When the lube room resembles a crime scene - chaotic storage, unlabeled containers, questionable handling tools, inconsistent transfer practices - it becomes a hidden driver of accelerated wear, additive depletion, ingress-driven contamination, and component life...

Contamination Control

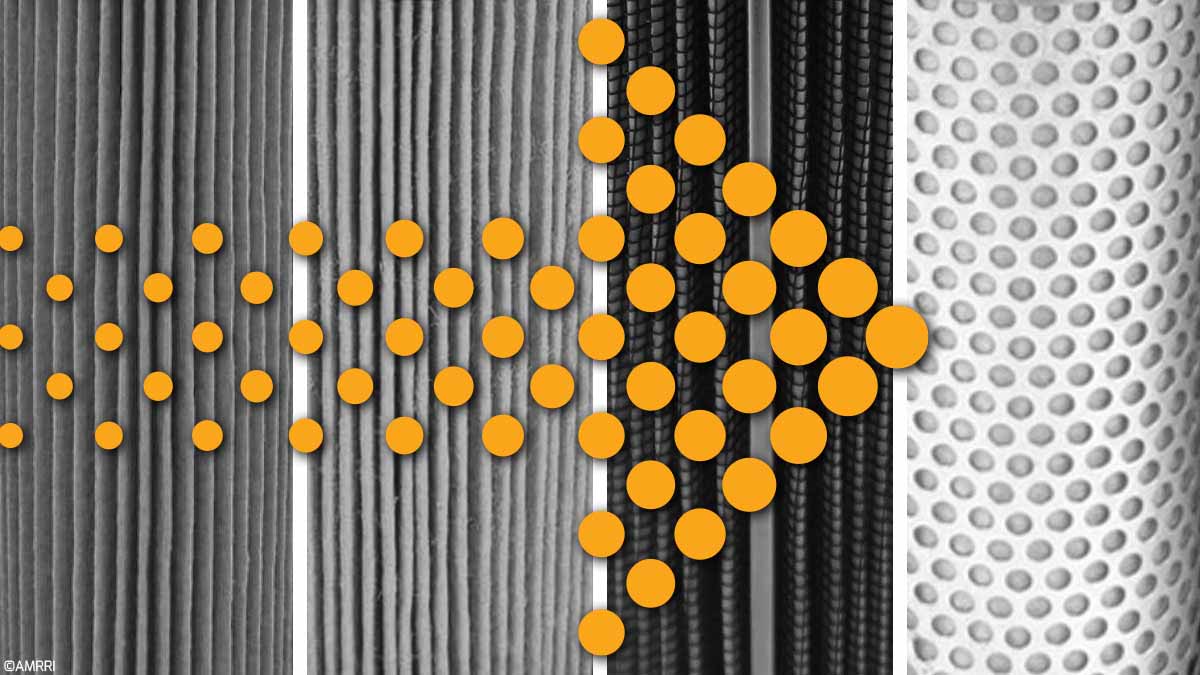

How Fine Is Too Fine in Oil Filtration Systems?

As with many things in lubrication, sometimes too much is as bad as too little. This is certainly the case with filtration. How Fine Is Too Fine for Your Oil Filter? To answer that, we need to look at several factors. First, let’s dispel a few myths about fine...

Lubricant Varnish: How to Detect, Prevent and Fight this Silent Enemy

Varnish formation is one of the most critical and often overlooked challenges faced by industrial lubrication systems, especially in high-performance applications such as steam turbines, gas turbines, compressors, and precision hydraulic systems. Even when invisible...

Extending Hydraulic Oil Life Through Targeted Varnish Removal

Hydraulic presses in Oriented Strand Board (OSB) mills are central and indispensable to OSB production. They exert an immense, uniform force required to compress wood strands and resin into durable panels, operating under exacting temperature and pressure conditions....

Lubrication Wins That Also Boost Efficiency and Longevity

Over the years, the one thing that has always struck me is how few reliability teams work with their counterparts in the Health and Safety and Environmental departments. Linking Lubrication to ESG and Sustainability Goals To quote the guru, Ron Moore, in his article,...

Why Air Breathers Are a Critical but Overlooked Contamination Barrier

Over the past two decades, while conducting numerous Lubrication Benchmark Assessment audits across a wide range of industries—from Oil and Gas, refineries, petrochemical plants, and power generation facilities, I have witnessed one of the most neglected areas of...

How to Set Oil Cleanliness Targets That Extend Gearbox Life

Solid Particle Cleanliness In my previous articles, I have discussed how to achieve cleanliness within gearboxes and pumps, examining the entire aspect of solid particulate contamination ingress. However, I was recently asked by an engineer following the above...

