Lubrication analysis plays a vital role in predictive and preventive maintenance for diesel engines. Among the most informative tests available are Acid Number (AN) and Base Number (BN), two complementary measurements that provide insight into oil health, additive performance, and the potential for damaging conditions inside the engine.

The true picture of oil health emerges only when acid number and base number are analyzed together.

While historically BN has been the primary focus in diesel applications, changing lubricant formulations and emissions-driven oil designs have made AN testing equally critical. Together, AN and BN monitoring support condition-based maintenance strategies, reduce unplanned downtime, and optimize oil drain intervals.

Understanding the Fundamentals of Acid Number and Base Number

Acid Number (AN) measures the amount of acidic compounds in a lubricant. Acids can form from oxidation, nitration, or sulfur byproducts of combustion, and they can be highly corrosive to internal components if left unchecked. A rising AN signal indicates degradation and potential corrosive wear.

Base Number (BN) measures the alkaline reserve in an oil or the capacity of additives (primarily detergents) to neutralize acids formed during engine operation. As the oil ages and these additives are consumed, the BN value declines.

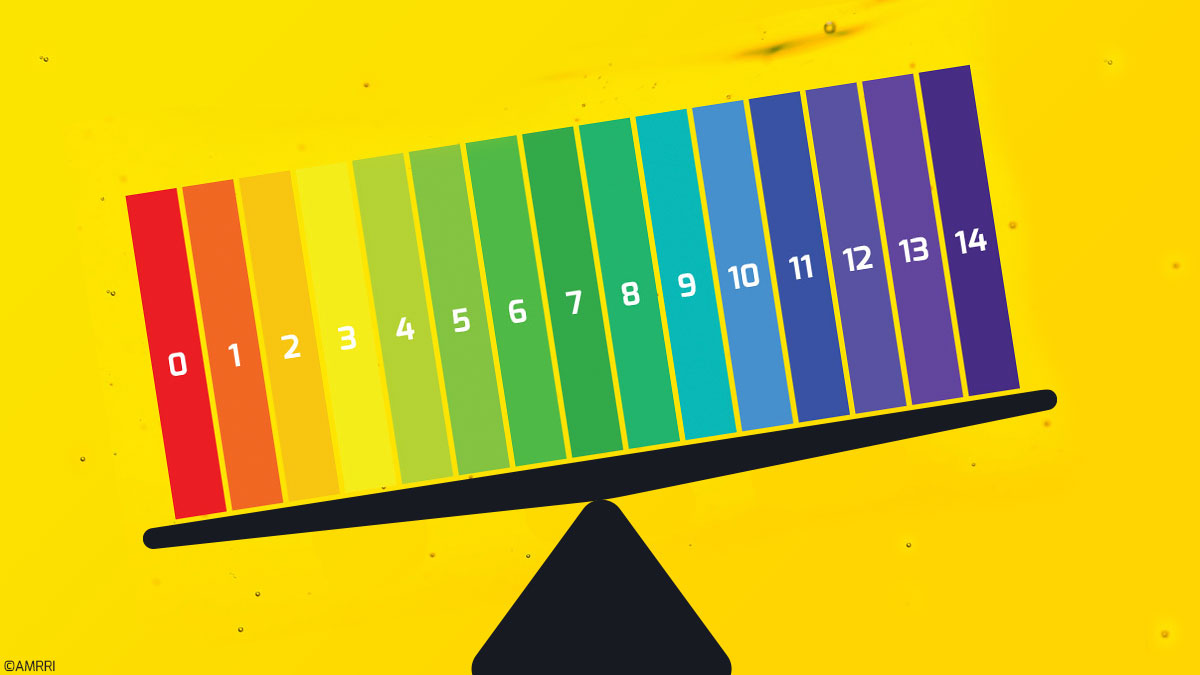

Both parameters are critical for oil condition monitoring: BN tracks how much “protection” against acids remains, while AN indicates how much corrosive material has already accumulated, and is the preferred test due to its ability to measure at lower levels, more on this later in the article.

The Role of Acid Number and Base Number in Diesel Engine Performance

In diesel applications, the balance between AN and BN provides a powerful indicator of lubricant condition. A healthy oil will show a gradually decreasing BN alongside a relatively stable, slowly increasing AN. When BN drops too low, acids are left unneutralized; when AN rises too high, corrosive attack accelerates.

