Case study data, information and images provided by POLARIS Laboratories®

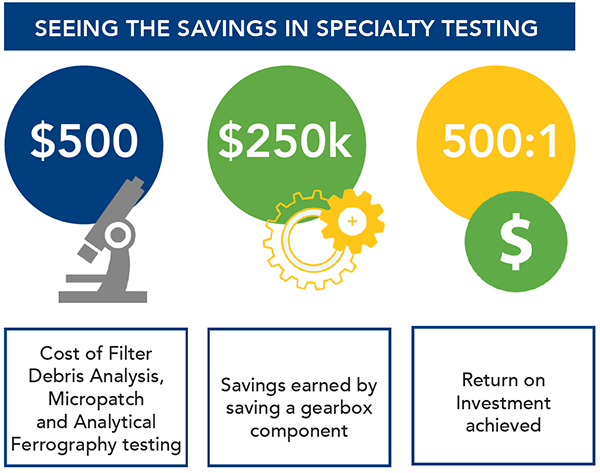

Routine fluid analysis can help to monitor equipment conditions and extend component life. But, by going the extra step and performing Filter Debris Analysis, and other tests to analyze particles found within the filter, one customer could identify harmful debris, identify the root cause of the problem, and prevent the replacement of a costly gearbox.

Consistent Unit Failure Leads to Further Testing

A customer in the power generation industry was performing textbook, routine oil analysis on the operation’s gearbox units as a form of condition monitoring. One gearbox unit was consistently experiencing failure. After seeing a high-severity sample report from the component, the POLARIS Laboratories® data analysis team suggested the customer perform Filter Debris Analysis (FDA) on the component. This would allow the maintenance team to perform root cause analysis and discover why the gearbox was failing, halting production and losing money.

Investigating the Issue

The Filter Debris Analysis results came back highly severe – the debris found on the oil filter was too thick in consistency to perform a proper, standard analysis. The data analysis team sent the sample back to the laboratory to prepare it for Analytical Ferrography (using a powerful microscope to see and identify debris, wear mechanisms, and contaminants in the filter). To the team’s surprise, the Analytical Ferrography tests came back with low severity, meaning no potential problems were found. This means the customers’ oil filters were serving their purpose. But this doesn’t answer the question as to why the gearbox was failing.

And the Answer Is …

Puzzled by these results, the team prepared the sample for a Micropatch test. Micropatch testing involves a similar process as Analytical Ferrography, but instead of catching only ferrous material, a filter patch collects all particulates in the oil. This allows ferrous wear, non-ferrous wear, abrasives, and debris to be collected and analyzed using a microscope. After this test was performed, the real root-causing problem was revealed: varnish.

Varnish can cause hot spots, increase machine temperature, and result in filter plugging. In this case, the varnish build-up overheated the gear teeth causing fatigue and stress cracks that eventually lead to the component failing. Through performing these specialty tests, the customer found a dangerous amount of fatigue wear, rubbing, and corrosive wear, along with dirt and debris within their filters and equipment.

Taking Actions to See Savings

The power generation customer continued to perform Filter Debris Analysis, flushed all gearbox units, and switched to a different oil with higher oxidative stability. After taking these actions, the other gearboxes were no longer at risk of failure. The cost of each gearbox unit is approximately $250,000, and having a large amount of these units in their operation, the company’s savings steadily increases as they continue to identify the root cause of failure.