In most industrial facilities, over 50% of all lubrication points are lubricated with grease instead of oil. Don't believe me? Just count the number of electric motors in your plant. Unlike most oil-lubricated assets, where OEM recommendations provide at least a...

Greases

How to Extend Bearing Life with the Right Lubricant Choice

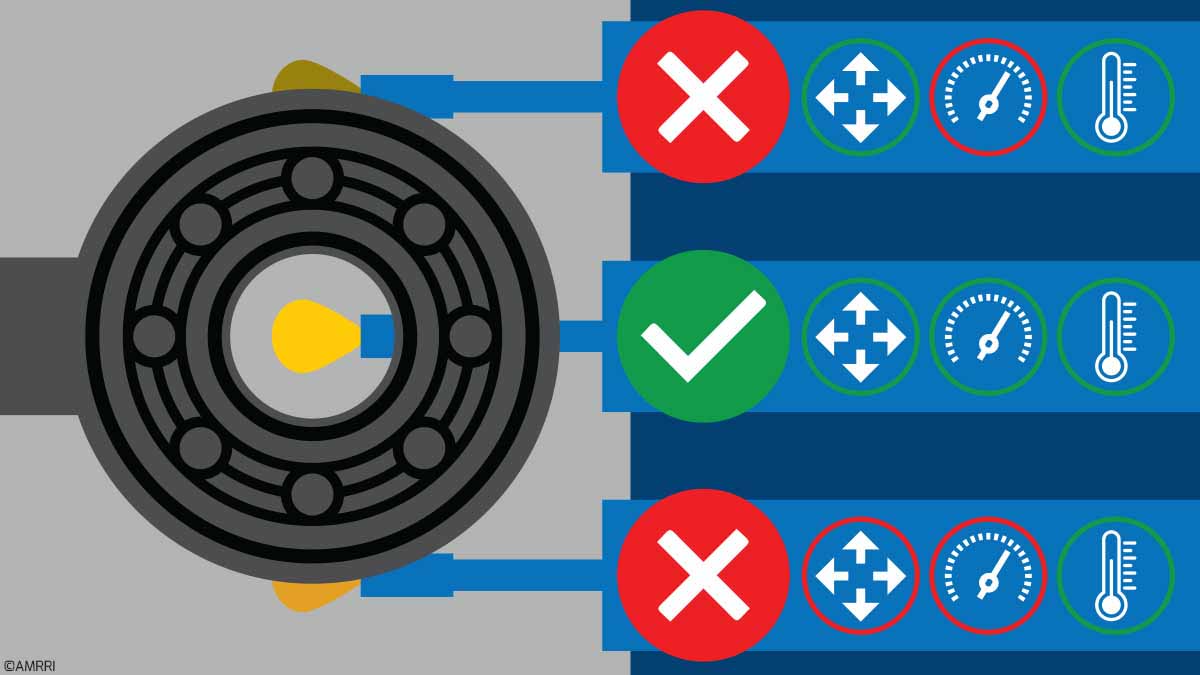

All machines with moving parts have bearings of some type. The bearings may be as simple as flat surfaces working against other flat surfaces, such as the slideway in a machine tool, or they may have sophisticated geometries like a ball screw. Plain and element...

The Humble Grease Nipple: Still Essential After 100 Years

The lowliest and most ubiquitous device in the world of lubrication recently celebrated its centennial anniversary. Designed as a simple yet efficient mechanical gateway device, the grease nipple has only one job: to connect to a manual grease-delivery gun and provide...

Why Grease Analysis is Essential for Predictive Maintenance Success

Grease has been used since ancient times, and new technologies and equipment design require us to improve our understanding and perception of it. These advancements enable those working with grease to recognize better its impact, effective properties, and the proper...

Mastering the Grease Gun: Essential Practices for Effective Lubrication

Grease guns seem simple enough. But how well do you know yours? Do you know how to correctly cartridge and bulk load your gun? Do you know how to expel trapped air from it? Do you know its shot size in cc or cu in (e.g., in cubic centimeters or cubic inches)? Do you...

