In Parts 1 and 2 of this series, we discussed the evolution of rolling element-bearing life calculations from the original work of Lundberg and Palmgren in the 1940s and 50s to the most recent ISO 281 standard, published in 2007. In particular, we talked about the role that Kappa – defined as the ratio of the actual viscosity of our lubricant to the minimum required to create separation of moving surfaces – plays in bearing life, as well as how optimizing regrease quantities and intervals are critical to optimizing bearing life.

But the release of ISO281:2007 also took our understanding of the factors that affect bearing life to a whole new level with the realization that we not only need the correct viscosity of lubricant to maximize bearing life, but the lubricant also needs to be clean!

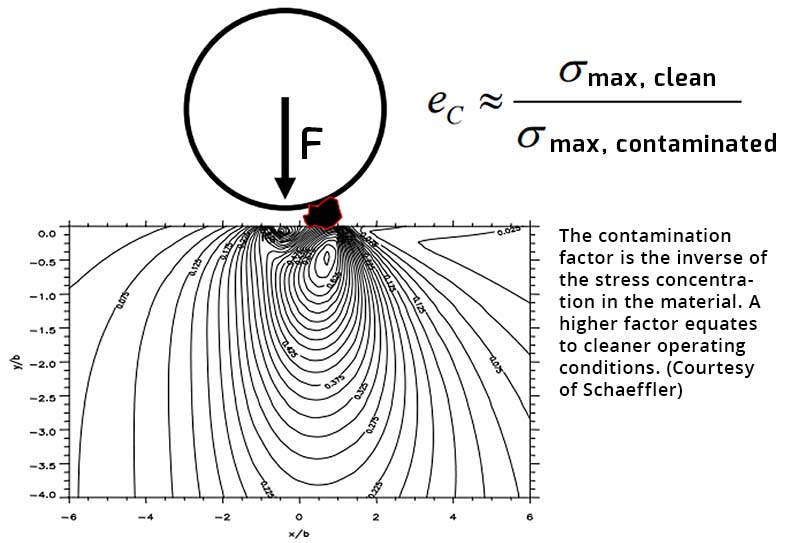

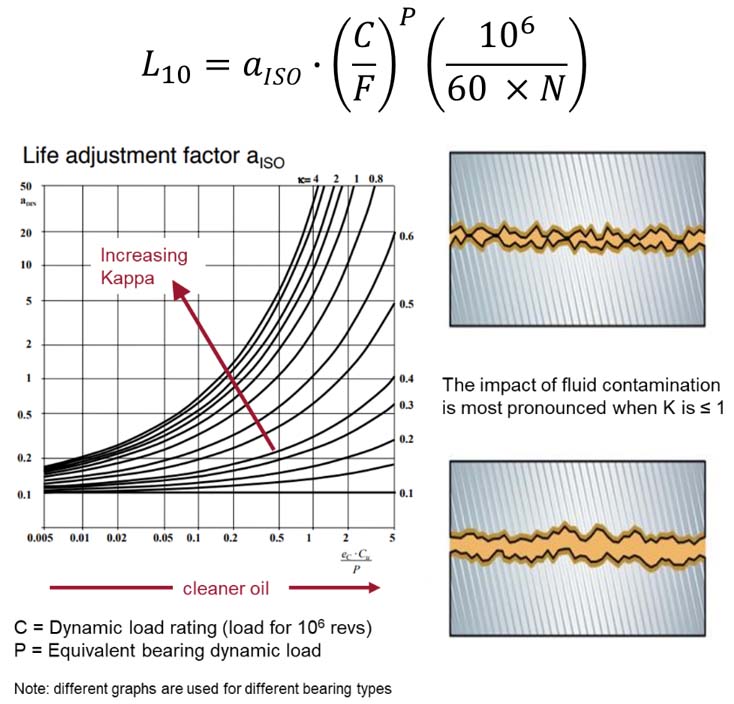

The 2007 version of the standard introduced a new term, ec, defined as the ratio of the inverse of the Hertzian stress concentration caused by the load across the rolling contact when the oil is clean, compared to the stress that is focused and localized by the presence of a dynamic clearance sized particle in the rolling contact (Figure 1).

Figure 1: Contamination factor, included in ISO281

Imagine two people walking across a hardwood floor to grasp this concept fully. Both have the same mass (weight), but if one is wearing high-heeled shoes while the other is wearing flat-soled shoes, the force generated by the localization across a small stiletto heal will create far greater stress and potentially damage the floor.

The same holds in element bearings: small particles the same size as the bearing dynamic clearances make an increased force that induces sub-surface stress in the bearing, ultimately leading to fatigue failure.

Aside from recognizing that particles can profoundly impact bearing life, it was also realized that cleanliness and Kappa go hand-in-hand. Metal-on-metal contact is inevitable when Kappa is very small (<1.0). As such, no amount of fluid cleanliness can change the fundamental physics that wear will occur!

Conversely, when Kappa approaches its optimum value of 4.0 (i.e., the operating viscosity of our lubricant is four times the minimum requirement), increased stress caused by the presence of dynamic clearance-sized particles can still have a significant impact on bearing life. Conversely, getting the oil cleaner can dramatically increase bearing life.

These two factors are represented in the ISO281:2007 standard by a combined terms aISO which is applied as a scalar to the original load-based factor from the original standard (Figure 2).

