Look at the product data sheet for any full synthetic industrial lubricating oil, and you will likely discover that the base oil is a polyalphaolefin (PAO).

These lubricants have become the backbone of high-performance lubricants for the better part of 50 years, with new metallocene variants continuing to spur ever higher performance standards. However, half a century of technical innovation has brought some exciting alternatives that could soon make their way to market.

The Significance of PAOs in the Industry

PAOs have an exciting history as synthetic lubricants. Their development can be traced back to the research on the polymerization of olefins in the late 1930s. Initially, these studies focused on creating polymers and plastics, but like many molecules from the petrochemical world, their potential for applications in lubricants was soon recognized.

In the 1940s and 1950s, the process of oligomerization was developed. This process, critical in producing PAOs, involves the polymerization of alpha-olefins to create oligomers, short-chain polymers that serve as the building blocks for PAOs.

The real breakthrough in PAO development came in the 1960s. Researchers found that carefully controlling the oligomerization process could produce lubricants with excellent thermal and oxidative stability, high viscosity index, and low pour points. These characteristics made PAOs ideal for extreme temperatures and applications requiring stable, long-lasting lubrication.

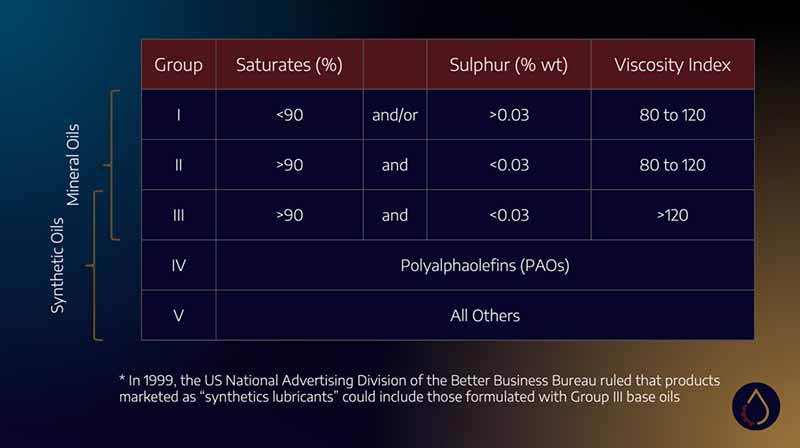

The API base stock classifications

Ever since, this molecule has been onward and upward—the significance of its use is even enshrined in the API base stock groups, where PAOs are the only synthetic base oil to receive their own category (Group IV).

This vaunted place owes much to the automotive industry, where high viscosity index is a prized property that allows for both high film strength at operating temperatures and good cold start-up performance.

The Performance of PAO Industrial Lubricants

Beyond automotive, many performance features make PAOs ideal for industrial lubricating oils. Its oxidative stability and response to antioxidant additives enable extended oil drains, even with high operating temperatures.

Its demulsibility helps water separate readily in reservoirs, allowing the volume to be drained readily. High viscosity index results in good flow properties and high hydraulic efficiency.

Its narrow molecular weights give them low volatility and flash point. And it’s combination of high film strength and low traction properties enables the use of synthetics when energy efficiencies are required.

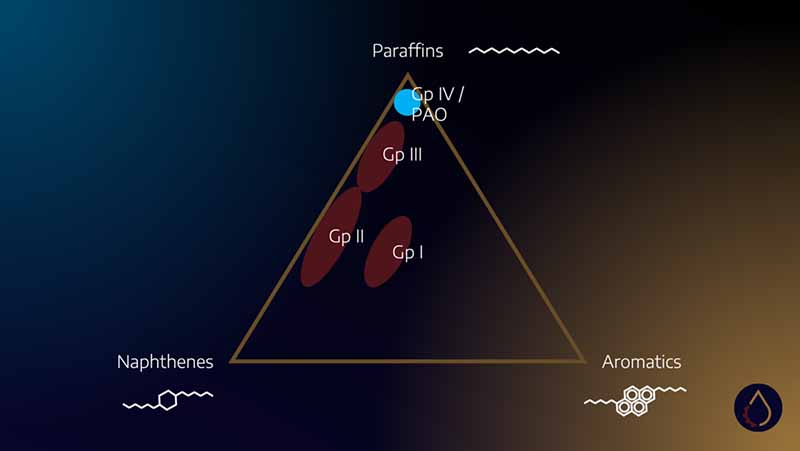

Typical molecular content of the API base stock groups

Newer developments have seen the rise of metallocene catalysts creating higher-performance PAOs (sometimes called mPAOs to distinguish them from their conventional cousins).

