Like other condition monitoring techniques, oil analysis is vital in monitoring equipment health and maintaining performance. It aims to detect underlying root causes of failure and early-stage potential failures before they cause significant damage.

Oil sampling is an essential process in oil analysis. It consists of drawing a small amount of oil from the equipment, analyzing it to assess its condition, and looking for early signs of wear and contamination.

Why Draw Oil Samples?

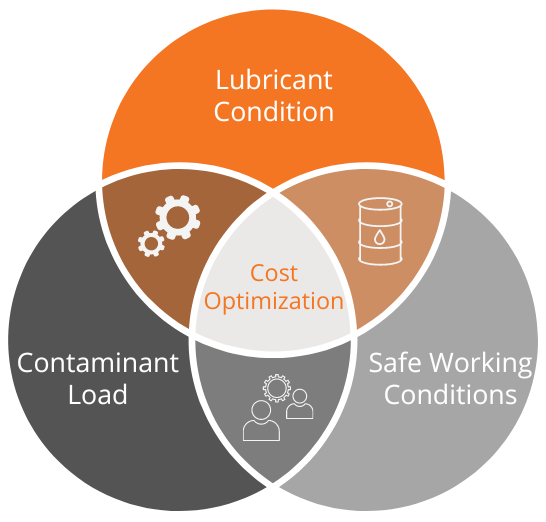

Oil analysis helps us monitor the oil condition and the current operating state of the equipment in which the oil is used. Accordingly, it helps optimize costs and productivity and helps ensure safe working conditions.

There are several desirable outcomes of a successful oil analysis program, including:

Lubricant Condition Monitoring

Over time, oil can break down, become contaminated, and its properties can degrade. Lubricant Condition Monitoring deals with the assessment of the chemical, physical and performance properties of the oil.

Testing and verifying these properties can assess the oil’s remaining useful life and determine when it has become degraded and not serviceable anymore.

Checking the condition of the oil reveals meaningful information. It will tell us, for example, if the oil’s viscosity changed due to contamination, oxidation, thermal degradation, or other chemical reactions.

Additionally, it informs about depleted or impaired additives and the damage of base oil by oxidation, hydrolysis, or thermal degradation.

Equipment Health Monitoring

Maintenance technicians can identify needed corrective actions early on by analyzing the oil for developing evidence of abnormal wear, oil properties degradation, and contamination, such as filter change, oil filtration, oil dehydration, or even oil replacement.

This helps prevent significant damage and costly repairs or replacements. Thus oil sampling can help improve equipment performance and extend the overall usable life of lubricant and equipment.

Oil analysis helps reduce sudden in-service failures and is essential even before equipment commissioning.

Oil analysis can confirm if new equipment has a manufacturing defect and has been properly commissioned.

Additionally, oil analysis can help establish if a machine has been adequately repaired or rebuilt. It can also help identify lubricant-related sabotage activities.

Lubricant Pollution Measurement

Given that the lubricant is a carrier of information about machine and lubricant health, it is also an effective carrier of information about the pollution state of the machine.

Moreover, oil analysis can reveal the presence of undesirable contaminants, either liquid or solid (cross-contamination with other fluids or lubricants, fuel, water, process fluid, coolant, soot, dirt, rust, etc.). Proper corrective actions to address external contaminants identified in analysis ensure that goal-driven contamination targets are maintained.

Cost Optimization

Many potential problems can be identified thanks to oil analysis before they become severe enough to cause equipment failure or downtime. Equipment is maintained in good condition, unplanned downtime is minimized, and productivity is steady.

By assessing the combustion quality and identifying faults that lead to engine inefficiency and excessive fuel consumption, like a leaky fuel injector, oil analysis can help machine owners lower fuel consumption.

Additionally, oil analysis can help improve the quality of equipment and lubrication maintenance decisions. Drain intervals can be extended by establishing condition-based oil changes and maintenance actions, leading to reduced oil consumption. Unnecessary maintenance, such as time-dependent component changes (oil, filter, and separator replacements), can be reduced.

