Data, data, and more data. Our industry feeds on data to make decisions, and there's an abundance of condition monitoring tools that allow us to use data to understand the health of operating equipment and detect potential risks of failures. Utilizing core equipment...

Lubricant Analysis

The Elusive Acid Number: What Does It Really Mean?

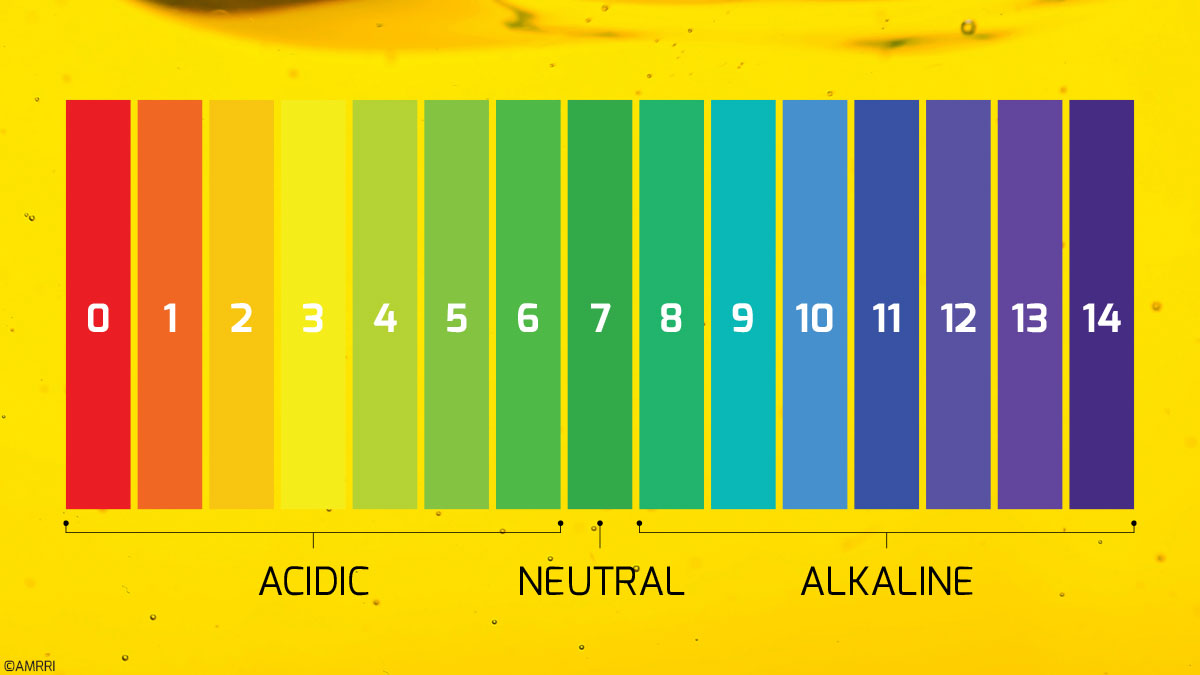

The Acid Number of a lubricant, sometimes called the "Total Acid Number" or TAN, is a commonly reported value for oil analysis and is generally considered an indication of oil aging and degradation. But what does it mean, and how is it determined? Let's break down...

Oil Cleanliness: Why Tiny Particles are Every Machine’s Worst Foe

Is the lubricant circulating through your system free from damage-causing contaminants? Using contaminated lubricants can lead to irreversible equipment damage, shortened life, and unexpected downtime. Instances of contamination can be identified by inspecting the...

How ASTM Standards Set the Foundation for Lubricant Condition Monitoring

The foundation of a lubricant condition monitoring program is the ability to obtain accurate and informative data that can be related to how the machine and lubricant may fail. In the past ten years, many industrial advances have significantly impacted the lubricant...

How Oil Sampling Makes Maintenance Predictable and Effective

Like other condition monitoring techniques, oil analysis is vital in monitoring equipment health and maintaining performance. It aims to detect underlying root causes of failure and early-stage potential failures before they cause significant damage. Oil sampling is...

Reducing Costs, Increasing Production: The Remarkable Impact of Predictive Maintenance

Throughout my years in the maintenance and lubrication industry, I've seen maintenance strategies evolve from reactive, to proactive, to preventive, to now moving their way to predictive. As we move towards the future, we're seeing companies move toward a predictive...

