Oil analysis is widely recognized as one of the most potent tools in precision lubrication and reliability engineering. Yet, despite decades of industry experience, many organizations unknowingly undermine their effectiveness before the first sample is even taken. A...

Lubricant Analysis

How Strategic Oil Analysis Reduces Risk and Extends Equipment Life

The reliability and availability of industrial assets are critical factors for the competitiveness of modern organizations. In this context, maintenance has evolved from a predominantly corrective model to preventive, predictive, and more recently, proactive...

Standby Generators Need Proactive Fluid Analysis to Stay Reliable

In industrial and manufacturing facilities, lubrication and condition-monitoring programs focus on equipment that runs every day, such as compressors, gearboxes, pumps, turbines, and hydraulic systems that keep production moving. These critical assets are often...

How to Interpret RPVOT Regions for Better Lubricant Decisions

It is very likely that you have encountered the RPVOT (Rotating Pressure Vessel Oxidation Test), a laboratory test developed in the 1960s and later standardized by ASTM D2272. It measures the antioxidant stability of lubricating oils by accelerating oxidation in a...

From Oil Samples to Algorithms: Leveraging AI and Automations

Maintenance teams are entering a new era, one where data-driven insights enable automation and transform how equipment health is monitored and maintained. For years, the industry has been moving from preventive maintenance to predictive maintenance, but what’s next?...

How EGR Failures Destroy Engines – and How Oil Analysis Detects Them

The EGR (Exhaust Gas Recirculation) system recirculates a fraction of the exhaust gases into the intake manifold to lower combustion temperature, reduce NOx emissions, and, in some cases, improve fuel consumption in both diesel and gasoline engines. This recirculation...

Why Drain-Based Oil Sampling Breaks Trends, Decisions, and Quality

Oil analysis is one of the most potent tools in proactive maintenance and asset management. However, its effectiveness depends fundamentally on one critical factor: the quality of the collected sample. Even today, many professionals still take samples directly from...

