When I go into industrial plants and tell the Lubrication Team, aka, oilers and greasers, that they are Tribologists, I usually get a look of confusion on how they would fit in. When you first think of Tribology, your thoughts may immediately go to all the great PhD...

Reliability

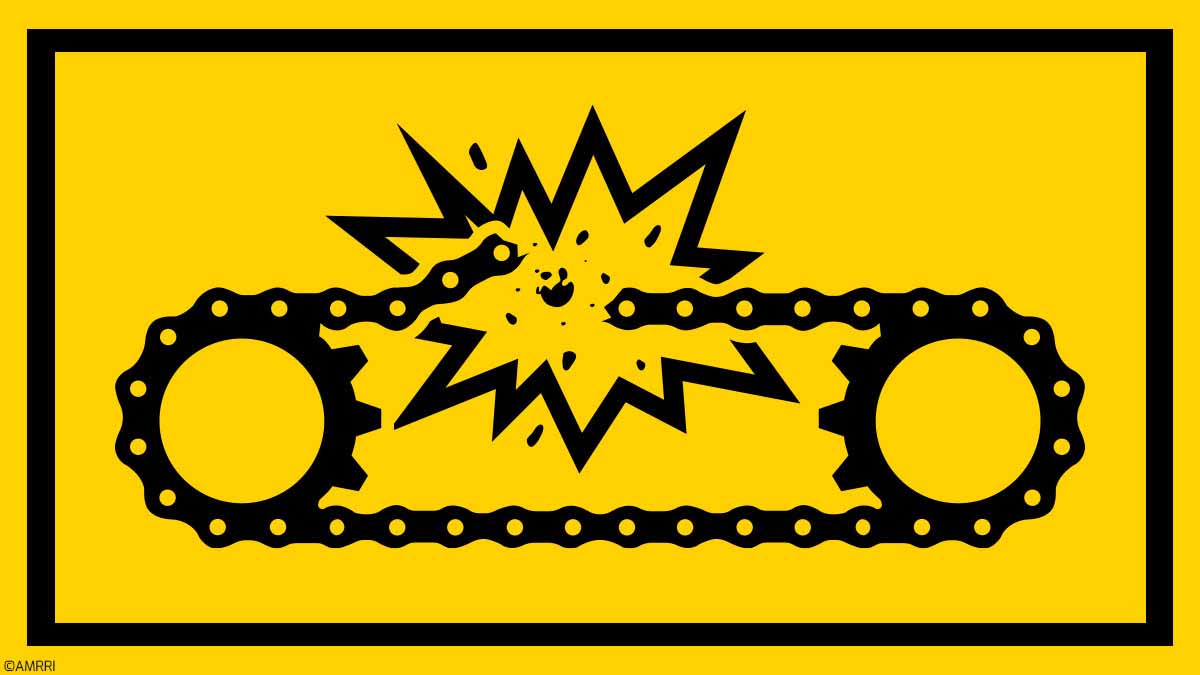

Preventing “Creep to Failure” in Mechanical Systems

In my recent article, "Improve The Reliability of Hydraulic Systems for Just Pennies A Day," I used the term "creep to failure." It describes mechanical systems that continue to work, albeit inefficiently, for extended periods despite suffering from disrespect, abuse,...

Machine Mapping: Charting Assets for Remarkable Reliability

Making sense of any production or maintenance workflow, process, or procedure requires a textual map in the form of a diagram, visual representation, or an ordered text list that shows or describes the relative position of the parts of something. Maintenance teams...

7 Ways RAM Models Boost Organizational Performance

The fundamental purpose of Reliability, Availability, and Maintainability (RAM) modeling is quantifying system performance, typically in a future interval of time. A system is a collection of items whose coordinated operation leads to the output, generally a...

Four Simple Fixes to Improve Your Maintenance Stockroom Processes

Many organizations struggle to manage maintenance stockrooms effectively, impacting the business's bottom line. In organizations with inefficient MRO processes, it's common to find the site with high levels of reactive breakdowns, maintenance delays due to part...