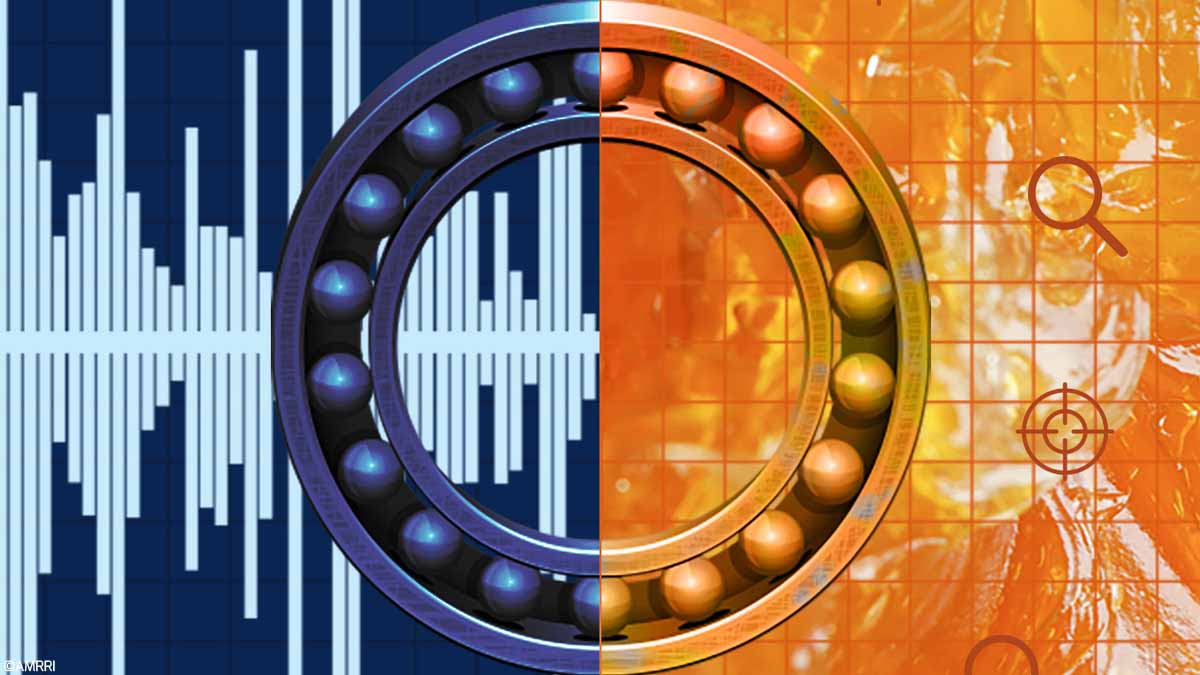

How to Leverage Grease Analysis and Ultrasound for Powerful Results

Years ago, I had my first encounter with one of the predictive maintenance technologies. Since then, I have seen its potential, especially when combined with other PdM tools. Airborne ultrasound for bearing inspection is probably one of the simplest, most versatile...

Adding Grease Analysis to your Onsite Lubricant Condition Monitoring Program

Onsite oil analysis is an effective tool to analyze samples and optimize maintenance activities quickly. As part of a comprehensive condition-based maintenance program (CBM), oil analysis effectively complements other diagnostic technologies like vibration analysis,...

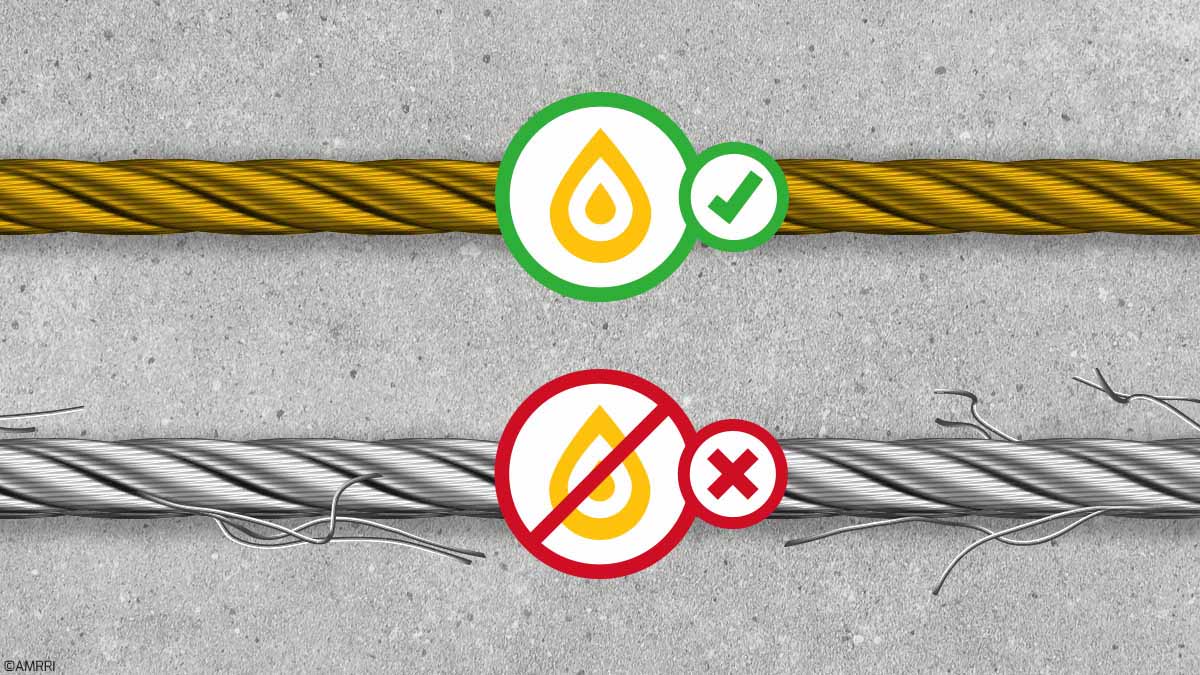

Extending Steel Wire Rope Useful Life through Precision Lubrication

Wire ropes are surprisingly ubiquitous and are used in various industries. I see them daily in Tangier Med Port, where I work. They are visible here in handling equipment in the container terminals. They are used to lift and pull heavy containers in Ship-To-Shore...

Lithium Grease Concern: Paving the Way for Innovative Grease Alternates

In the complex and evolving world of the lubricants industry, we're constantly faced with new challenges. Most end-users have recently suffered from the increasing cost of lubricants and greases. In most instances, these changes have their root cause in supply chain...

How Grease Analysis Helped Expose a Hidden Plant

Those who have worked in or around maintenance and reliability have probably heard about the hidden plant. This term refers to that portion of the productivity of any industry that, for some reason, is wasted and goes completely unnoticed in the eyes of the...