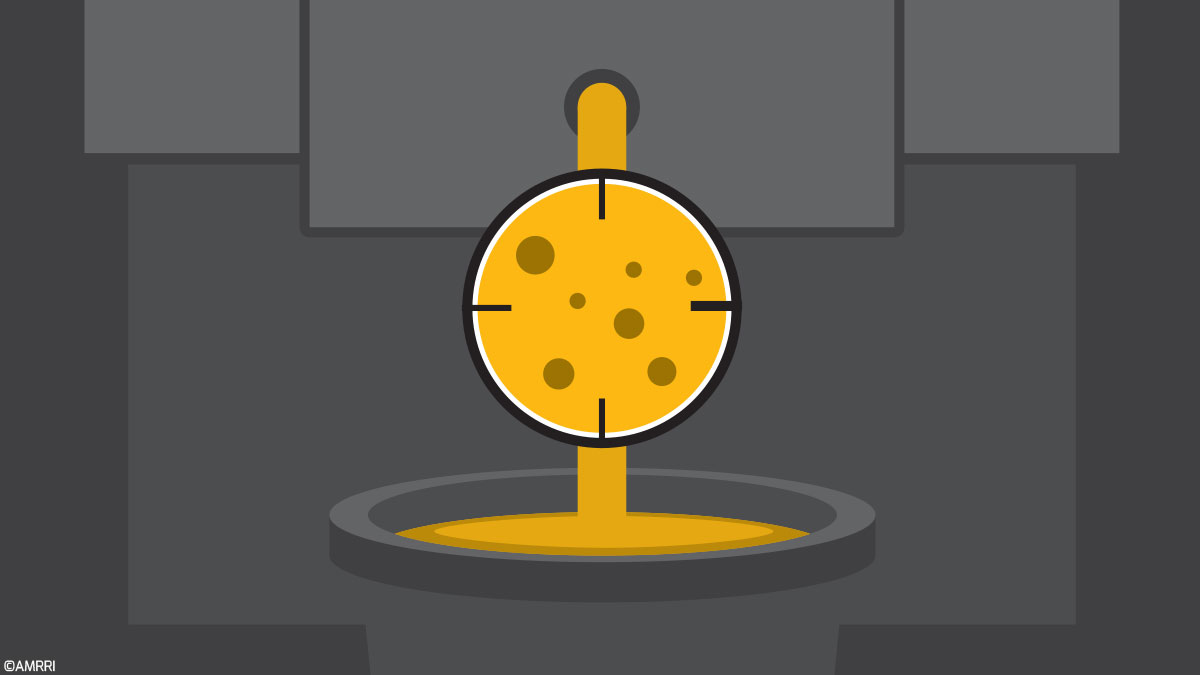

Ferrous Density and Particle Counting: Building a Balanced Strategy

I had a laboratory manager, over twenty years ago, complain to me that he wished I would stop pushing particle counting, as he was getting annoyed by clients asking for it after my courses. In his view, particle counting was necessary primarily for hydraulic oils and...

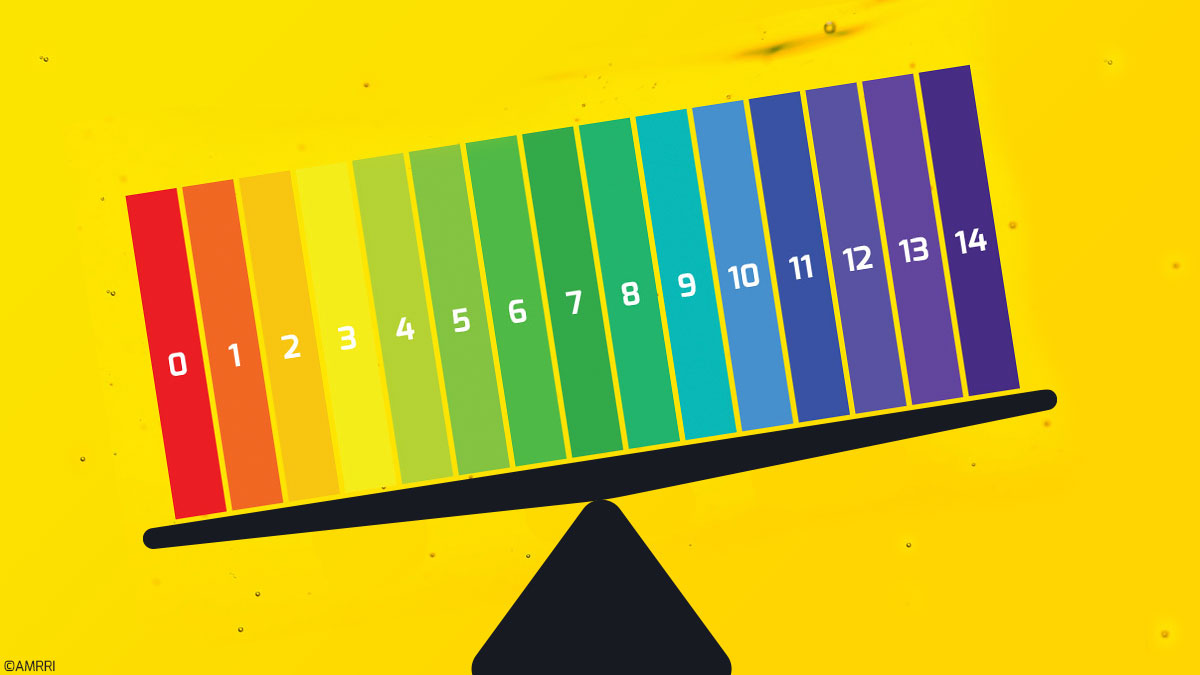

How Acid Number and Base Number Reveal the True Health of Diesel Oils

Lubrication analysis plays a vital role in predictive and preventive maintenance for diesel engines. Among the most informative tests available are Acid Number (AN) and Base Number (BN), two complementary measurements that provide insight into oil health, additive...

How to Extend Oil Drain Intervals Safely Using Condition Monitoring

What is Condition Monitoring and Why Is It Important? In this age of artificial Intelligence and sensors that pop on and off, we often forget about the basics and where things all started. Condition monitoring began as a way to detect anomalies in our equipment using...