Qualified Reliability Professionals: The Lone Hope for American Industries?

Many years ago, I wrote a book entitled The Death of Reliability, Is it too late to resurrect the one true competitive advantage? I wrote the book because of my growing concern that we are losing the experience and skills necessary to deliver reliability. It is not...

Hardwiring Reliability: How Executive Sponsorship Can Drive Culture Change

This article chronicles a reliability journey at a chemical manufacturer in the Southeastern United States. Implementing a reliability-based maintenance program has tremendous business benefits – the kind of impact that executives get excited about. Before our plant...

Why Reliability is Failing

My focus is on what and how companies invest in their equipment to drive results. As someone who has worked in maintenance and reliability for more than 40 years, I enjoy learning about what is new. However, the reoccurring mistake in all equipment purchases is the...

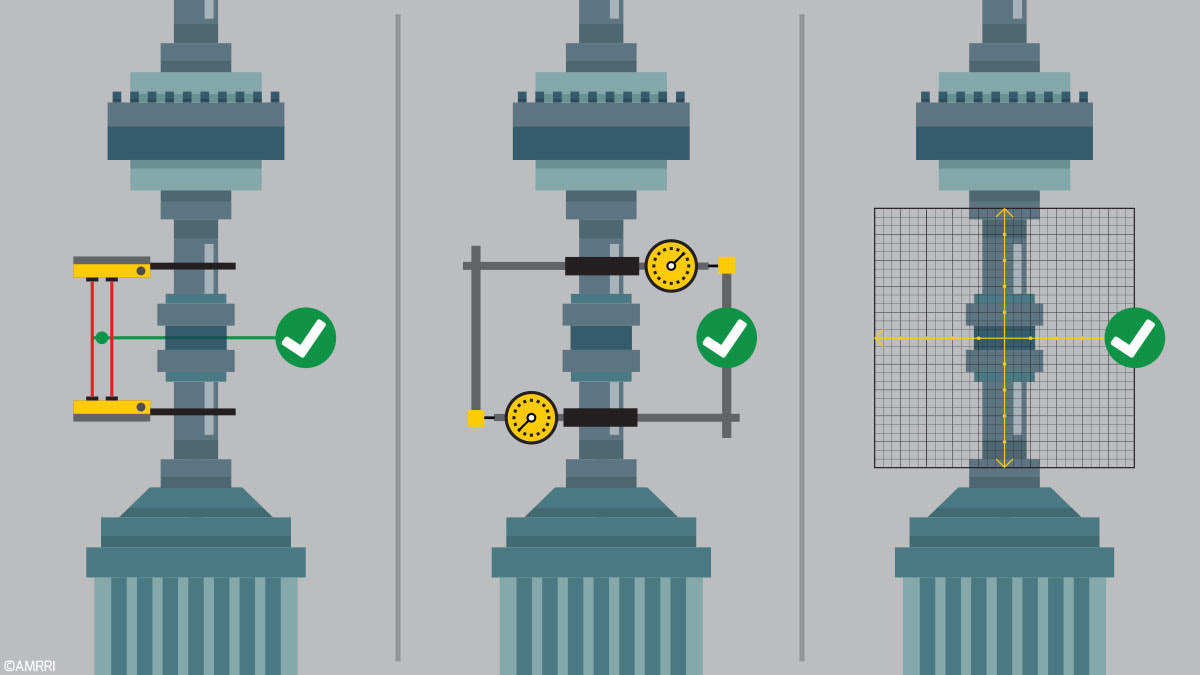

Precise Alignment Principles for Field Application

The Precision Lubrication team recently spoke with Ian McKinnon about precise alignment. Ian is a pioneer in the maintenance field, a passionate instructor, and a founding principal of Reliability Solutions, LP. Why don’t you use lasers to demonstrate alignments in...