When the lube room resembles a crime scene - chaotic storage, unlabeled containers, questionable handling tools, inconsistent transfer practices - it becomes a hidden driver of accelerated wear, additive depletion, ingress-driven contamination, and component life...

Articles

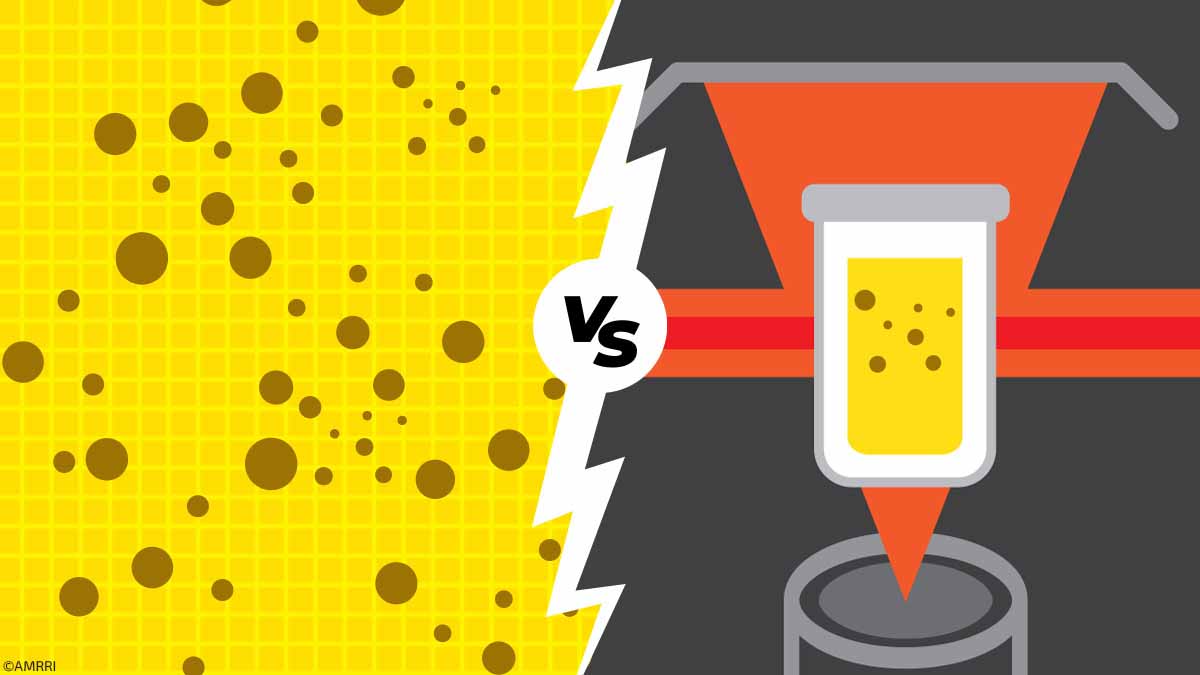

Why Drain-Based Oil Sampling Breaks Trends, Decisions, and Quality

Oil analysis is one of the most potent tools in proactive maintenance and asset management. However, its effectiveness depends fundamentally on one critical factor: the quality of the collected sample. Even today, many professionals still take samples directly from...

Maintenance & Reliability: Where You Fit on the Industrial Tribology Map

When I go into industrial plants and tell the Lubrication Team, aka, oilers and greasers, that they are Tribologists, I usually get a look of confusion on how they would fit in. When you first think of Tribology, your thoughts may immediately go to all the great PhD...

