As a fluid analysis laboratory, our ongoing mission is to improve the quality of our analysis and interpretation. To do this, POLARIS Laboratories® performs statistical analysis on our test methods and results to evaluate typical parameters and establish thresholds for our tests.

These efforts help us support customers to optimize machine health and equipment reliability through oil analysis. One of the tests we’ve been able to perform advanced statistical analysis on is our methods for detecting varnish in industrial systems.

Varnish, a lacquer-like substance that adheres to metal surfaces, results from the depletion of antioxidant additives within the oil. Once the antioxidant levels drop below a certain threshold, varnish can form faster than it can be controlled, leading to temperature stress and hot spots.

These hot spots can further result in filter plugging microdieseling and can quickly lead to catastrophic failure if not detected early and addressed.

Membrane Patch Colorimetry (MPC) to Identify Varnish

One of the standard tests performed to identify varnish is the Membrane Patch Colorimetry (MPC) or ASTM D7843 (Standard Test Method for Measurement of Lubricant Generated Insoluble Color Bodies in In-Service Turbine Oils using Membrane Patch Colorimetry), which measures the varnish content currently concentrated in the oil sample.

The test is performed by heating the sample to 60-65 °C for 23 to 25 hours. The sample is then placed in the dark, away from UV light, for 72 hours.

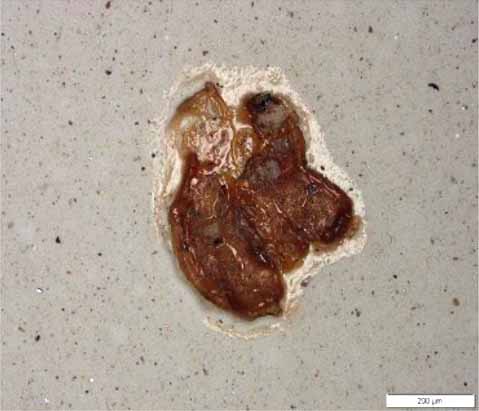

After the incubation period, the sample is mixed with Petroleum Ether, stirred to allow a complete mixture, and then filtered onto a 47mm, 0.45-micron-size membrane patch. The patch is placed in a location free of dust and heat and air-dried for about three hours.

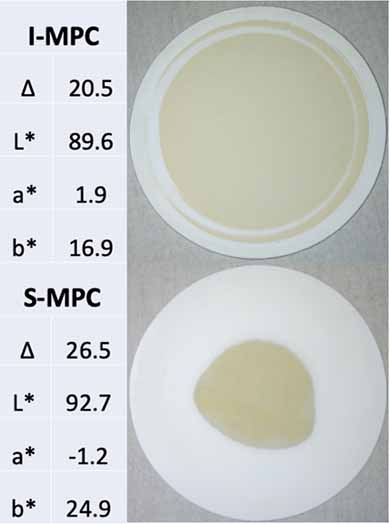

Once the patch has been dried, a colorimeter is used to detect the color of the patch, and the CIE Lab ΔΕ and L*a*b* calculations are used to report the color of the patch.

Statistical Analysis Results in Advanced MPC Method

Through our statistical analysis of the standard MPC method, we’ve been able to implement improvements to develop an advanced MPC method, which has the potential to measure soluble varnish in turbines, hydraulics, and compressors using R&O (Rust and Oxidation) formulations.

The new method was introduced along with the existing MPC method as a tool for customers to proactively identify and correct their oil’s potential to develop both soluble and insoluble varnish.

Soluble vs. Insoluble: The Value in Detecting the Difference

The difference between detecting soluble vs. insoluble varnish is that unlike the standard MPC method (ASTM D7843, mentioned above) in which Petroleum Ether is used to dilute the oil sample, this diluent can wash off the soluble varnish that is at the initial stages of varnish formation.

For this reason, we do not use any solvent or diluent when performing the soluble varnish test. As soon as the sample is removed from the oven, a quick drop of sample is taken and placed on the patch; then, it is immediately placed in the dark to dry.

The purpose of detecting soluble varnish is to capture as much of it without risking it being washed off with a solvent or diluent. The goal is to be able to detect when the varnish is starting to form and proactively work to remove it.

This results in cost savings in equipment downtime, maintenance, labor, production loss, and labor.

Once the varnish has begun to plate out and form agglomerations, the formation of varnish is at advanced stages, making it more difficult to remove. Insoluble varnish leads to operational issues within the system and can take longer to remove and clean the system.

Discovery of New Limits Based on Statistical Methods

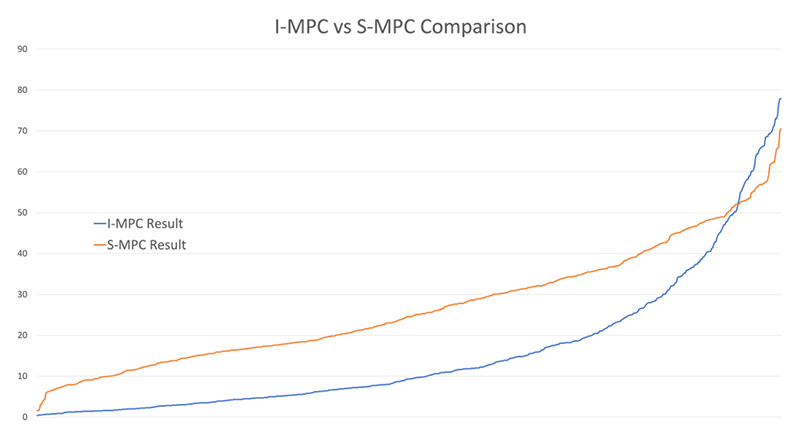

While our new method was introduced with the same severity range as ASTM D7843, we have collected enough data to confidently establish new limits based on the same statistical methods used for other ASTM tests.

Our findings show that the new method tends to produce higher values, and for this reason, we consider the results abnormal when they exceed a value of 25, whereas the threshold for the original method is 15.

Along with our new MPC method, we also began reporting L*a*b* values to quantify color value. The L* value (black-to-white ratio) indicates microdieseling, electric spark discharge, and/or electric static discharge.

Our new findings strongly correlate with our original MPC method in which an L* value will now be considered “low” when the value is below 75, compared to 100 in the original MPC method.

When reporting L*a*b values, the b* value (yellow) indicates the fluid has the potential to form gummy, sticky varnish deposits. Abrasive contaminants and wear can adhere to these agglomerations and increase wear on the machine.

Similarly, our findings with the new method strongly correlate with the original method, and this value will now be considered “high” when it exceeds a value of 35, compared to the 15-20 in the original MPC method. The value will be flagged as yellow Severity 2.

The new MPC method has the potential to measure soluble varnish. However, many other variables can influence the results. POLARIS Laboratories® is now providing these variables on the lubricant analysis reports delivered to fluid analysis customers if the new MPC method is high and will not recommend any action be taken unless results for the original method are high.

POLARIS Laboratories® strives to continually improve our methods and interpretation of the analysis conducted on fluid samples to assist our customers in catching varnish contamination sooner, saving more equipment, and improving reliability.