Challenges in Grease Selection Without Full Bearing Specifications Bearing manufacturers have provided a significant amount of detailed advice for lubricant selection, application, and replenishment. Formulas used by the machine designers incorporate details that are...

Bearings

How Grease Exudation and Hardening Damage Bearings and Raise Costs

During inspection and maintenance activities, it is common to identify possible sources of lubrication-related failures, and one of the most recurrent is the constant leakage of oil in grease-lubricated bearings. This problem, often underestimated, can cause dryness...

How to Extend Bearing Life with the Right Lubricant Choice

All machines with moving parts have bearings of some type. The bearings may be as simple as flat surfaces working against other flat surfaces, such as the slideway in a machine tool, or they may have sophisticated geometries like a ball screw. Plain and element...

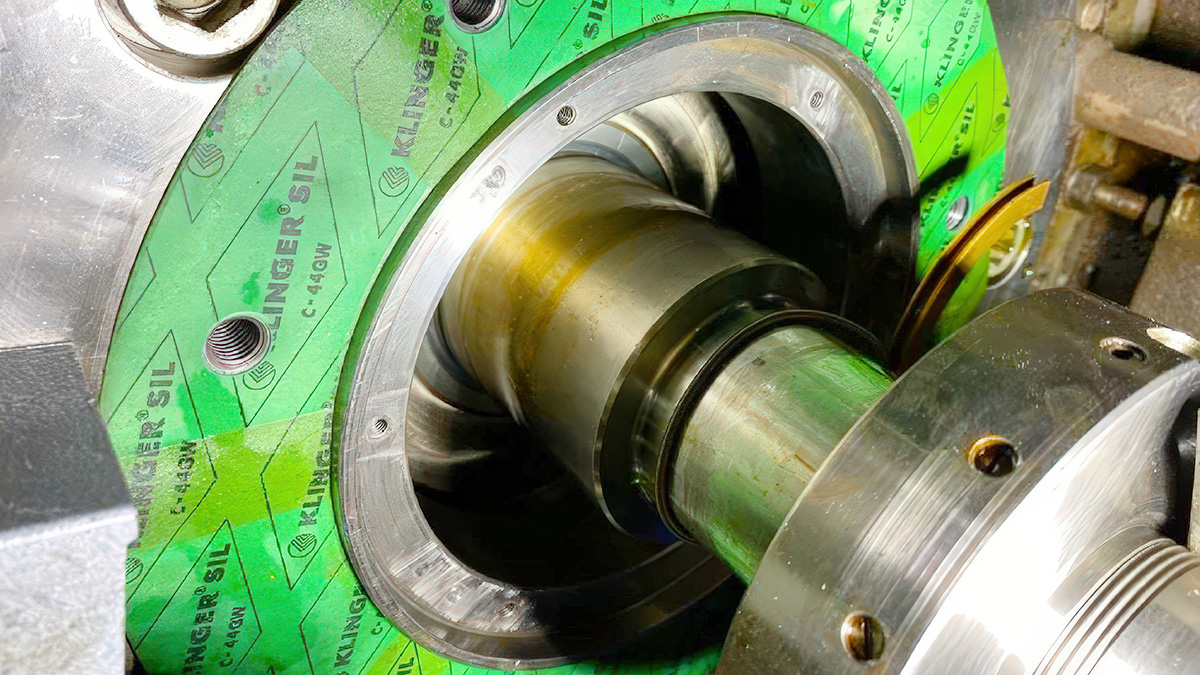

Dissolving Downtime: How Solubility Enhancers Prevent Refinery Shutdowns

Whether we realize this or not, oil refineries are critical in our everyday lives. They convert crude products into diesel, gasoline, LPG, and plastics. The equipment in this plant must withstand very high temperatures, sometimes over 500°C (in the distillation unit)....

