In my experience, flash point is one of the most misunderstood numbers on a product data sheet. Most people ignore it, as it is rare for oil system temperatures to approach the flash point range (typically >200°C). When it does become a concern, there is often confusion regarding safe working limits, operating limits, and flammability versus flash.

Quick summary:

- Flash point is not a physical property of a lubricating oil

- The flash point of an oil can be used as a diagnostic tool

- The manufacturer should define safe working limits

So, First of All, What Is Flash Point?

The flash point of lubricating oil is not a physical property similar to viscosity at 40oC or water content; instead, the result is defined only in terms of the test method used.

If that’s a little difficult to understand, think about it this way: you have a defined height – it is a physical property of your body. There are numerous methods to measure that as accurately as possible.

But what about your strength? Strength measurements can be standardized by making people lift weights, making the units for strength kilograms. But the number would vary depending on whether the weights were lifted on a cable machine, a barbell, a dumbbell, or whether the lifting type is a squat, deadlift, bench press, etc.

Flash point testing is designed to measure the temperature at which the vapors of a lubricant ignite. However, this temperature will vary greatly depending on conditions. For example, a thin puddle of lubricants in the sun will experience a different flash point than the same puddle in which a light breeze displaces the vapors.

From the ASTM D6450 document, we have the following:

Flash point values are not a constant physical-chemical property of materials tested. They are a function of the apparatus design, the condition of the apparatus used, and the operational procedure carried out.

What Are the Common Flash Point Test Methods?

Two predominant types of Flash Point tests have been developed – closed and open cup. All the methods generally have the following features:

- The lubricant sample is held in a vessel

- The sample is heated in temperature increments

- At each increment, an ignition source is introduced

- If no ignition is detected, the sample is heated to a higher temperature

Open cup methods allow the vessel to be open to atmosphere while the vessels in closed cup methods are sealed chambers.

The venting of light ends to the atmosphere causes open-cup methods to register higher flash point values than closed-cup methods; as most industrial thermal systems are closed to atmosphere, closed-cup methods have been adopted by industry in the belief that they more closely simulate the operating conditions.

Within closed cup flash point test methods, the most popular is the Pensky Marten Closed Cup test (PMCC – ASTM D93a). In this test method, the sealed chamber contains 75mL of oil mixed by a magnetic stirrer. After heating to the test temperature, a flame is passed over the oil – the sample is deemed to have flashed if:

A large flame appears and instantaneously propagates itself over the entire surface of the test specimen.

There are several limitations to this test, which have prompted the development of more modern test methods:

- Safety concerns over open flames in laboratory conditions

- Large volume of oil required for the test

- In some circumstances, application of the test flame can cause a blue “halo” or enlarged flame that is mistaken for a flash, resulting in “false positives”

To address the issues outlined above, ASTM D6450 was developed. In this method, a 4mL vessel containing 1mL of oil is heated in increments, and an electric arc passes through the sample container.

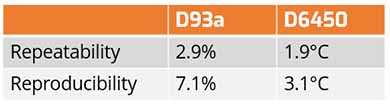

If no flash is detected, 1.5mL of fresh air is pumped into the vessel to ensure that the vessel contains enough oxygen to promote flashing of the sample. This test method has tighter controls and therefore improved repeatability and reproducibility over the D93a test method for oils with flash points above 65°C:

In previous experience with a major oil supplier, I have found variations between flash point testing methods of over 100°C across different laboratories.

If Flash Points Vary Depending on The Test Method, How Can We Use Them?

Firstly, any limits prescribed by the OEM should be test-specific. Once again, from ASTM D6450:

If the user’s specification requires a defined flash point method other than this test method, neither this test method nor any other method should be substituted for the prescribed method without obtaining comparative data and an agreement from the specifier.

For these reasons, among others, we cannot draw a straight line between an oil’s flash point and the safe working temperature of an oil system. Not only will different test methods yield different results, but operating conditions will dictate an oil’s proclivity to ignition, such as whether the system is open or closed.

Therefore, if an oil user is seeking guidance on a safe flash point for a system, they should consult the OEM. The OEM should give both a flash point deemed safe for the equipment AND the test criteria used to determine this flash point.

Often, safe working temperatures will be guided by the oil’s auto-ignition temperature, with some safety margin and an emphasis on ensuring there are no ignition sources close by.

While flash point testing cannot yield a safe operating temperature under normal circumstances, changes in flash point over time can give information about system degradation. For example, decreases in flash points indicate the production of “light ends” that are likely a direct consequence of thermal cracking.

A localized hot spot in the system is potentially contributing to this cracking. Alternatively, a gradually increasing flash point could indicate that the light ends are being vented. A slight increase in the bulk oil viscosity would typically accompany this.

Finally, abrupt changes in flash point could indicate contamination of the system with an incorrect oil top-up, as is the case when large viscosity changes are observed in oil systems.

I recommend that any operator of a thermal system review OEM documentation for the thermal oil systems to obtain any recommendations regarding test limits for Flash Point. These test limits must be defined in terms of a specific test method.