The EGR (Exhaust Gas Recirculation) system recirculates a fraction of the exhaust gases into the intake manifold to lower combustion temperature, reduce NOx emissions, and, in some cases, improve fuel consumption in both diesel and gasoline engines. This recirculation...

Condition Monitoring

Root Causes of Electrostatic Spark Discharge in Modern Lubrication Systems

Understanding Electrostatic Spark Discharge and Its Impact on Lubrication Systems Electrostatic Spark Discharge typically occurs when static is built up in an oil at a molecular level, causing it to discharge in the system and create free radicals, which increase the...

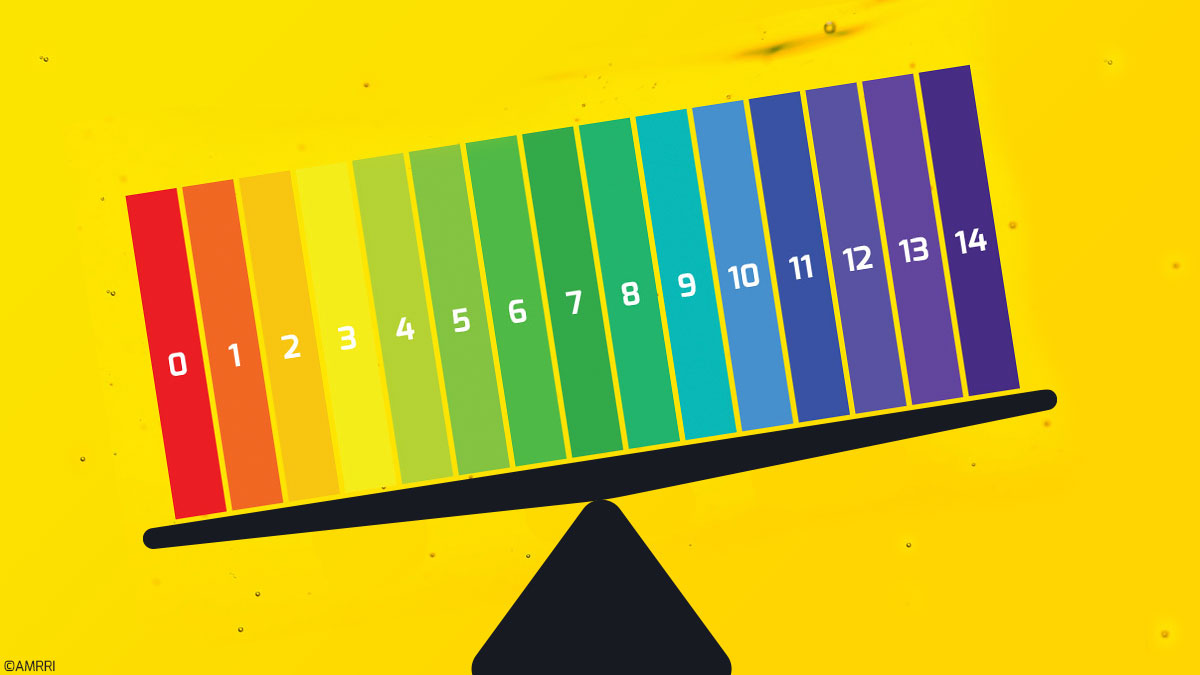

How Acid Number and Base Number Reveal the True Health of Diesel Oils

Lubrication analysis plays a vital role in predictive and preventive maintenance for diesel engines. Among the most informative tests available are Acid Number (AN) and Base Number (BN), two complementary measurements that provide insight into oil health, additive...

How to Extend Oil Drain Intervals Safely Using Condition Monitoring

What is Condition Monitoring and Why Is It Important? In this age of artificial Intelligence and sensors that pop on and off, we often forget about the basics and where things all started. Condition monitoring began as a way to detect anomalies in our equipment using...

