In the late 1980s, I took one of the hardest courses of my graduate studies - quantum mechanics. Quantum mechanics is the physics and math behind how all matter is formed and interacts with the world around it. Amongst other things, quantum mechanics can answer some...

Lubricant Analysis

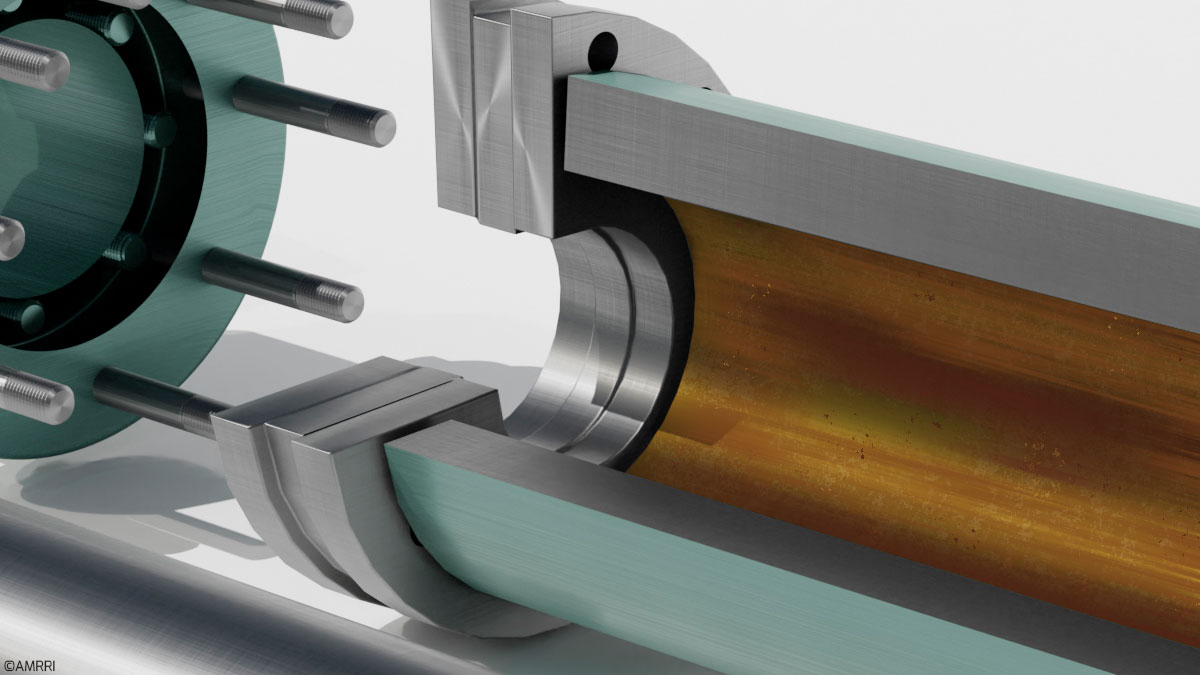

How Varnish Is Destroying Your Hydraulic System (And How to Stop It)

It is common to hear about deposits or varnish in turbine oils, but can other oils also suffer from varnish? The short answer is yes. Once an oil (regardless of its application or type) has been exposed to thermally stressful conditions, contaminants, and severe...

How to Interpret Industrial Oil Analysis Data Like A Pro

In the complex world of industrial machine maintenance, ensuring the health and longevity of industrial equipment is paramount. Industrial oil analysis plays a crucial role in this endeavor, providing valuable insights into the condition of machinery and the quality...

Oil Analysis Program Maturity: Are You Ready for the Next Level?

Oil analysis, often called Oil Condition Monitoring (OCM), has been integral to industrial maintenance programs for more than half a century. Throughout its history, it has contributed to maintenance and improving the profitability of the industries that effectively...

Here’s A More Comprehensive Approach to Revealing Oxidation Root Causes

Typically, when an oil undergoes degradation, the first culprit to be blamed is oxidation. We often hear that the oil has oxidized, producing varnish, leading to its degradation. While this simple statement may seem plausible, it is not the only way oil can degrade....