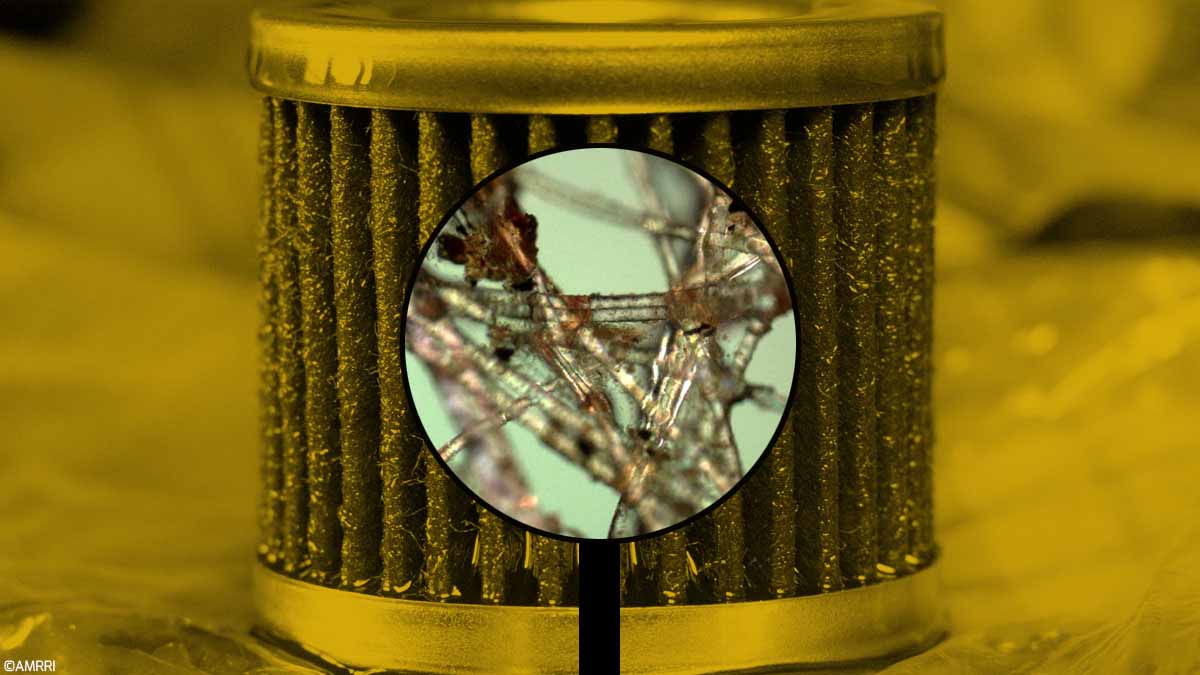

Why Oil Filter Analysis Should Be in Every Reliability Program

Condition monitoring tools such as vibration analysis, ultrasound, oil analysis, and thermography are mainstays of a condition-based maintenance strategy, each providing a unique perspective on the health of critical rotating and reciprocating assets. Vibration...

The Economics of Clean Oil: Why Prevention Beats Repair Every Time

When it comes to hydraulic systems, oil contamination is one of the most insidious and persistent enemies. It is estimated that about 80% of failures in these systems are directly related to fluid contamination. The issue goes beyond simply cleaning the oil; It...

How to Choose the Best Filter Location for Contamination Control

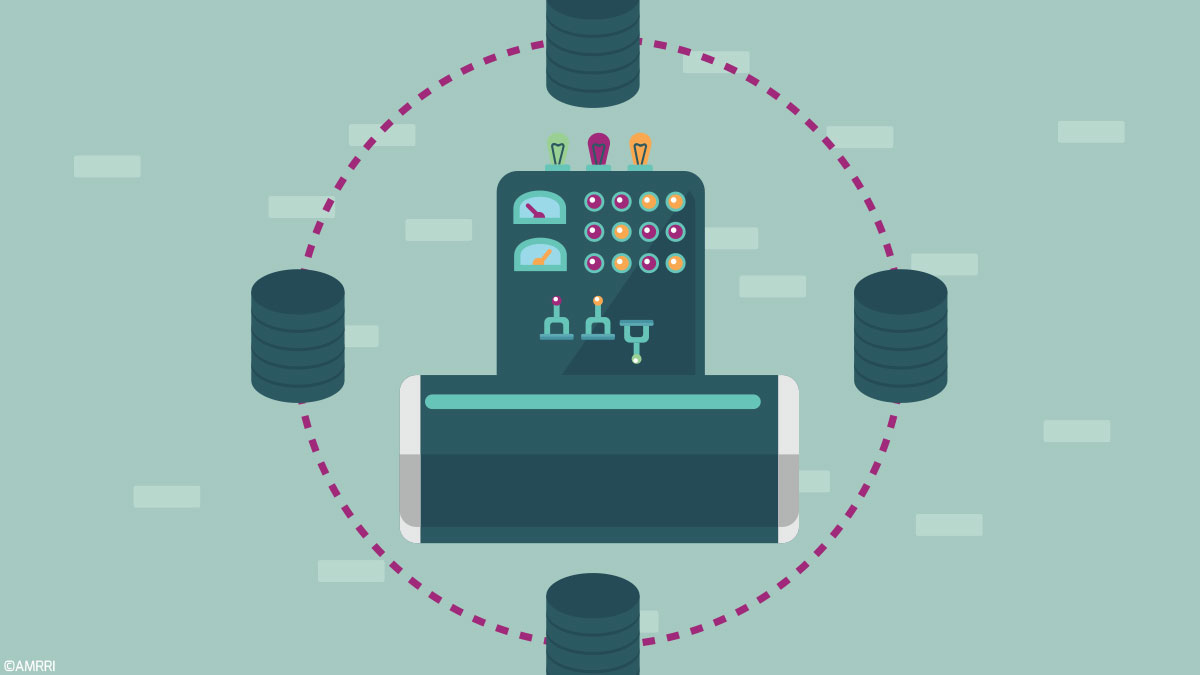

Achieving proactive maintenance involves three key steps: setting cleanliness targets, implementing specific actions to meet those targets, and frequently measuring contaminant levels. This article focuses on the second step—specifically, how to choose the most...