Standby Generators Need Proactive Fluid Analysis to Stay Reliable

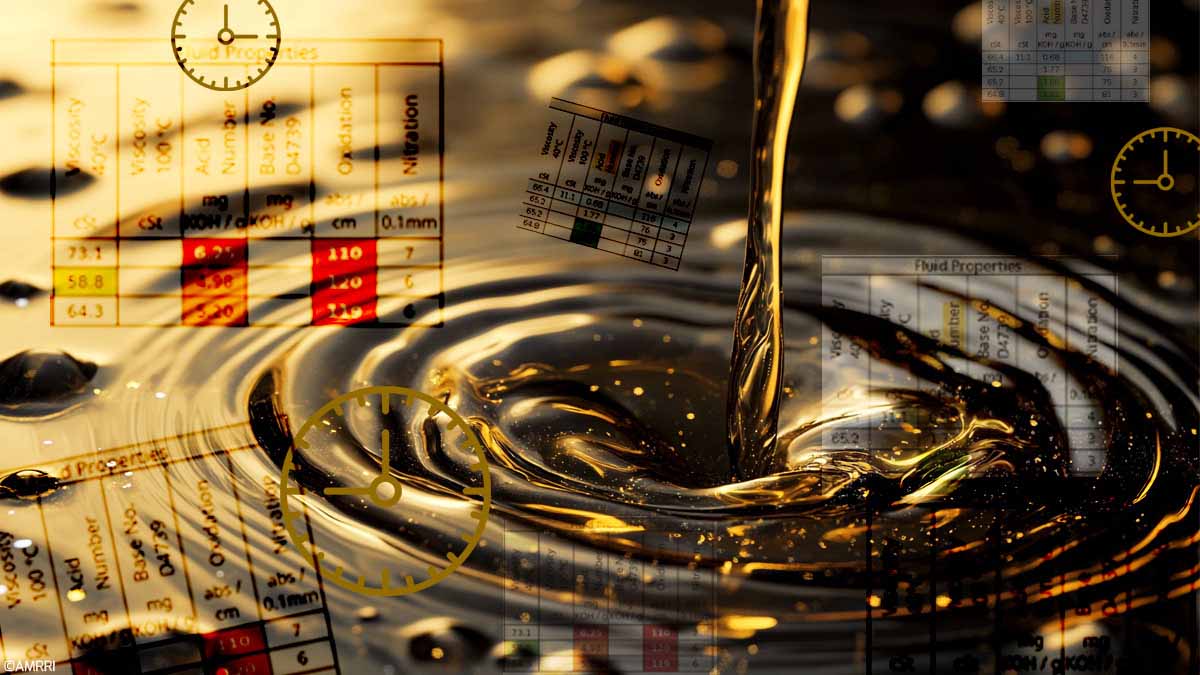

From Oil Samples to Algorithms: Leveraging AI and Automations

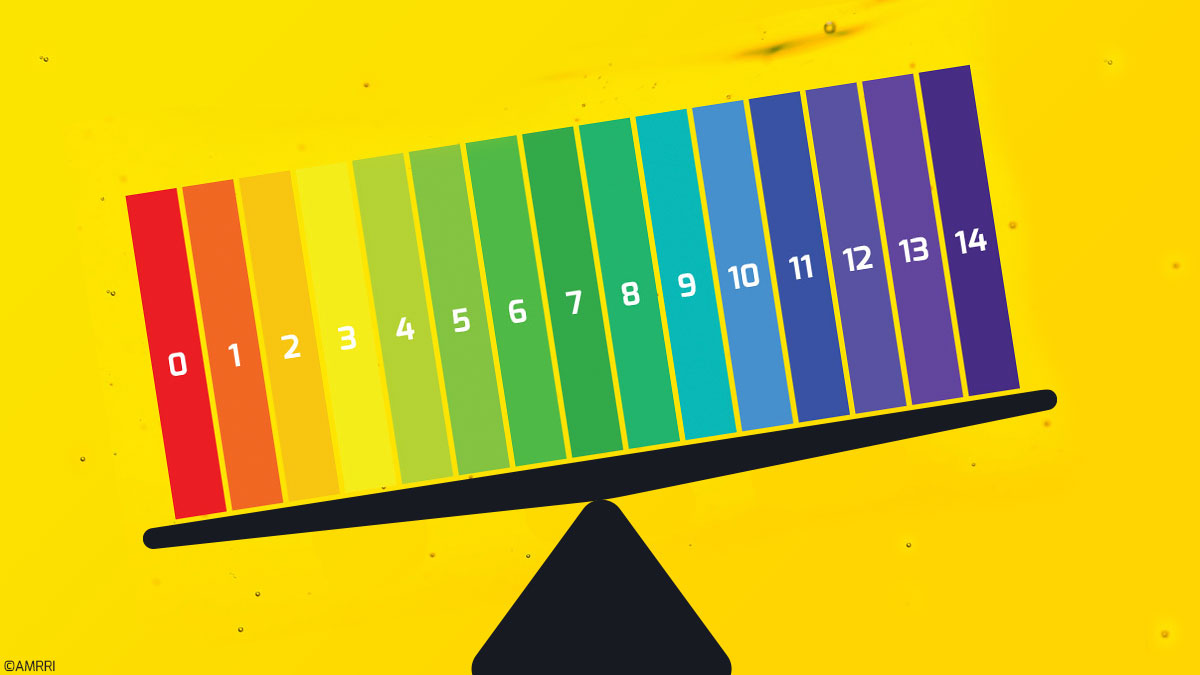

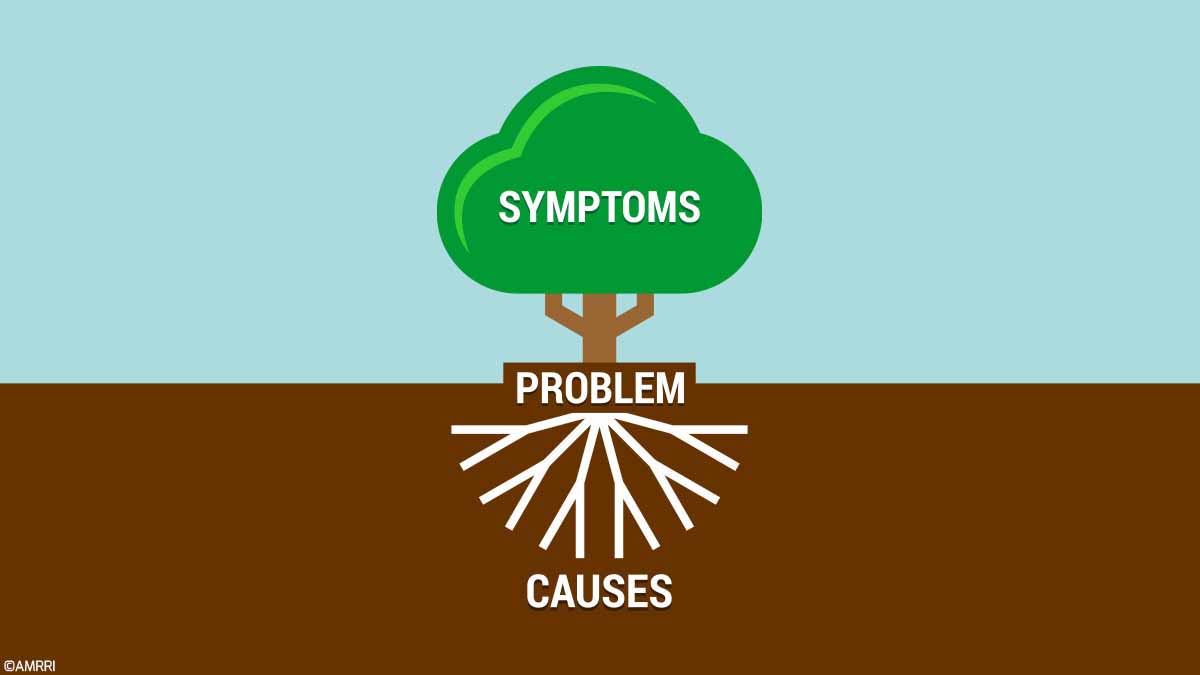

How Acid Number and Base Number Reveal the True Health of Diesel Oils

Data-Driven Strategies to Optimize Lubricant Drain Intervals

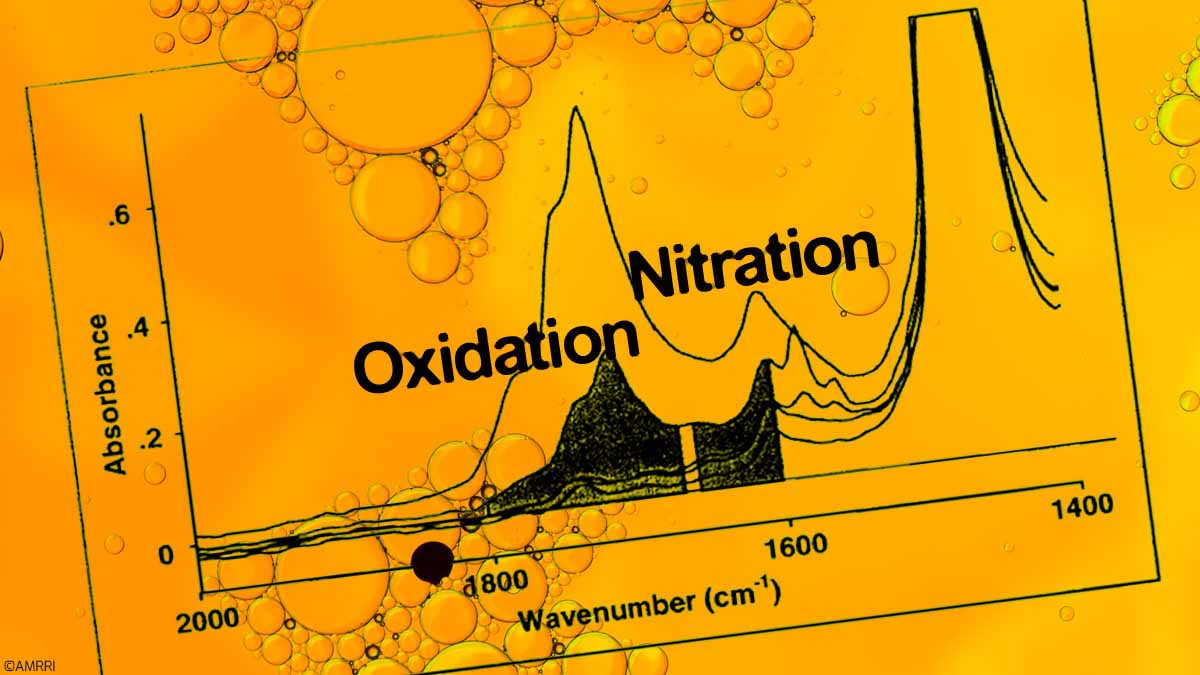

How Detecting Oxidation and Nitration Early Protects Equipment