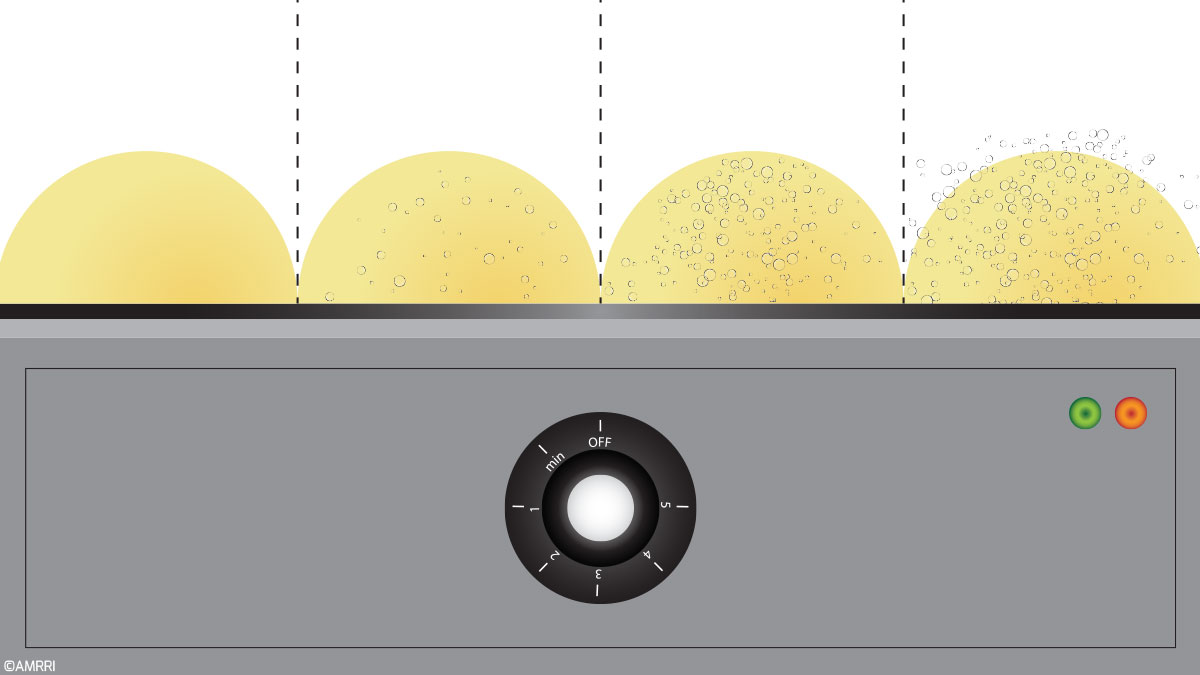

How Reliable and Accurate is the Crackle Test for Oil Analysis?

Why The Most Popular Oil Analysis Test Ever Might Actually Be the Worst Over the years, oil analysis has gone from something adopted by just a few asset owners with critical components to a universal tool to achieve reliability. As oil analysis entered the...

Oil Analysis Blunders: How to Avoid Mistakes in Sample Identification

Lubricants are the lifeblood of machines. Like a blood test, lubricant analysis can provide early warnings of impending failures, far in advance, before it is too late to take timely action. But not all oil samples can give such alerts completely! Only representative...

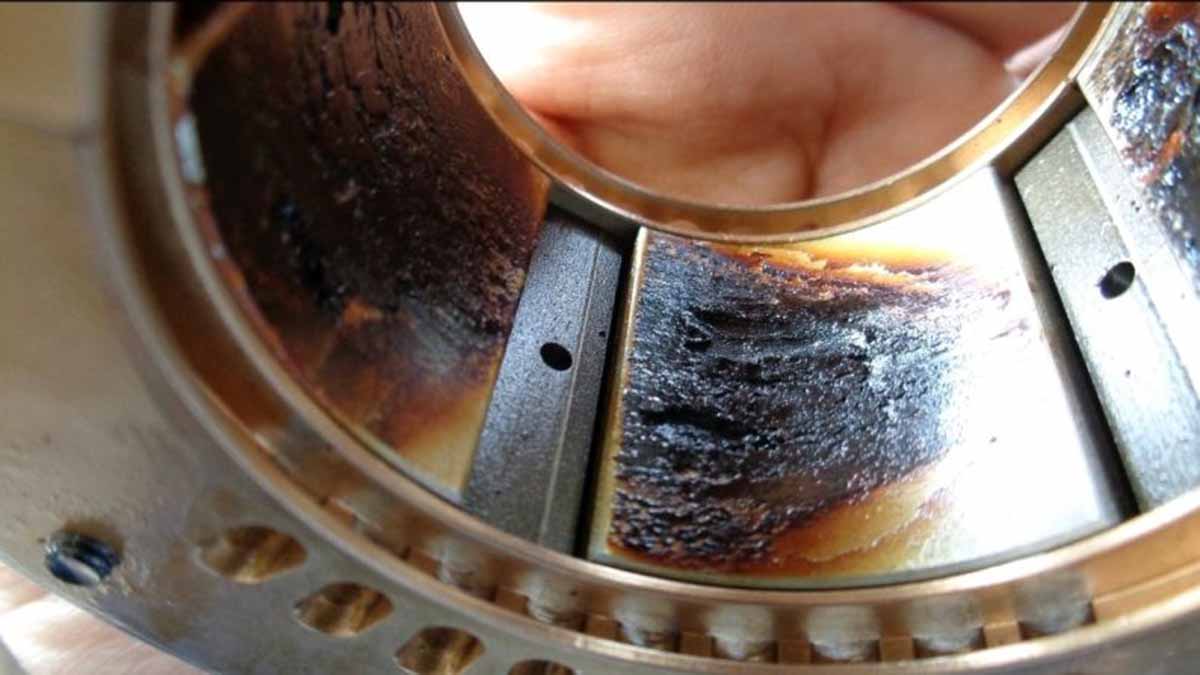

Lube Oil Varnish Detection and Control

Varnish is a type of deposit that forms on the surface of equipment in lubrication systems. It is caused by the oxidation of the base oil and the buildup of additives in the oil over time, forming a sticky, varnish-like substance. Lube oil varnish can cause problems...

How Grease Analysis Helped Expose a Hidden Plant

Those who have worked in or around maintenance and reliability have probably heard about the hidden plant. This term refers to that portion of the productivity of any industry that, for some reason, is wasted and goes completely unnoticed in the eyes of the...