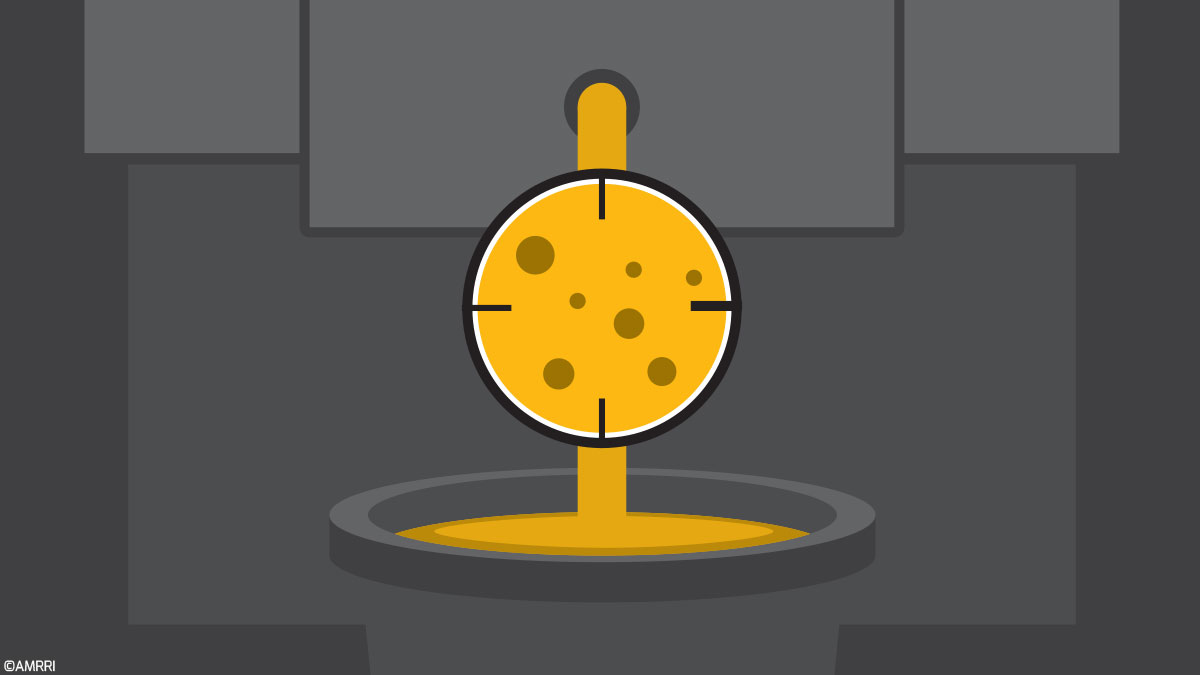

How to Apply the Pareto Principle to Oil Analysis for Smarter Maintenance Gains

In industrial maintenance and reliability engineering, few concepts are as intuitively powerful as the Pareto Principle—also known as the 80/20 rule. Originating from Vilfredo Pareto's observations of wealth distribution, this principle has evolved into a universal...

Turn Maintenance into a Profit Center with an EBITDA Mindset

For over 35 years, I have been at the heart of reliability, lubrication, and operational excellence. In my experience, siloed decision-making between maintenance, HSE, and procurement often results in inefficiencies, increased risks, and missed opportunities for...

How Machine Learning is Redefining Fluid Analysis for Predictive Maintenance

Traditional fluid analysis relies on pre-set flagging limits to evaluate the severity of a sample. These limits, refined over time through statistical analysis, provide a baseline for assessing whether test results indicate any maintenance needs. If a sample falls...

How to Select Oil Analysis Tools That Align with High-Value KPIs

Oil analysis is critical to any reliability program, serving as an effective predictive tool for potential equipment failures. When properly deployed, oil analysis has the power to enhance maintenance practices within industrial and fleet settings. This article will...

The Case for a Detailed and Structured Lubrication Plan

Proper lubrication of equipment, machinery, and devices is essential to ensure mechanical systems' smooth operation and longevity. This process must be based on rigorous procedures, precise calculations, and various crucial factors to determine the correct amount of...

Optimizing Alarm Limits to Combat Alarm Fatigue in Oil Analysis Programs

Examining oil analysis programs – both off-site and onsite programs across various industries- it is observed frequently that oil analysis abnormal alarm observations and recommendations are not being acted upon promptly. The ability of reliability teams to ignore the...