featured

Seal the Deal: Practical Steps to Combat Contamination in Pumps

What Causes Wear? Contamination has frequently been identified as one of the major causes of premature wear on...

recommended

Oil Consolidation Reimagined: The 5S Method for Smarter Lubrication Practices

When we walk into a pharmacy, there are thousands of items. Some of them do the same job but have different names and...

Lubrication’s Hall of Fame: Meet the Top 10 Pioneers

In 1966, at the height of the "swinging sixties" movement, the world of lubrication, friction, and wear finally...

When Bearings Fail: A Fire Pump’s Hard Lesson in Reliability

In a Middle Eastern refinery, a newly commissioned fire water pump, crucial for emergency services, experienced...

How to Select Oil Analysis Tools That Align with High-Value KPIs

Oil analysis is critical to any reliability program, serving as an effective predictive tool for potential equipment...

Lubrication Scheduling Software

With capabilities not found in spreadsheets or CMMS systems, LUBE-IT manages every task at every lube point providing lube techs with all the information they need to keep equipment running and reliable.

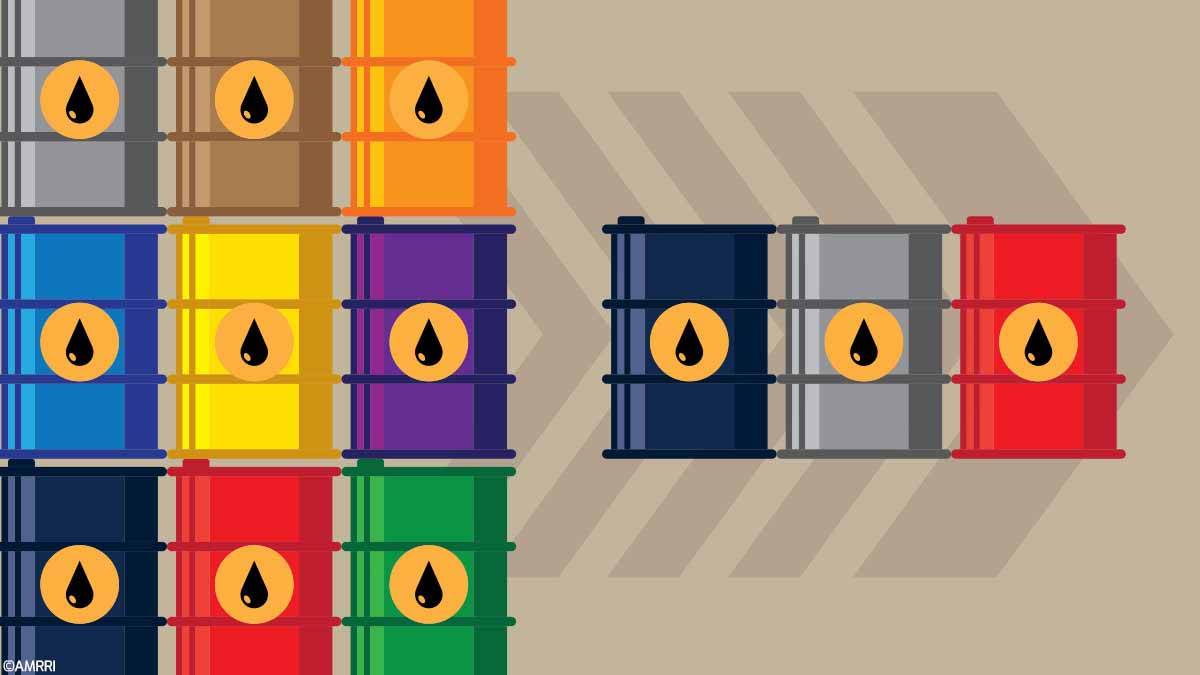

How Lubricant Consolidation Reduces Misapplication and Downtime Risk

What's the Right Number of Lubricants for Your Plant? Over the years, I have been to sites with either too many or too few lubricant types. Both scenarios are potentially costly. On the one hand, too many types of lubricant are costly in terms of purchase price and...

How to Interpret RPVOT Regions for Better Lubricant Decisions

It is very likely that you have encountered the RPVOT (Rotating Pressure Vessel Oxidation Test), a laboratory test developed in the 1960s and later standardized by ASTM D2272. It measures the antioxidant stability of lubricating oils by accelerating oxidation in a...

ICML Announces New Board Members With Global Industry Expertise

The International Council for Machinery Lubrication (ICML) today announced the election of three new members to its Board of Directors: Kelley Evans, Matthew G. Collins, and Mike Ramsey. Their appointments became effective January 23, 2026. The election of Evans,...

From Oil Samples to Algorithms: Leveraging AI and Automations

Maintenance teams are entering a new era, one where data-driven insights enable automation and transform how equipment health is monitored and maintained. For years, the industry has been moving from preventive maintenance to predictive maintenance, but what’s next?...

How EGR Failures Destroy Engines – and How Oil Analysis Detects Them

The EGR (Exhaust Gas Recirculation) system recirculates a fraction of the exhaust gases into the intake manifold to lower combustion temperature, reduce NOx emissions, and, in some cases, improve fuel consumption in both diesel and gasoline engines. This recirculation...