These molecules offer even higher Vis, better demulsibility, and improved oxidative stability and are enabling technologies like the next generation of wind turbine gear oils, which are often warrantied for 10-year oil drains.

But all technologies have an Achilles Heel, and the same low polarity that gives PAOs their water separability and foam performance introduces challenges such as additive solubility and seal swell. In an era where bio-based and bio-degradable lubricants are becoming more popular, PAOs offer neither feature.

Emerging Alternatives

As the lubricants industry evolves, alternative base oils emerge as viable alternatives to traditional polyalphaolefins (PAOs). Driven by technological advancements and an increasing focus on sustainability, new molecules like Synnova and ethylene-propylene oligomers have emerged.

In both cases, the molecular structure of these novel base oils bears striking similarities to PAOs, and that is reflected in their performance.

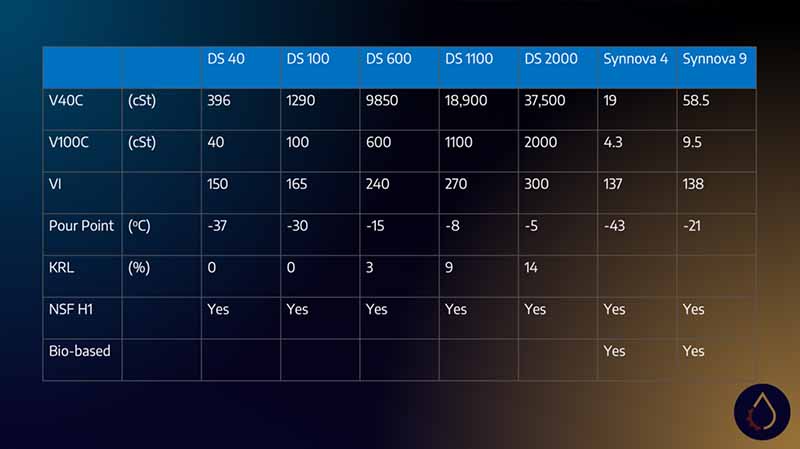

Synnova (currently made by Novvi) is derived from renewable feedstocks. Formerly made from sugarcane derivatives, Synnova base oil production is carbon-negative, and the low molecular-weight variants are 100% bio-based and 70% biodegradable by OECD 301b. Its performance characteristics closely mirror PAOs, although the pour point is slightly higher.

Synnova offers the possibility of creating bio-lubricants without the use of esters. For many years, esters and PAGs have been the only pathway to the creation of bio-based lubricants, with esters generally preferred due to the incompatibility concerns using PAGs.

However, ester instability in the presence of water has always been a challenge when using them in applications. When formulated with the right co-bases and additives, Synnova could be a fluid that overcomes these challenges.

Typical properties of D.Synol (an EPO) and Synnova

EPOs (ethylene-propylene oligomers) are another base oil class that warrants attention. The molecules produced by companies such as Mitsui and Daelim look like a hybrid of PAOs and VI improvers. These polymers exhibit exceptional shear stability, film strength, and viscosity control, making them suitable for demanding operating conditions.

As a substitute for heavy PAOs, VI improvers, and thickeners like polybutenes, EPOs offer interesting formulation flexibility as they can replace multiple functions. With slightly better solubility performance than PAOs, they can also help reduce the seal swell agents often needed in PAO lubricants.

The likelihood that any of these contenders entirely displace PAOs is virtually zero. PAOs command a level of scale and formulation history that makes them one of the industry’s backbones. However, alternative base oils such as Synnova and EPO polymers offer promising pathways with the potential to redefine industry norms and reshape the competitive landscape.