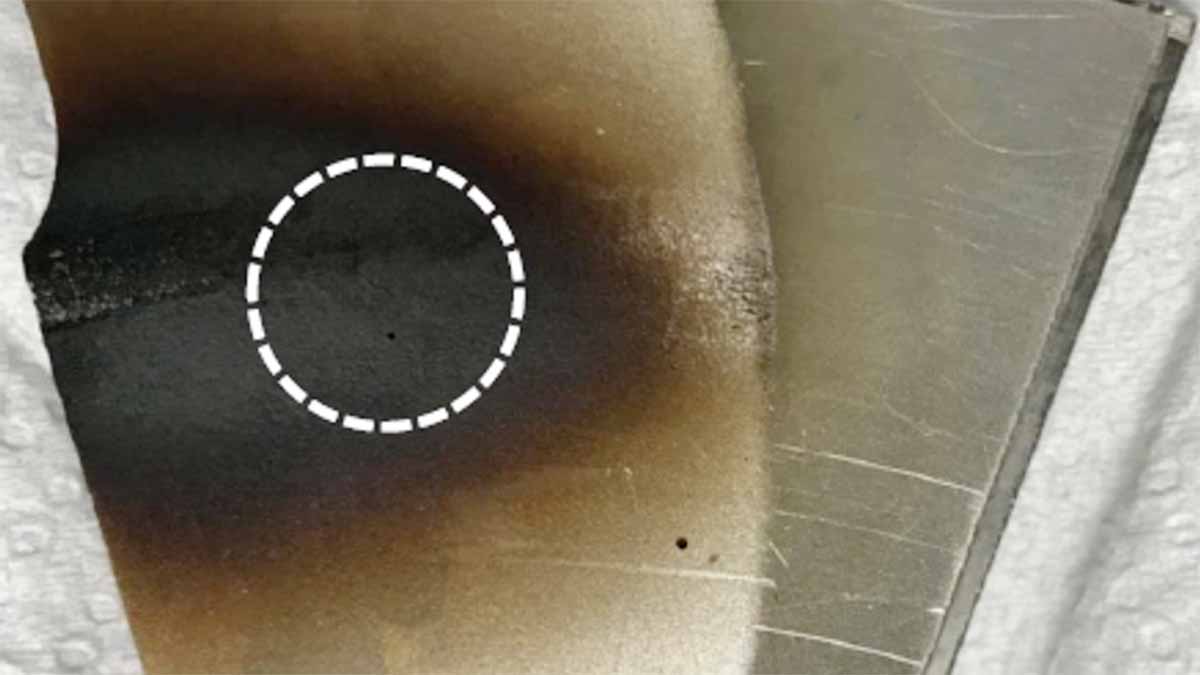

When Bearings Fail: A Fire Pump’s Hard Lesson in Reliability

In a Middle Eastern refinery, a newly commissioned fire water pump, crucial for emergency services, experienced repeated high temperatures at the non-drive end (NDE) bearing during periodic test runs. Over time, these temperature spikes eventually led to a premature...

Why Bearings Fail: Lubrication Mistakes Cause 70% of Breakdowns

It's very much a lubrication issue. To prevent two metal surfaces from welding due to excess friction, keep them apart when expected to interact. A suitable film of lubricating oil accomplishes that. Some 50 years ago, MIT Mechanical Engineering Professor Emeritus...

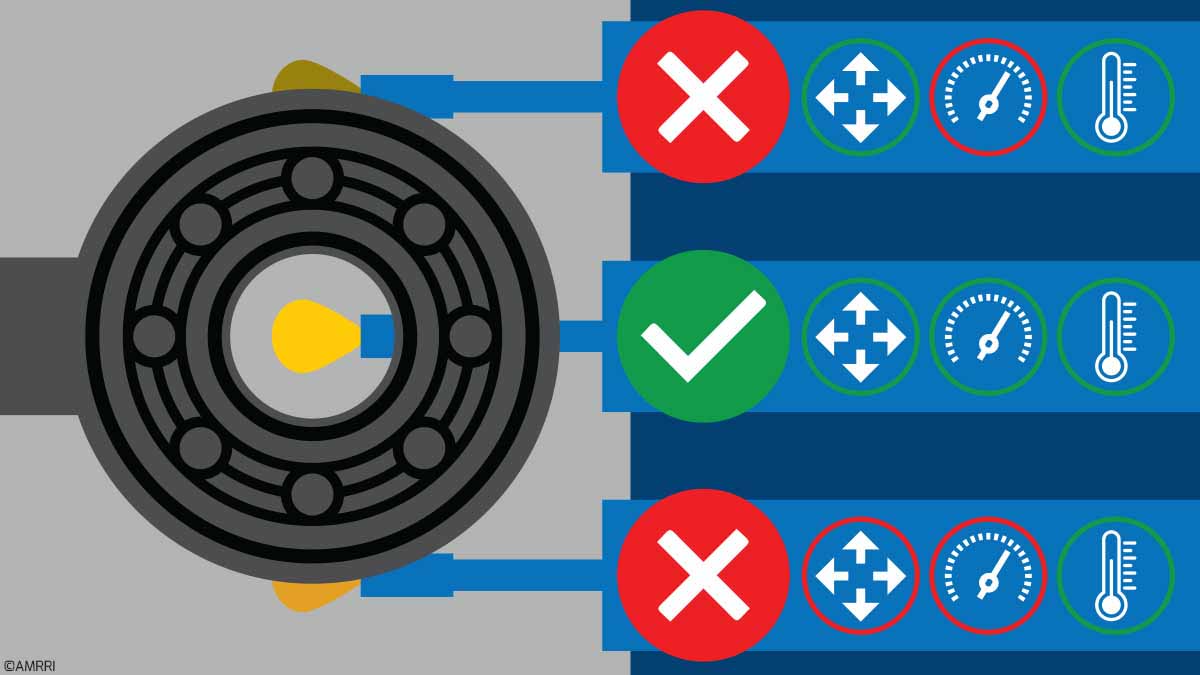

Why Grease Analysis is Essential for Predictive Maintenance Success

Grease has been used since ancient times, and new technologies and equipment design require us to improve our understanding and perception of it. These advancements enable those working with grease to recognize better its impact, effective properties, and the proper...

Mastering the Grease Gun: Essential Practices for Effective Lubrication

Grease guns seem simple enough. But how well do you know yours? Do you know how to correctly cartridge and bulk load your gun? Do you know how to expel trapped air from it? Do you know its shot size in cc or cu in (e.g., in cubic centimeters or cubic inches)? Do you...

Mastering the 5 Stages of Bearing Life for Improved Reliability

All bearings are destined to fail eventually. While ineffective lubrication practices are arguably the greatest contributing factor in such failures, the root cause(s) are rarely investigated due to production and maintenance turnaround demands. It's through...

Varnish Deposits in Bearings: Causes, Consequences, and Cures

Varnish is characterized as a deposit originating from the degradation of lubricating oils. These degradation byproducts are predominantly polar compounds, exhibiting inherent instability within the non-polar phase of the lubricating oil. Due to this chemical...