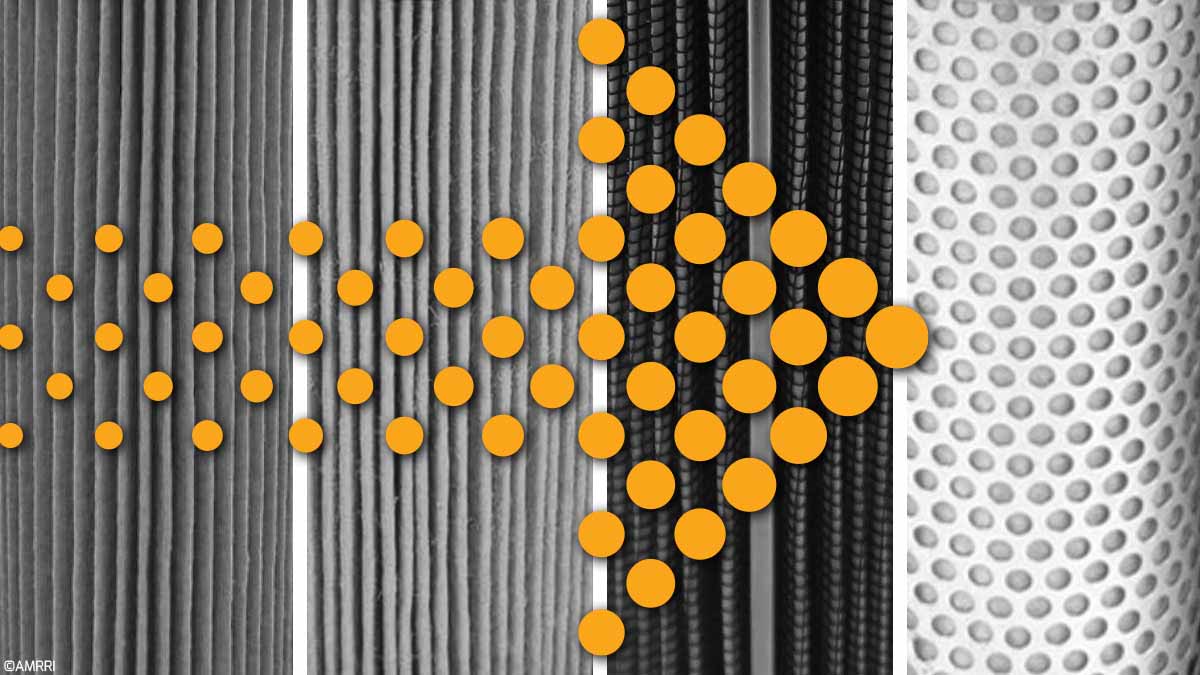

Ferrous Density and Particle Counting: Building a Balanced Strategy

I had a laboratory manager, over twenty years ago, complain to me that he wished I would stop pushing particle counting, as he was getting annoyed by clients asking for it after my courses. In his view, particle counting was necessary primarily for hydraulic oils and...

How to Pick Between Lubrication, Oil Analysis, and Tribology Certifications

"I want to obtain a certification in the area of..." is often one of the goals set by maintenance personnel, especially those working in predictive maintenance. One of the certifications in the predictive area that has seen significant growth is the lubrication...

How Fine Is Too Fine in Oil Filtration Systems?

As with many things in lubrication, sometimes too much is as bad as too little. This is certainly the case with filtration. How Fine Is Too Fine for Your Oil Filter? To answer that, we need to look at several factors. First, let’s dispel a few myths about fine...

Lubricant Varnish: How to Detect, Prevent and Fight this Silent Enemy

Varnish formation is one of the most critical and often overlooked challenges faced by industrial lubrication systems, especially in high-performance applications such as steam turbines, gas turbines, compressors, and precision hydraulic systems. Even when invisible...

Root Causes of Electrostatic Spark Discharge in Modern Lubrication Systems

Understanding Electrostatic Spark Discharge and Its Impact on Lubrication Systems Electrostatic Spark Discharge typically occurs when static is built up in an oil at a molecular level, causing it to discharge in the system and create free radicals, which increase the...

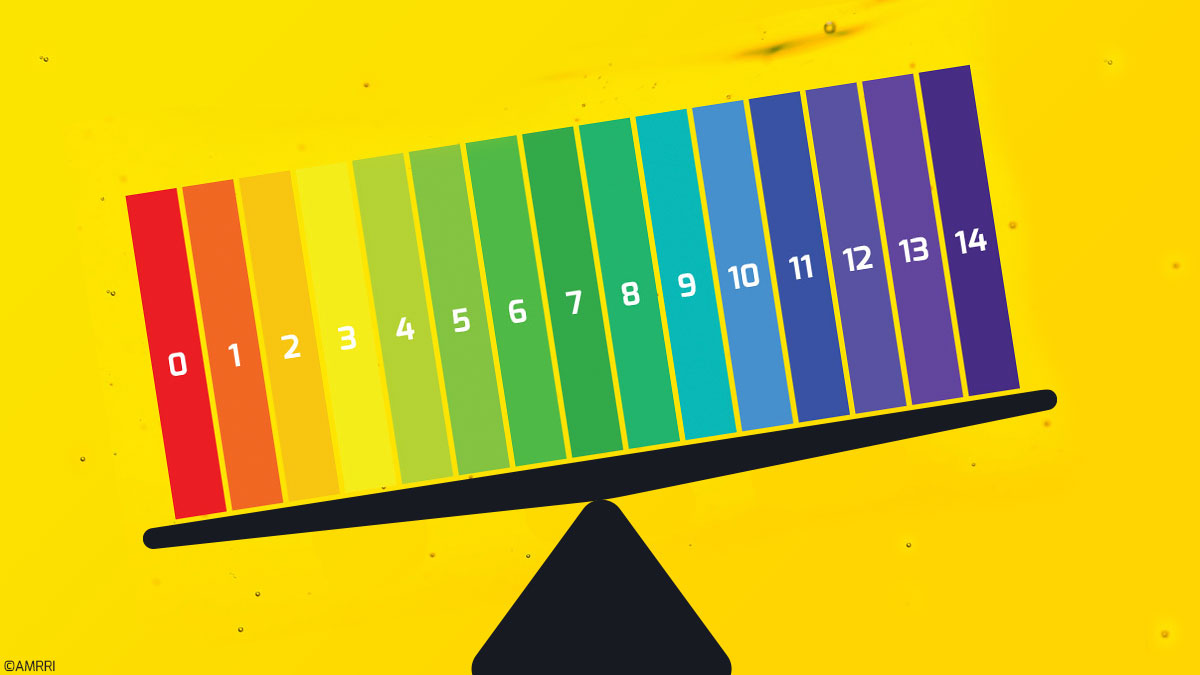

How Acid Number and Base Number Reveal the True Health of Diesel Oils

Lubrication analysis plays a vital role in predictive and preventive maintenance for diesel engines. Among the most informative tests available are Acid Number (AN) and Base Number (BN), two complementary measurements that provide insight into oil health, additive...

The Multi-Functional Role of Modern Lubricants in Machine Reliability

I was once asked, “Why are lubricants so different? Why can’t we simply buy a ‘one fits all’ oil and grease?” I explained that the old farmers' axiom, “Oil is oil, any oil will do,” may have had some merit 100 years ago, but it doesn’t now. In today’s world of...