Ferrous debris refers to small metallic particles, primarily iron, found in lubricating oils and greases caused by mechanical wear and damage to metal components. Early detection of this debris is critical, as it can indicate system wear before major damage has time to occur.

Fluid analysis can measure this ferrous debris, so you can catch it early and address the root issue. Are your bearings or gears experiencing fatigue? Is your lubricant sufficient, or is it degraded? Is there an ingress of dirt, water, or other contaminants causing wear?

From Metal to Metrics: Measuring Ferrous Debris

Determining the amount of ferrous debris detected in a sample can narrow down what is wearing down to cause these particles and give insights into repairs. Measuring the amount of ferrous debris in an oil sample can be challenging, and analyzing with ICP-OES (Inductively Coupled Plasma – Optical Emission Spectrometry) is limited to particles lower than ~5–10 microns (µm) in diameter.

There are two main methods for measuring larger ferrous debris particles, which can give more insights into particle size: PQ™ (Particle Quantifier) and FerroQ™.

When discussing the differences in measurement and getting a bit technical about the instrument itself, both PQ™ and FerroQ™ measure the magnetic interference of a magnetic field caused by ferrous particles. The difference is that for PQ™, the magnetic field is generated under the oil sample in the bottle (which amounts to only the bottom centimeter or so).

With the FerroQ™ method, the magnetic field surrounds the oil sample as the sample is placed inside the field, analyzing the entire sample, enabling better and more accurate analysis.

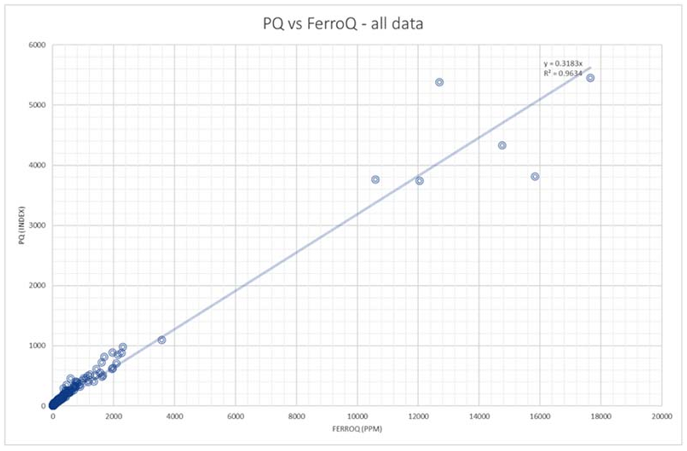

Because of this difference in fields used for measurement, the PQ™ system has limitations. When comparing the results, the PQ™ index displayed a skew, most likely due to PQ™ not analyzing the entire sample, as seen in the graph below.

Better Data Starts Here: Say Hello to FerroQ

As a fluid analysis laboratory, we’re continuously looking to improve our analysis services and help customers make data-driven maintenance decisions. After weighing different test methods of determining the amount of ferrous debris in an oil or grease sample, POLARIS Laboratories® is making the official switch over to reporting results with FerroQ™.

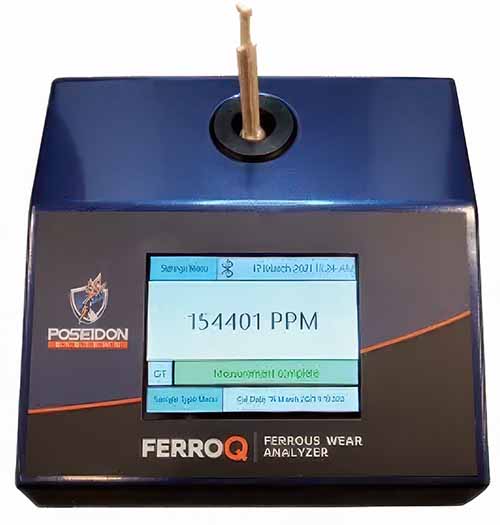

The Poseidon FerroQ™ instrument represents a better technique and allows us to provide fluid analysis customers with more precise analysis of the test results. Because the FerroQ™ instrument reports its results in ppm, instead of an Index like PQ™, results are quantifiable, NIST (National Institute of Standards and Technology) traceable, and more adequately meet quality standards.

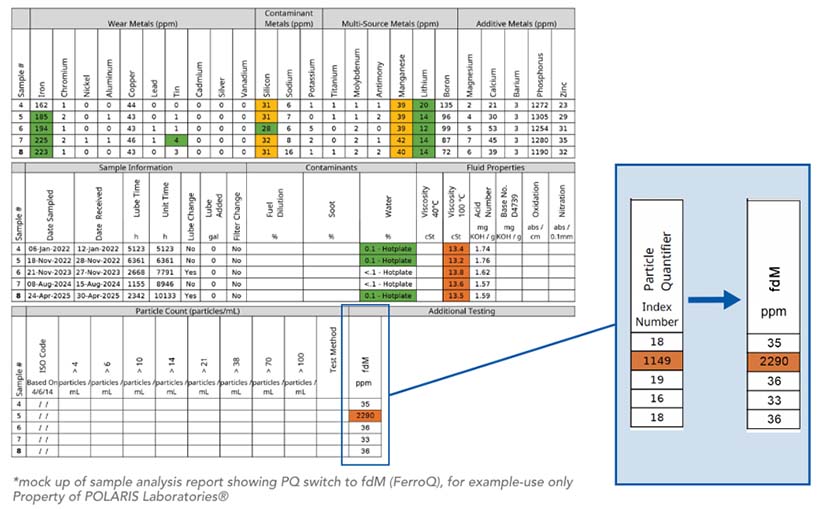

When POLARIS Laboratories® implements this switch in the coming months, instead of reporting results on the PQ™ Index, test results will be displayed in ppm on the sample report. An example of reported FerroQ™ results on a sample report is below.

Essentially, when comparing reporting based on PQ™ Index vs. ppm, FerroQ™ test results are about double PQ™.

New Insights Ahead: Analyzing Samples with FerroQ™

Switching from PQ™ to FerroQ™ marks a significant advancement in how ferrous debris is measured and reported in fluid analysis. With FerroQ™, we’re not just improving measurement precision, we’re providing more accurate analysis that can identify early signs of wear to prevent unplanned downtime.

For more insights into quantifying ferrous debris, methods, reporting, and analysis referenced in this article, read Assessing Spectroscopic Methods to Analyze Particles: PQ vs. FerroQ published February 2024.