During inspection and maintenance activities, it is common to identify possible sources of lubrication-related failures, and one of the most recurrent is the constant leakage of oil in grease-lubricated bearings. This problem, often underestimated, can cause dryness and premature hardening of the grease, compromising the reliability and performance of the assets.

What Is Exudation and How Does It Affect Lubrication?

A exudation It is a condition where lubricating oil separates from the thickener (the structure that holds the oil), resulting in a hardening of the grease. Small releases of oil are normal because the thickener works like a sponge, releasing oil in a controlled manner to lubricate. However, when oil separation is excessive, grease hardens prematurely and loses its ability to protect contact surfaces, resulting in accelerated failures and increased maintenance requirements

How Does Temperature Impact Grease Exudation and Hardening?

High temperature is one of the critical factors for separating oil from grease. In extreme conditions, the oil can reach its dropping point, which causes it to lose viscosity and separate more easily from the thickener. This phenomenon can occur due to:

- Excess Grease: When there is excessive lubrication, the bearing needs to disperse excess lubricant, which generates heat and accelerates grease degradation.

- Long Periods Without Relubrication: The absence of purging and the lack of relubrication at appropriate intervals make it difficult to remove old grease, which can oxidize and harden over time, reducing the efficiency of the lubricant.

- Lack of Purge During Lubrication: In bearings without relief valves or drains, excess pressure caused by the application of new grease pushes the oil, separating it from the thickener and contributing to premature hardening.

- Centrifugal Forces and High Speeds: In high-speed bearings, centrifugal forces act on the oil, forcing it to separate from the thickener, especially in greases not suitable for this type of operation.

- Incompatible Lubricant: The incorrect choice of lubricant for the type of operation, temperature and load can also favor oil separation, compromising the performance of the asset.

Other Factors Contributing to Hardening and Premature Failure

In addition to exudation and the impact of temperature, cross-contamination between different lubricants can negatively influence the stability of the grease. For example, using a higher viscosity grease can result in an increased shear strength, which generates additional heat and accelerates oil separation, especially in high-speed bearings.

In addition, the lack of contamination control, such as the entry of particles and moisture, degrades the thickener, increasing friction and operating temperature, which leads to hardening and decreased lubricant life.

Practices and Procedures to Minimize Hardening and Improve Grease Life

Implementing a structured routine based on operating conditions is critical to reducing the risk of hardening and premature failure. Best practices include:

- Check the DN and NDM Factor of the Lubricant: These factors indicate the suitability of the grease for high-speed operations. Lubricants for high-speed bearings must have low viscosity and shear strength, avoiding premature separation.

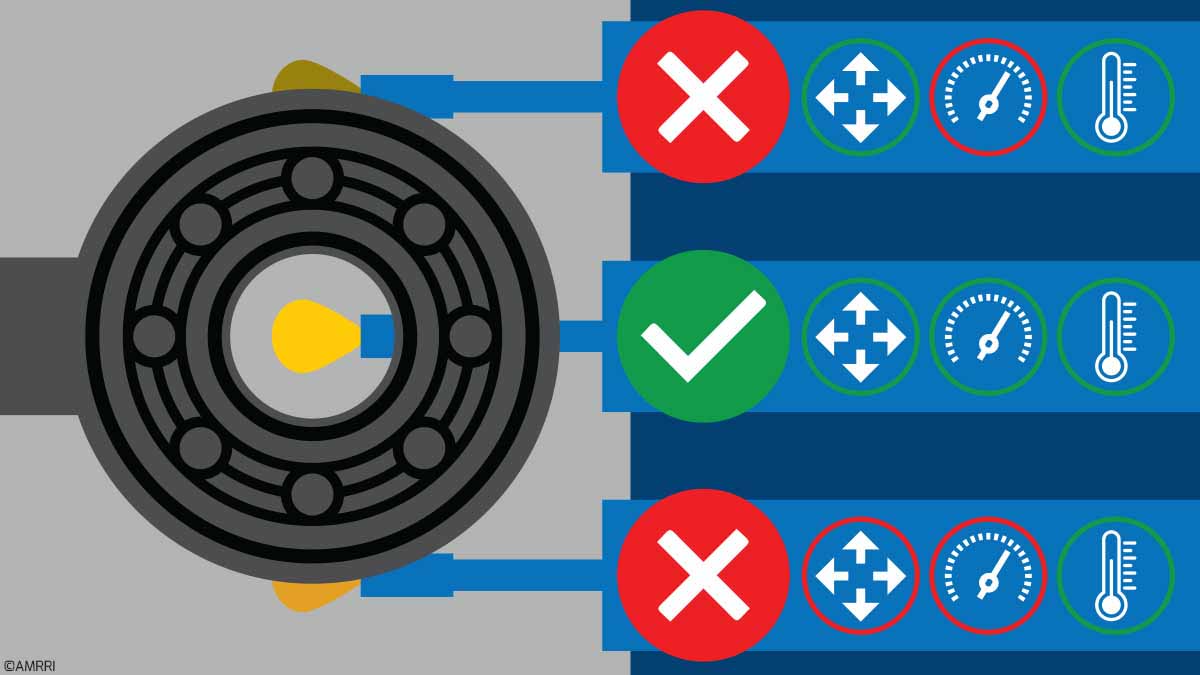

- Consider Operating Conditions: It is essential to evaluate whether the grease can withstand high centrifugal forces, high loads, and extreme temperatures. Periodic analysis of the condition of the asset is essential to ensure that the lubricant used is adequate.

- Adopt Appropriate Relubrication Intervals: Establish relubrication periods adjusted to the actual conditions of the equipment, considering factors such as operating speed, load, and temperature. This approach helps prevent grease degradation and oxidation.

- Prevent Cavity Formation When Handling Grease: When grease is removed from the packaging, avoid cavities that create low-pressure zones, which makes it easier for the oil to drain out. This simple care can prevent premature grease degradation.

- Ultrasonic Lubrication: Ultrasound tools allow real-time monitoring of the amount of lubricant required. This prevents overheating and reduces pressure on the system, helping to maintain application efficiency and prevent unnecessary heating.

- Contamination Control: Use old grease sealing and purging techniques to minimize the ingress of solid and liquid contaminants. A clean environment with low presence of particles increases the useful life of the grease.

Benefits of a Condition-Based Lubrication Program

Implementing a lubrication program that is based on operating conditions (conditioned lubrication) maximizes efficiency and reduces unplanned downtime. By adopting a plan with continuous monitoring and techniques such as ultrasound, it is possible to identify relubrication needs with greater precision, adjusting the frequency and quantity of application according to the actual wear and tear of the asset.

Case Study: Excess Pressure and Equipment Damage

A real case illustrates well the importance of a controlled lubrication program: in one factory, the lack of purging and the application of excessive pressure during lubrication resulted in the rupture of the seals, causing grease to accumulate inside the electric motor. This buildup caused heating and bearing failures, resulting in irreversible damage to the engine and impacting plant productivity.

Maximize Asset Life with Best Lubrication Practices

By following these practices, it is possible to achieve significant operational gains, minimizing lubrication failures and promoting asset reliability. The adoption of a structured lubrication plan, combined with monitoring tools, allows not only to reduce maintenance costs, but also to extend the useful life of components and avoid unexpected downtime.