Modern low-ash diesel oils have changed the rules – tracking both acid and base numbers is now essential for accuracy.

The challenge in today’s engines is that newer low-SAPS (sulfated ash, phosphorus, sulfur) formulations (introduced to prevent plugged diesel particulate filters (DPFs) and EGR failures) start with lower BN values and of`ten deplete more slowly. Some products are designed for emissions compliance and reduced ash formation due to low starting base numbers. As a result, relying solely on BN alone can be misleading.

In these cases, monitoring AN is vital. Even while BN remains relatively stable, AN can increase due to oxidation, fuel dilution, or coolant leaks. This dual tracking is why an increasing number of operators in Europe and globally now perform both AN and BN testing on diesel engine oil samples.

Impact on Oil Drain Decisions

One of the most practical applications of AN and BN analysis is in determining oil drain intervals. Traditional time- or mileage-based drain schedules often result in premature oil changes (waste) or delayed changes (risk of damage). Condition-based monitoring, by contrast, uses AN and BN data to identify the oil’s true remaining useful life.

AN does not increase linearly. Instead, it follows a curve: a slow, gradual rise at first, followed by a sharp increase once antioxidants are depleted. This inflection point represents the end of the oil’s life, when oxidation accelerates and corrosive wear risk rises rapidly. Effective condition-based maintenance requires identifying this inflection point and scheduling oil changes 10–20% before the oil reaches it.

By trending BN depletion alongside AN increase, maintenance teams can strike the right balance and extend drains safely while avoiding the steep escalation of wear and damage.

Standard Test Methods for Measuring Acid Number and Base Number

Several ASTM methods are commonly used for AN and BN measurement:

- ASTM D2896 (BN) – Uses a potentiometric titration with perchloric acid; highly sensitive but can give elevated values in used oils. (This test is designed for new oil only and should not be used for used oil, as the acid used in the titration will react with wear metals in used oils)

- ASTM D4739 (BN) – Uses hydrochloric acid; considered more representative of remaining alkalinity in used oils

- ASTM D664 (AN) – Potentiometric titration with KOH, used to determine acidic constituents in petroleum products

- All test methods report mg KOH/g

The choice of method depends on oil formulation, application, and whether the sample is new or in service. Many labs report both D2896 and D4739 for BN to give operators a complete picture. However, D2896 is not recommended as it is not a suitable method for new oils; most labs in Europe do not perform D4739 and use a modified method (different solvent) for D2896.

As modern diesel oils begin with lower base numbers, traditional test methods lose precision – making careful method selection critical.

BN was designed for fluids with a starting BN of ~ 12 mg KOH/g. Now they have a starting value of about 6 mg KOH/g. Neither method for measuring BN is accurate at lower levels.

On the other hand, AN was designed for lower levels (>4 mg KOH/g) and gives a better discrimination of the new fluids as they age. AN is a titration with potassium hydroxide (KOH). The KOH reacts mainly with carboxylic acids.

Carboxylic acids are degradation products caused by the oxidation of lubricating oil and additives. Thus, AN, in conjunction with FTIR (Fourier-transform Infrared) oxidation, gives an excellent definition of the oxidative state of a lubricating fluid.

Engine Damage Risks from Imbalanced Acid and Base Numbers

If AN and BN trends are ignored, several damaging conditions can occur inside a diesel engine:

- Corrosion of bearings and liners from acidic byproducts attacking metal surfaces

- Ring and cylinder wear from both acidic attack and ash formation when BN is insufficient

- Accelerated wear and deposits from oxidation products, sludge, and varnish as AN spikes

- Reduced reliability and costly downtime due to preventable mechanical failures

Finding the Critical Balance

As diesel engine oils evolve to meet emissions and performance requirements, maintenance practices must adapt. Relying on BN alone is no longer sufficient, particularly with low-SAPS, ultra-low-ash formulations. By monitoring both AN and BN, operators can accurately track oil condition, optimize drain intervals, and prevent corrosive wear.

Fluid analysis isn’t just about data; it’s about actionable insight. The balance between AN and BN is one of the most powerful tools in the maintenance toolkit, ensuring engines operate efficiently, safely, and for the long haul.