Ugly. Torturous. Scourge. Devastating. Catastrophic. Insidious. These are just a few of the words used in papers and presentations to describe the effects of water in oil. You get the picture. For good reason, water has been called the second most destructive...

Contamination Control

How to Protect Pumps and Gearboxes by Removing Water from Oil

Why Water in Oil Is So Dangerous From an early age, we learn that oil and water do not mix. While that is not exactly true in the world of lubrication, it is true to say that any degree of water in a lubricant can cause irreparable harm to both the lubricated...

Lubricant Foaming: How to Diagnose and Eliminate the Problem

What is Lubricant Foaming? Lubricant foaming is a deceptively complex phenomenon often dismissed as mere surface bubbles on top of oil reservoirs. Yet seasoned lubrication engineers and tribologists understand the critical threat foaming poses to lubricant performance...

How to Turn Gearbox Contamination Control into a Competitive Advantage

At any given point, the overall contamination in a gearbox is BIG! Remember that contamination ingression is the overall amount of contaminant in the oil with: B – Built-in contamination from the unit's manufacture. I – Ingested is the “sucked in” contamination during...

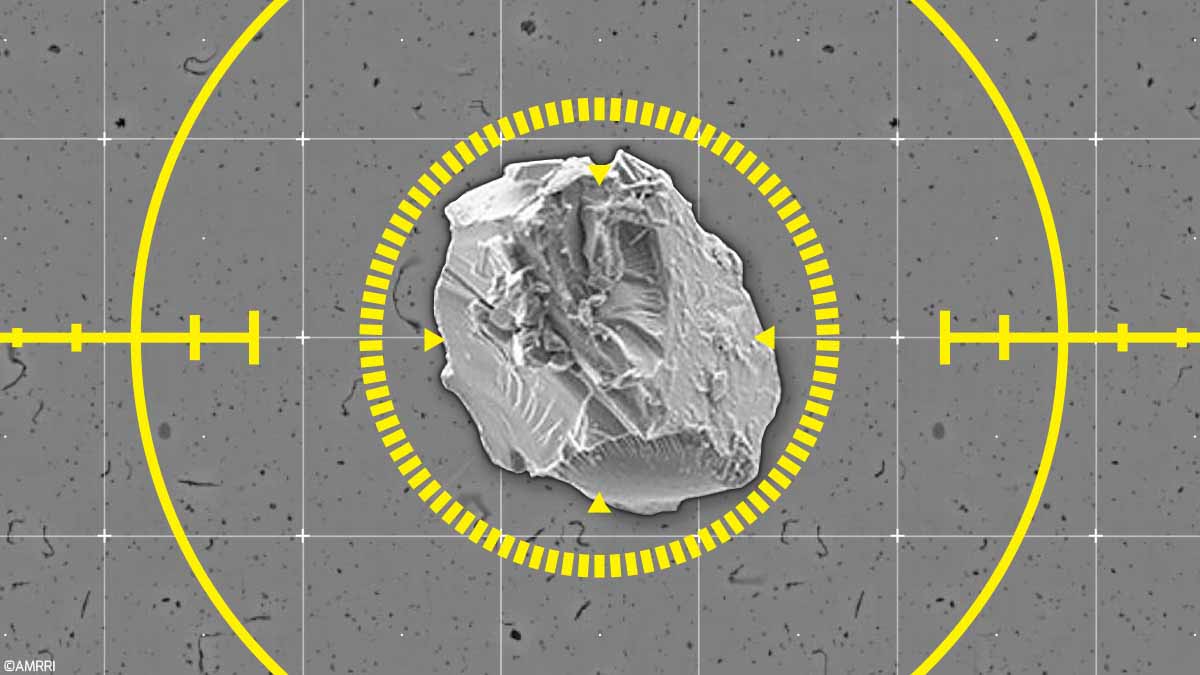

Contamination Control: Improve Cleanliness, Prevent Failures with Particle Count

Contamination within lubricants circulating through equipment can range from air, water, or, the most damaging, particles. The most common cause of equipment failure is particle contamination in the lubricant, and, specifically, 80% of hydraulic system failures can be...

Seal the Deal: Practical Steps to Combat Contamination in Pumps

What Causes Wear? Contamination has frequently been identified as one of the major causes of premature wear on rotating machines. If all other root causes, such as the alignment, balance, and mounting integrity, have been checked, then the other major influences are...

How Hidden Contaminants Lead to Machine Failures and Downtime

If a machine is to provide service life past its warranty stage, its designer must envision and consider all operating conditions under which it will operate in the field. For example, to mitigate the effects of severe and semi-severe conditions, the design must be...

How to Calculate the Beta Ratio of Your Oil Filter

Calculating the beta rating for an oil filter involves understanding how effective the filter is at removing particles of a certain size from a fluid. The beta rating is a standard measure used in filtration to quantify the filter's efficiency, specifically its...

Air in Oil Contamination: Causes, Effects, and Solutions

Many people emphasize the impact of particle and moisture contamination on equipment reliability, but few consider how air might affect their equipment. While usually benign, excessive air entrainment can lead to many issues, including rust, cavitation, oil leakage,...

How Efficient is Your Oil Filter?

It has long been known that contamination is the leading cause of failure in rotating and reciprocating equipment. For this reason, most circulating oil systems contain some form of filtration on the supply line and occasionally, in the case of hydraulics, on the...