Online Sensors for Oil Analysis: Benefits, Concerns and Practical Uses

Online oil analysis sensors can prove to be a contentious topic. Social media comments vary from fitting them everywhere to claiming that they will never be a substitute for laboratory oil analysis. Of course, there is a middle ground where online sensors should be...

How to Get Started with Onsite Oil Analysis: A Step-by-Step Guide

Implementing reliability solutions involves solving problems and deciding how to effectively use oil sample test data as a fundamental building block to drive program success. Many decisions confront the end user when they perform their own oil testing and analysis....

How Reliable is Oil Color as an Indicator of Condition?

Most industrial oils, when new, have a clear, translucent color. This typical color is maintained for a period while the product is in its original container and free of harmful effects. However, once the oil is put into service, it undergoes changes that are...

Maximize Oil Analysis with Onsite Tests and Optimized Sampling Intervals

When I first started with condition monitoring in the early 1990s on an open cast iron ore mine, we were blessed to have a geology laboratory to utilize for used oil analysis. In addition, we had the support of a commercial laboratory to whom we could send samples to...

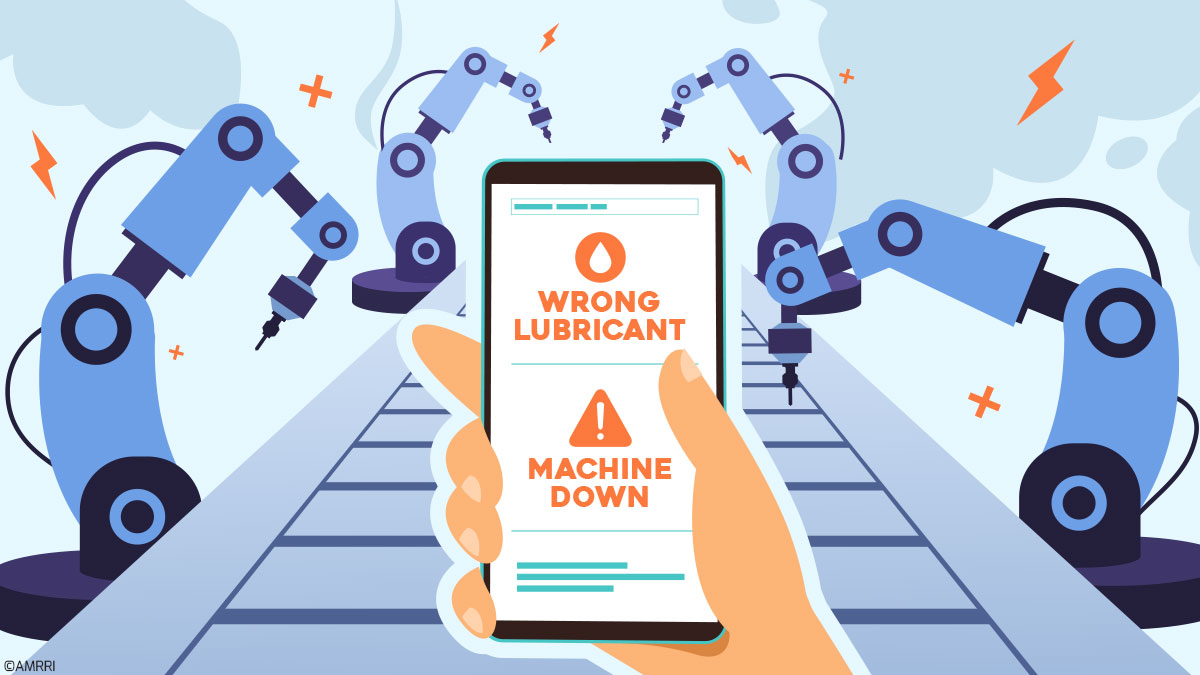

How Lubricant Selection Impacts Degradation and Machine Failure

Many lubrication engineers are faced with finding the most appropriate lubricant for an application. Therefore, they are tasked with selecting the "right" lubricant; subsequently, their decision can influence several outcomes. A lot of the positive results are in the...