If your maintenance strategy includes getting more life out of your lubricants while ensuring equipment reliability, then optimizing, not merely extending, your oil drain intervals should be your focus.

The term “optimize“ is preferred over “extend“ when discussing drain intervals. While it may be possible to extend drain intervals, doing so without proper insights and data can compromise lubricant health and equipment performance and shorten equipment life.

Define Your Objective

To safely optimize your oil drains and get more out of the lubricants, start by defining what success looks like whether it’s increasing runtime hours, mileage, or reducing lubricant consumption without increasing risk.

Before changing drain intervals, rule out contamination – filtration and clean oil often determine success more than the lubricant itself.

If you’ve tried to optimize intervals in the past and efforts fell short, you may want to investigate environmental contaminants like dirt, rather than the lubricant’s performance. In this scenario, to safely optimize intervals, you will need to look at your contamination control practices. Are you using the correct filter? Is there better filtration available? Are you starting with clean oil? Before modifying drain intervals, evaluate these contamination control strategies to ensure they aren’t the limiting factor.

Use Oil Analysis to Guide Decisions

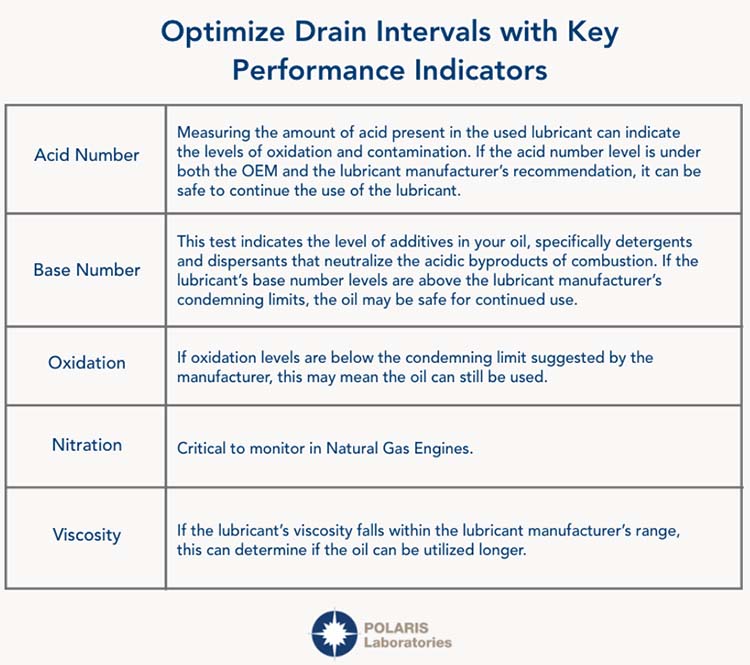

Oil analysis laboratories can help you achieve your goal of optimizing drain intervals through established Key Performance Indicators (KPI’s) measured through testing.

Results from laboratory testing can indicate the amount and levels of acid, oxidation, nitration, and the oil’s viscosity. These parameters are benchmarked against Original Equipment Manufacturer (OEM) and lubricant manufacturer guidelines. As long as they fall within acceptable limits and trending supports stability, it may be safe to extend lubricant use.

Real-World Scenarios

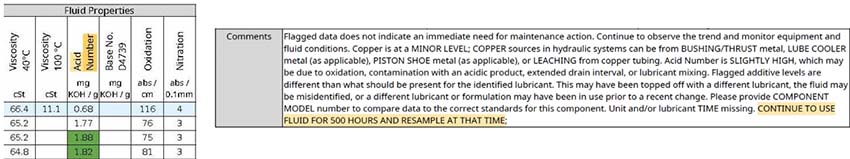

In one scenario, a customer in the dredging industry had a goal to optimize drains for a hydraulic power unit. Oil analysis flagged results for Acid Number at the lowest severity, 1 (Figure 1). After a few trending samples of low-severity results, the laboratory confirmed the customer was able to extend the drain interval by 500 additional hours.

Figure 1

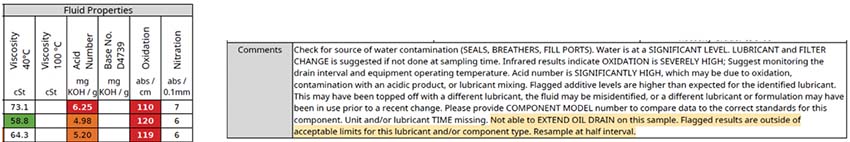

On the other hand, oil analysis can indicate when it is not safe to extend drains, too. In this example, a mining customer received a sample report where both Base Number and Oxidation were flagged high on the severity scale (Figure 2) and outside of the acceptable limits; therefore, it is not safe or recommended to continue to use the lubricant.

Lean on Your Laboratory

All in all, it is possible to optimize lubricant drain intervals to get more use out of the lubricants on hand. Work closely with your oil analysis laboratory; they can interpret results, monitor trends, and help set safe, data-driven optimization strategies. One-off test results are useful, but trend data over time is essential to optimize drain intervals without risk confidently.

Optimizing lubricant drain intervals can reduce costs, extend oil life, and improve reliability. However, success depends on careful planning and data-based decision-making through oil analysis. Partnering with your laboratory experts ensures changes are made with reliability in mind.