Grease has been used since ancient times, and new technologies and equipment design require us to improve our understanding and perception of it. These advancements enable those working with grease to recognize better its impact, effective properties, and the proper methods for testing grease samples, shedding new light on its applications and benefits.

The Importance of Monitoring Grease

Through these continuous technological advancements, the formulations of grease have significantly expanded, making it a crucial component to monitor when maintaining and enhancing the performance of modern equipment across various industries.

Greased equipment in mobile and industrial industries is getting more scrutinized as predictive and proactive maintenance are becoming the standard. To this end, greased components need to be viewed as crucial as any lubrication program, and any downtime resulting from failed greased components should be thoroughly investigated to determine the cause of the failure. Was it environmental conditions, over or under lubrication, incorrect grease, or exceeding the equipment design capacity?

The Benefits of Grease Analysis

By testing grease components, analyzing and recognizing wear trends, and determining lubricant properties, we can increase the capacity to react to potential equipment failures. These failures can lead to a reduction in production and compromised safety. While many industry sectors view greased components as replaceable or run-to-failure parts, testing these components allows us to become more informed.

Technological advancements now allow for precise determination of wear concentration and lubricant conditions. With routine testing, we can identify and provide the information to better schedule lubrication intervals, plan equipment repair, and determine the best time to replace components, thus increasing uptime and productivity. With this knowledge, industries can effectively conduct Root Cause Analysis (RCA) to prevent future failures.

Technological advancements now allow for precise determination of wear concentration and lubricant conditions. With routine testing, we can identify and provide the information to better schedule lubrication intervals, plan equipment repair, and determine the best time to replace components, thus increasing uptime and productivity. With this knowledge, industries can effectively conduct Root Cause Analysis (RCA) to prevent future failures.

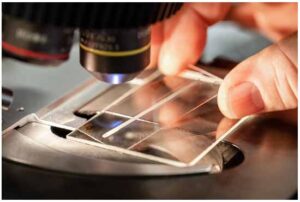

Today, failure can be prevented with as little as 2 grams of grease. ATSM D7718-11 Standard Practice for Obtaining In-Service Samples of Lubricating Grease was created to make the process more accessible. This standard describes the method to obtain in-service grease samples that can be tested for trending purposes.

The basic tests, which include Ferrous Density, FTIR, color, and water, are used as a screening tool.

In addition, more complete evaluations of grease include testing for Total Water, Remaining Useful Life (RUL) Antioxidants Levels, Microbial, Elemental Metals, and Extrusion Values. These tests’ key component is for each to be compared to a known provided baseline sample.

The Wear that Grease Testing Identifies

Data obtained from grease evaluations can assist in identifying not only the characteristics of the grease itself but also the quality of the base oil it provides for lubrication.

Effective grease should lead to minimal wear metals. Elevated levels of antioxidants with extended Remaining Useful Life (RUL) across several samples may indicate a need to reassess current relubrication schedules. Proactive monitoring of these factors can reduce lubrication expenses and ensure consistent reliability.

On the other hand, a high wear metal concentration could be a sign of an increase in lubrication, as this would lead to the base oil not providing the correct fluid film for protection.

On the other hand, a high wear metal concentration could be a sign of an increase in lubrication, as this would lead to the base oil not providing the correct fluid film for protection.

The National Lubricating Grease Institute (NLGI) grade measures the hardness of grease in relation to pumpability and soap structure, and the ISO Viscosity grade provides the proper fluid lubricant film protection. In addition, tools such as the Analytical Ferrogram give insight into the type of wear being generated and are a great aid in the RCA process.

For example, when analyzing a recent grease sample with severe levels of Ferrous Debris for a crane wheel bearing, it was recommended that an analytical ferrogram be performed. The amount and type of wear observed indicated insufficient lubrication was occurring, yet regreasing was being conducted at regular intervals.

There was no indication that the bearing was in failure mode. However, an abundance of fresh wear was generated. And, since the lubrication regime was boundary, the base oil viscosity plays an important role. Usually, with a slow-moving crane bearing, a base oil Viscosity of ISO 320 or 460 is standard.

This grease being tested had a base oil Viscosity of ISO 220, which caused an increase in wear as the lubricant film was insufficient for the heavy loading occurring. A recommendation was made to contact the crane manufacturer for further guidance on the proper grease for that operating condition.

Looking through this new lens of analyzing grease, adding regular testing on grease components can help reduce unnecessary downtime and increase overall safety.