Figure 2: Bearing life adjustment factor aISO assuming a1=1.0 (i.e. L10 bearing life)

What’s interesting to note about the aiso factor from Figure 2 is that as ec approaches 1.0 (i.e., the stress from lubricant contamination is no greater than that produced by clean oil), bearing life increases exponentially, a concept known empirically for many years.

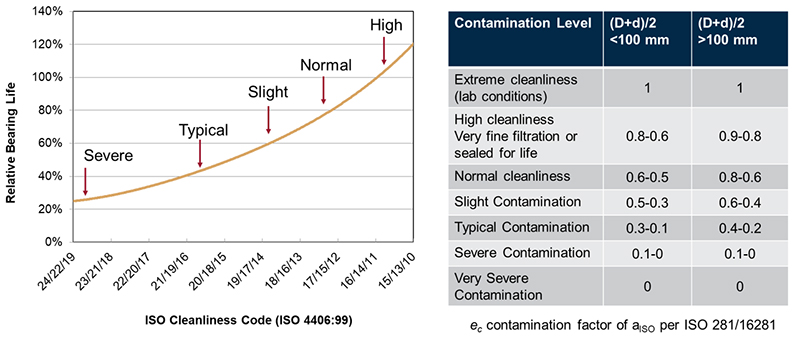

So, how clean is clean? After all, eliminating every last particle from our lubricant is close to impossible. To define “clean,” ISO281:2007 and the associated technical standard ISO 16281:2008 introduced a pseudo-quantitative way of estimating ec based on a definition of the oil’s cleanliness from “extreme cleanliness” to “severe contamination” (Figure 3).

In the standard, an estimate of ec is provided for small bearings with mean-pitch-diameters less than 100 mm (4″) and larger bearings with mean-pitch-diameters greater than 100 mm (4″).

Figure 3: Contamination factor per ISO16281:2008

The ISO 4406 ISO fluid contamination control standard measures fluid cleanliness in lubricating oils.

Those unfamiliar with ISO 4406 can find several well-written articles online that explain the standard.

By comparing the cleanliness factors from ISO16281 to the life-extension tables for element bearing, it is possible to provide a direct correlation between ISO cleanliness per ISO4406 and the ISO16281 standard (Figure 3).

The implication from ISO 281:2007, ISO 16281:2008, and rolling element life extension tables is that optimum bearing life can only be achieved with a Kappa value close to 4.0 and fluid cleanliness of ISO 16/14/11 or cleaner.

What is noticeably absent from the most recent ISO 281 standard is any reference to water contamination’s impact on bearing life. In industries such as steel, pulp and paper, and food manufacturing, water is a pervasive contaminant that can have an even more significant impact on bearing life than particle contamination.

When water enters a lubricant, water is present as either dissolved, emulsified, or free. Free and emulsified water are particularly problematic leading to rust, corrosion, and loss of oil film strength, all of which will impact bearing life.

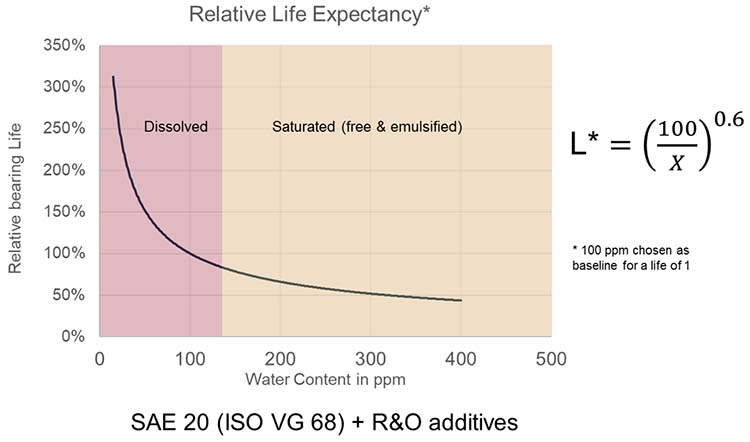

Several studies have been published that look at the impact of water on bearing life. The most well-known is an empirical study from 1977 where the researchers dosed oils of various types with water and measured the number of revolutions before bearing failure occurred under controlled lab conditions (Ref: Richard E Cantley, ASLE Transactions, Vol 20 p244-248).

In this study, the authors developed an empirical formula that linked relative bearing life with water concentration (Figure 4).

Figure 4: Impact of water on rolling element bearing life ASLE Transactions, Vol 20 p244-248

Just like particle contamination, the impact of water in oil is not linear. When water is present in the free or emulsified phase, bearing life drops dramatically by as much as 50%. Conversely, lower water levels below the saturation point at all in-service temperatures can dramatically impact bearing life.

This is why desiccant breathers and water-removal filtration systems are so important whenever water is present in the atmosphere or manufacturing process.

The key to controlling water is maintaining very low relative humidity in the headspace above the oil in a wet sump or oil reservoir. Since the relative humidity of the air and the degree of saturation of the oil are correlated due to the effects of Henry’s Law, high relative humidity in the headspace will mean a high-water concentration in the oil.

Drying the headspace through nitrogen blankets, conditioned air purge, or desiccant breathers is a simple yet effective way to reduce water’s impact on bearing life.

Due mainly to the ramping up of heavy industry during and in the aftermath of World War II, the design, manufacturing, and understanding of the factors that impact rolling element bearing life have progressed exponentially in the last 75 years.

Combined with our greater knowledge of tribology, bearing manufacturers and equipment designers now have a far greater ability to predict bearing life and, in doing so, guide how best to specify, install and maintain rolling element bearings to optimize and maximize bearing life.