I had a laboratory manager, over twenty years ago, complain to me that he wished I would stop pushing particle counting, as he was getting annoyed by clients asking for it after my courses. In his view, particle counting was necessary primarily for hydraulic oils and...

Oil Sensors

Tan Delta Systems Introduces New SENSE-2 Oil Monitoring Technology

Tan Delta Systems has announced the launch of its newest product, SENSE-2, an oil condition monitoring system aimed at the manufacturing and industrial sector. The company calls SENSE-2 "an innovative new system designed to optimize maintenance scheduling and...

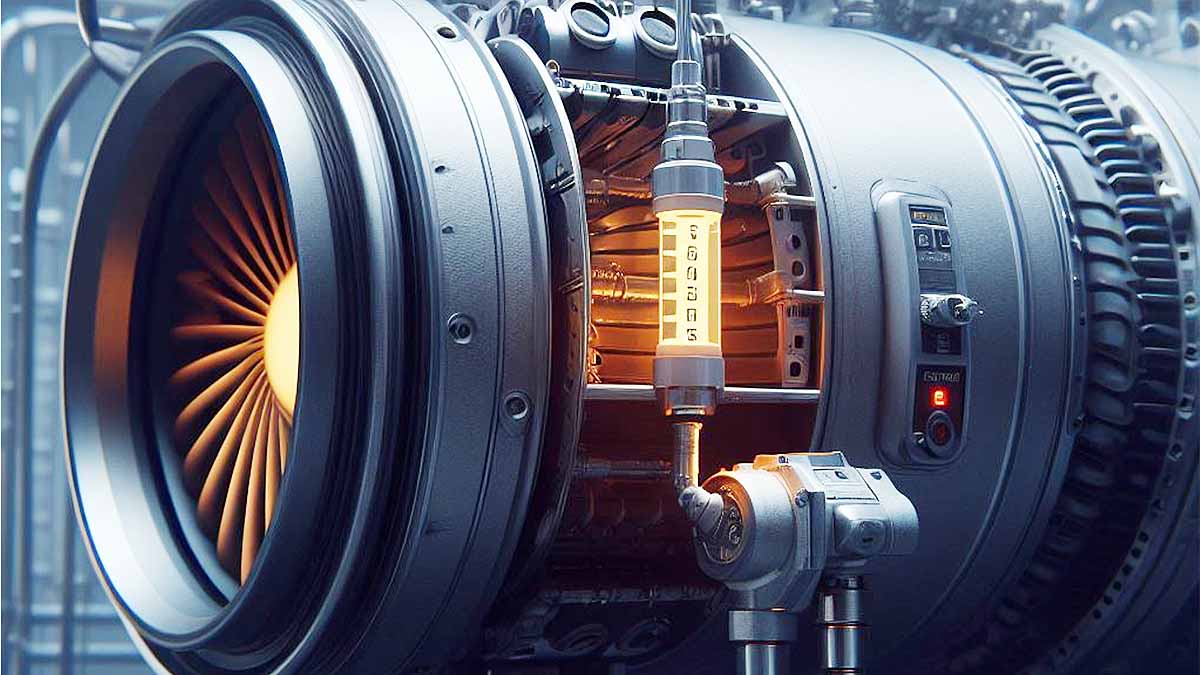

Real-Time Turbine Oil Condition Monitoring with Mid-Infrared Sensor Technology

Condition monitoring sensors for lubricants have been an established technology for numerous decades, playing a vital role in safeguarding some of the most essential machinery worldwide, including their incorporation into certain premium automotive models. However, it...

How Reliable is Oil Color as an Indicator of Condition?

Most industrial oils, when new, have a clear, translucent color. This typical color is maintained for a period while the product is in its original container and free of harmful effects. However, once the oil is put into service, it undergoes changes that are...

Paper Machine Oil Condition Monitoring Benefits and Case Study

Oil analysis on oil reservoirs, such as a paper machine, provides much more value than most maintenance managers realize. Regular reservoir oil sampling can provide the following: Reactive information, such as a spike in wear metals identifying a failed bearing or...