Safe Working Conditions

Oil analysis is an excellent tool for maintaining and improving safe working conditions. Regular oil analysis helps ensure that equipment functions properly and safely, reducing the risk of accidents and injuries to operators and workers.

Contaminated or degraded oil can lead to increased friction, wear, and heat, which can cause machinery malfunction or even a safety hazard to workers and operators.

Regarding environmental compliance, if you use lubricants, you must dispose of them when changed. By reducing oil changes, you reduce your environmental impact.

What Equipment Should Be Sampled?

When selecting equipment to be monitored by oil analysis, consider the following criteria:

Equipment Criticality

Overall Lubricant Criticality (OLC) is one of many existing methods and approaches to determine equipment criticality. What is specific with OLC is that it assesses the criticality of equipment in the context of lubrication.

It defines the overall importance of lubricant health influenced by both the probability and consequences of lubricant and machine failure. OLC involves the following factors:

- Machine Criticality Factor (MCF): This factor is associated with the consequences of machine failure, combining mission criticality and repair costs.

- Failure Occurrence Factor (FOF): Corresponds to the probability of failure. This probability is highly influenced by maintenance and lubrication practices.

- Lubricant Criticality Factor (LCF): Defines the economic consequences of lubricant failure. The cost of the lubricant affects the LCF, the cost of the downtime to change the lubricant, the flushing cost, the system disturbance cost, etc.

- Degradation Occurrence Factor (DOF): Defines the probability of lubricant failure. Influencing sub-factors include lubricant robustness, operating temperature, contaminants and other exposures, lubricant makeup rate, etc.

How Often Should You Sample Oil?

Once the equipment is selected to be monitored by oil analysis, it is time to define how often it should be sampled. This is not an easy task as oil sampling frequency can be a complex process that requires careful consideration of several factors, such as Equipment Criticality, Equipment Type, Oil Type, Cleanliness Target Tightness, Historical Machine Failures, Failure Modes, Fluid Environment Severity, and Operating Conditions.

Sampling less frequently can risk missing a machine or lubricant failure. Sampling more frequently can waste time and money. For example, machines that operate in harsh conditions or are subject to high loads may require more frequent sampling.

Machines that use synthetic oils may require less frequent sampling as they are more resistant to oxidation and contamination. The more we know about the equipment, the easier it is to determine the optimum sampling frequency.

On the other hand, many general advisory recommendations can be found. Experts in the field can also be consulted to determine the appropriate sampling frequency based on their experience with similar equipment. Additionally, OEM and oil suppliers can provide valuable advice.

The frequency of oil changes is determined so that the oil remains serviceable and can fulfill its technical functions inside the equipment between two complete oil changes. Be sure to take a sample well before the end of this period to detect early signs of wear, oil degradation, and contamination.

When implementing an oil analysis program with no OEM recommendations for oil sampling frequency, consider sampling it at 2/3 of the oil change frequency (see figure below). The frequency can be adjusted after enough data has been collected.

Who Should Draw Oil Samples?

The International Council for Machinery Lubrication (ICML) has detailed in ICML 55.1 the required skills and qualifications for all personnel involved in lubrication management.

For lubrication technicians designated to execute routine tasks as defined in work procedures and job descriptions (task-based training), the body of knowledge set forth is Machinery Lubrication Technician (MLT-I) or equivalent. Oil samples should be drawn by qualified technicians who:

- Understand what a representative sample is.

- Are familiar with the equipment being sampled.

- Have mastered oil sampling procedures.

In conclusion, every oil sampling strategy cannot apply to all equipment and applications. When an oil sampling program is well designed and implemented, the equipment life can be extended, the risk of costly breakdowns can be reduced, and safe working conditions are ensured.

However, it is crucial to consider adjusting the oil sampling frequency over time as a lubricant, operating conditions, and other factors change to ensure that it is still convenient for the context where it was initially established.

Additionally, a cost-benefit analysis should be considered. More frequent sampling may provide more data and earlier identification of impending failures, but on the other hand, it involves more costs. Finding the balance between adequate data and cost-effectiveness is crucial.