Ferrous debris, put simply, refers to the metallic particles or fragments, mainly composed of iron (Fe), within a sample of lubricating oil.

Prematurely identifying ferrous debris can lead to identifying wear and tear within the system – which, when left unresolved, can lead to catastrophic equipment problems.

Determining the amount of ferrous debris in a sample has always been a challenge for condition monitoring laboratories and even at the end-user facilities.

Historically, there have always been challenges with spectroscopic methods not fully analyzing the ferrous debris load; both ICP-OES (Inductively Coupled Plasma – Optical Emission Spectrometry) and RDE (Rotating Disk Electrode) only fully analyze particles lower than about 10µm in diameter.

Identifying Ferrous Debris: Considering Two Methods

In 1985, the Swansea Tribology Centre introduced the solution to this problem: the PQ™ (Particle Quantifier) Ferrous Debris Monitor. Since then, the PQ™ has become an essential component of oil condition monitoring programs and is used in most laboratories specializing in this worldwide.

The PQ™ is a sensitive magnetometer that measures the influence on a magnetic field (known as the Hall effect) that a sample exerts, thus providing a quantitative (though unitless) result of the ferrous wear in the sample. This result can be trended with acceptable linearity over a wide range of ferrous debris concentrations and particle sizes.

With all the advantages and benefits of PQ™, some serious limitations exist. PQ™ allows samples to be measured in the bottle, but when doing so, only the bottom centimeter or so is analyzed.

Standards are only available from the manufacturer and are not NIST (National Institute of Standards and Technology) traceable. Finally, there is the issue that the results are unitless – the PQ™ Index is a dimensionless number.

To meet these limitations, newer instruments have been developed. One of which is the new Poseidon FerroQ™. The FerroQ™ uses a set of coil windings, one for measurement and one for reference.

When the sample is inserted, any ferrous material in the oil or grease sample changes the inductance of the measurement coil relative to the reference coil.

A sensitive signal conditioning circuit detects those minuscule changes in the inductance of the measurement coil, and the embedded processor interprets this signal to provide a mass/volume output based on calibration standards.

Reporting Differences

Products such as PQ™ devices and some PPM devices often use a single coil below the sample. This results in a device highly sensitive to particles at the bottom of a sample and insensitive to those at the top. FerroQ™ measurement coil surrounds the sample, providing uniform sensitivity and superior repeatability.

Finally, the FerroQ™ reports results in mg/kg and utilizes NIST-traceable standards back to a primary iron standard. This gives a result that is quantifiable and more adequately meets quality standards.

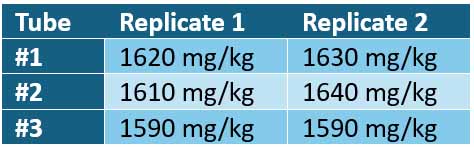

To confirm the traceability and accuracy of the results from the FerroQ™, 0.0151g of Iron Powder, <10 µm, ≥99.9% trace metal basis from Sigma Aldrich was prepared in 10.0007 g total of a UV reactive resin. The theoretical result was 1510 mg/kg.

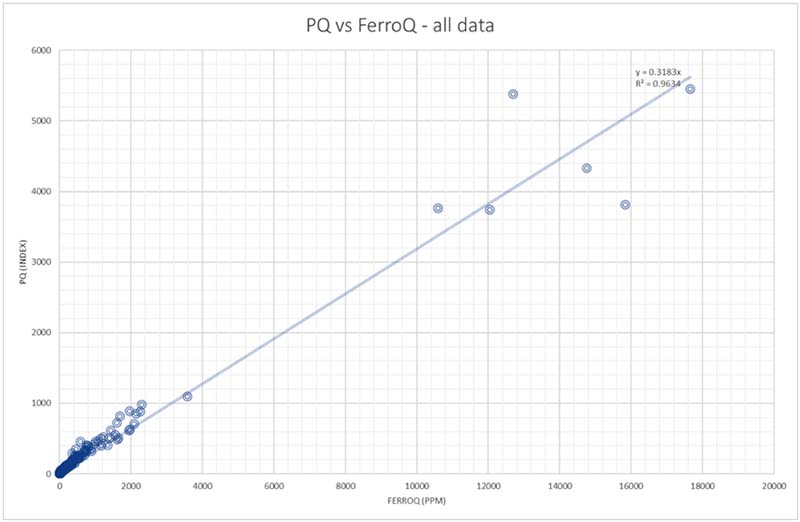

Some laboratories desire to switch from the venerable PQ™ to the FerroQ™. To determine this, 1291 comparisons were made.

Using all data, results show that above 1000 PQ™ Index, the data did have a skew. This is likely due to the PQ not analyzing the entire sample, only the bottom ~1 cm of the sample.

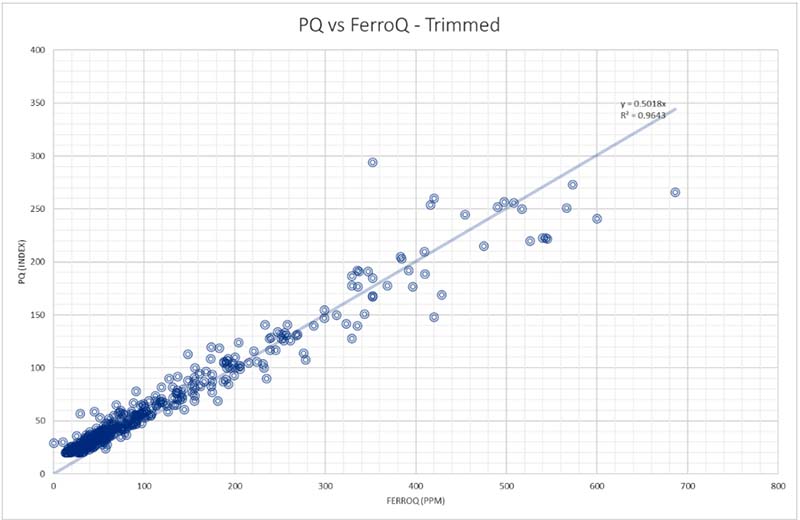

Removing this data shows a definite correlation between the two methods:

In summary, the FerroQ™ technology will perform similarly to the PQ™ technology. This, coupled with the FerroQ™ having NIST traceable standards, reporting in mg/kg, and analyzing the entire sample (as opposed to only the bottom), may be a superior method to the venerable PQ™.

Testing laboratories and end-user facilities can decide what test method and product is used to determine ferrous debris in oil samples, and evaluating benefits, advantages, and limitations must be considered, as well as what reported results are required.