficient strength and thickness (viscosity) to support the load and separate the balls from the raceways, preventing any metal-to-metal contact;

- Minimize ball and roller-cage wear by using suitable lubricant additive packages to reduce the sliding friction in cage pockets and land surfaces. For example, anti-wear additive packages formulated in the lubricant;

- Provide a protective coating to prevent oxidation and corrosion of the bearing-rolling elements. For example, anti-corrosion, anti-foam, and anti-oxidation additive packages formulated in the lubricant;

- Act as a fluid barrier seal against outside contaminants; and

- Serve as a heat-transfer agent (re-circulative oil lubrication systems) to cool and conduct heat away from the bearing.

Selection of a suitable bearing lubricant will require decisions governed by the operating load and condition factors under which the bearing operates. The choice to use oil or grease will likely already have been determined by the design but choosing the correct lubricant will nearly always require assistance from a reputable lubricant manufacturer/supplier who can perform an engineered lubricant-consolidation program to decide on a minimized “suite” of suitable lubricants for your working environment.

Root Cause #2: Lubricant Contamination

Contamination is a considerable bearing killer, the most prevalent assassins being simple dirt and water!

Contamination avoidance is achievable through dedicated transfer and clean filtration equipment on transfer equipment and re-circulative lubrication systems. Good housekeeping is essential to keep reservoirs clean, greasing points clean, fill caps in place, breathers in place, and working.

Bulk fluids should be tested and analyzed to determine their fluid cleanliness and additive package formulation before use to confirm that they’ve been delivered to specification.

This is especially important in large-reservoir oil systems that lubricate many bearings simultaneously. Oils and grease should be kept from the elements to avoid water and rust entering the barrel top bung.

Root Causes #3 and #4: Over/Under Lubrication

Excessive heat is a common problem in manually greased bearings that have received too much grease. Virtually no two grease guns are alike in their lubricant displacement. A single shot in one grease gun could amount to five or more shots in a different-style gun.

Yet, a PM task may ask for two shots of grease, which results in over-greasing. Furthermore, a good-hearted maintainer may contribute to the problem by adding an extra “shot or two” in the mistaken belief that more grease is better.

Bearing cavities are designed to operate with a grease charge of approximately 40%. Thus, filling the cavity until the grease passes by the seal is more than two times the required amount.

Excess grease causes internal fluid friction in the bearing. In turn, this creates a significant rise in bearing temperature, resulting in reduced bearing life and a more substantial increase in energy use.

Ensure all grease guns in the plant deliver the same amount of grease displacement. Also, look into training to determine bearing requirements and how to effectively operate a grease gun.

Empty autolube reservoirs and disregarding manual lube tasks starve bearings to death. The reasons are many, including, among other things, simple neglect, incorrect lubrication intervals, and failed lubrication-delivery devices and equipment.

Bearings must be monitored when setting up the initial lube program to ensure lubricant intervals aren’t too frequent (which can result in over-lubrication) and not too infrequent (which can result in under-lubrication).

Bottom Line

Effective lubrication starts with a commitment to review your site’s current lube practices and develop a suitable lubrication management program. Most maintenance organizations already have the infrastructure and system to be organized and managed. The results can be astounding, and the cost is minimal.

This article was originally published in The Ram Review.