Contamination Control: Improve Cleanliness, Prevent Failures with Particle Count

How Machine Learning is Redefining Fluid Analysis for Predictive Maintenance

Cold Weather Equipment Care: Essential Fluid Testing Steps

Why Grease Analysis is Essential for Predictive Maintenance Success

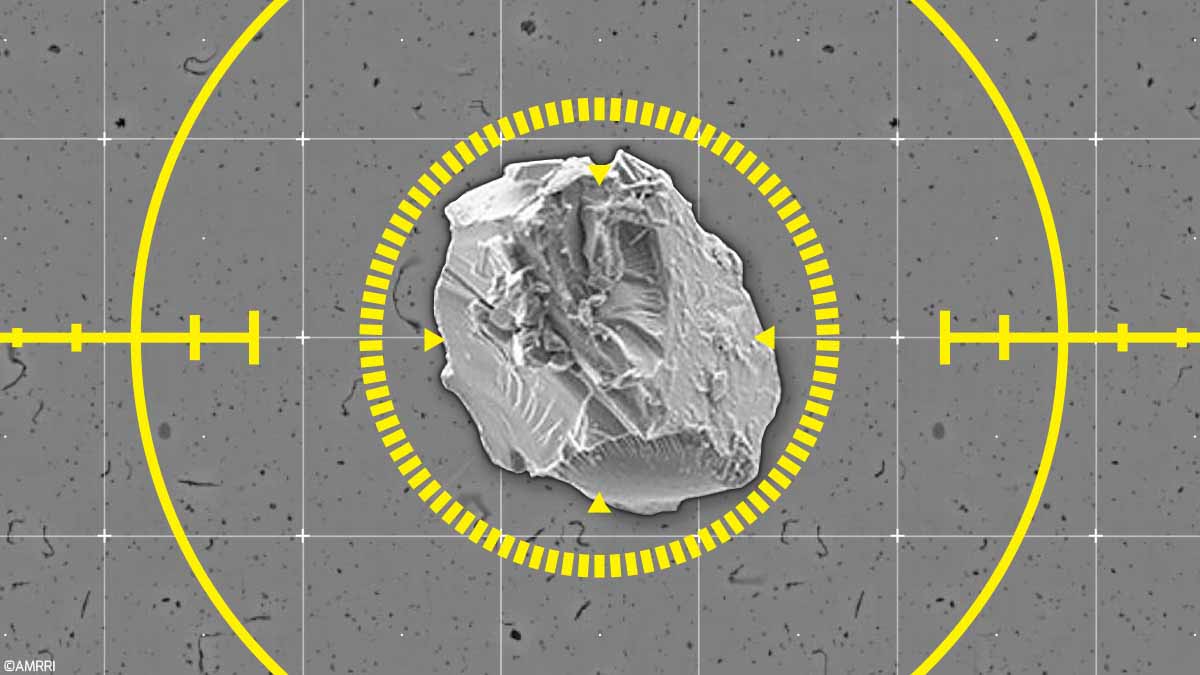

How to Improve Maintenance Decisions Using Analytical Ferrograms

Uncovering the Unseen: Advanced Oil Testing for Critical Insights

Assessing Spectroscopic Methods to Analyze Particles: PQ vs. FerroQ

The Bottom Line of Reliability: Fluid Analysis Cuts Maintenance Costs

Advanced Methods for Detecting and Measuring Soluble and Insoluble Varnish

Oil Analysis Program Maturity: Are You Ready for the Next Level?

Why Your Maintenance Management Needs to Embrace Data Integration

Oil Cleanliness: Why Tiny Particles are Every Machine’s Worst Foe

Reducing Costs, Increasing Production: The Remarkable Impact of Predictive Maintenance