Whether we realize this or not, oil refineries are critical in our everyday lives. They convert crude products into diesel, gasoline, LPG, and plastics. The equipment in this plant must withstand very high temperatures, sometimes over 500°C (in the distillation unit)....

Case Studies

When Bearings Fail: A Fire Pump’s Hard Lesson in Reliability

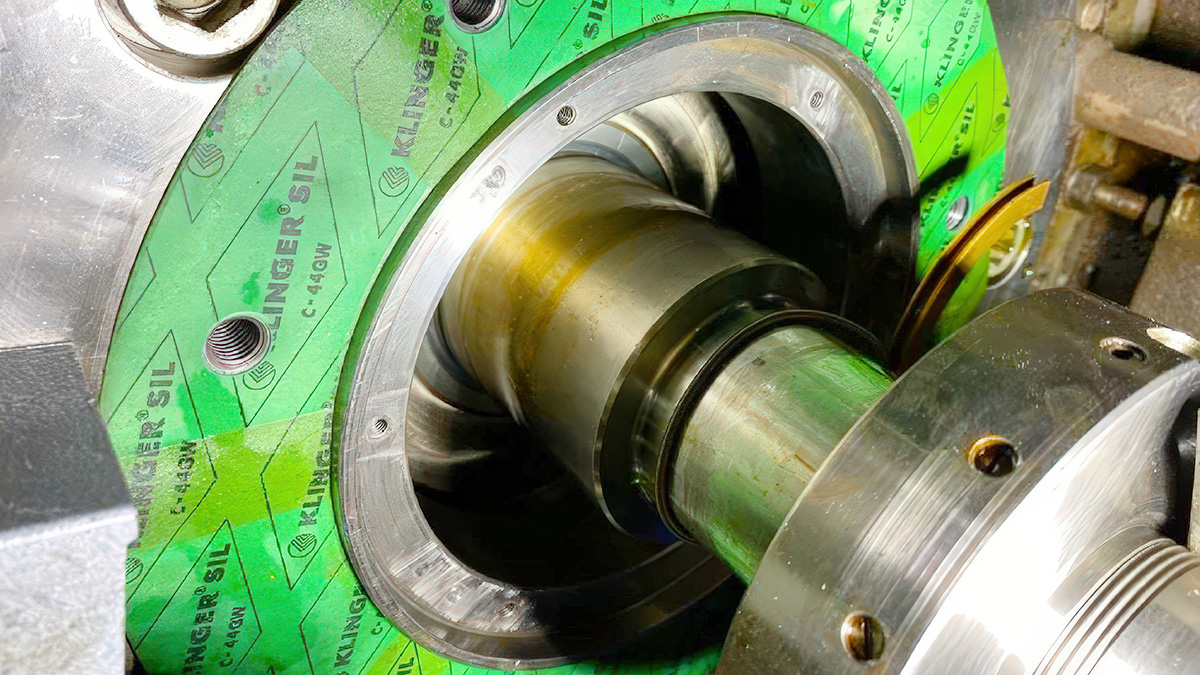

In a Middle Eastern refinery, a newly commissioned fire water pump, crucial for emergency services, experienced repeated high temperatures at the non-drive end (NDE) bearing during periodic test runs. Over time, these temperature spikes eventually led to a premature...

Downtime Disaster: The Lubricant Mix-Up That Shut Down Production

Lubricants are the lifeblood of machinery, and every decision, from selection, purchase, storage, dispensing, and health management, plays a critical role in ensuring the reliable operation of essential machines. A minor oversight can lead to significant downtime,...

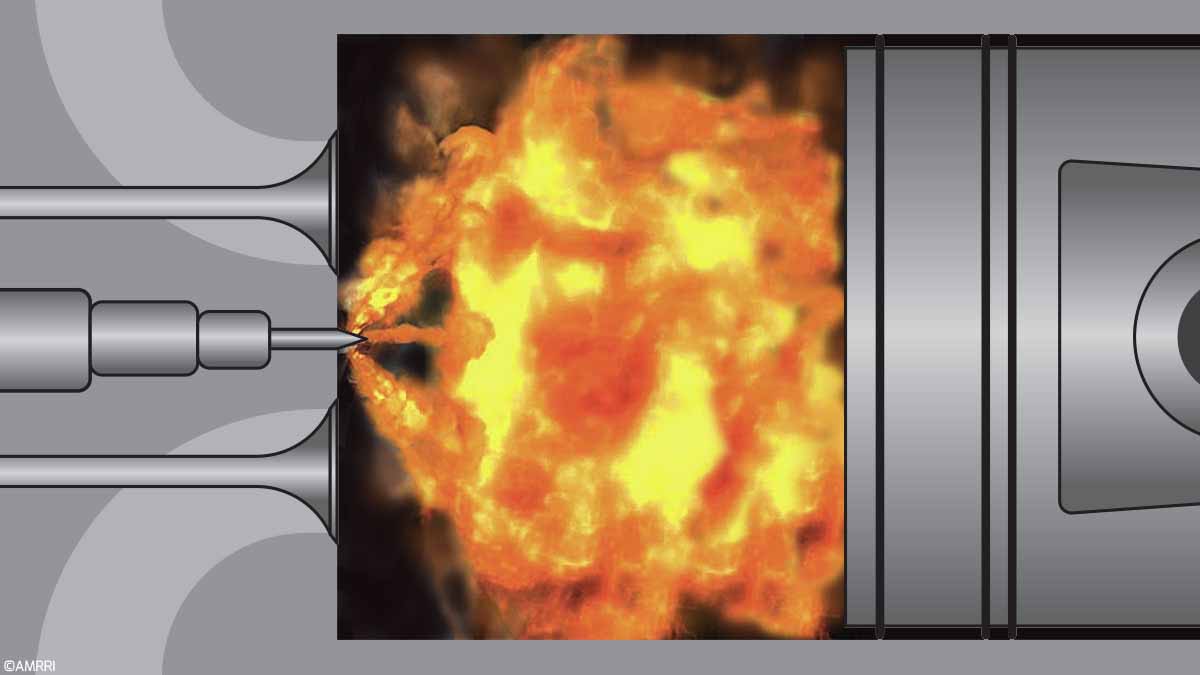

Case Study: Monitoring Diesel Engine Combustion Efficiency with Oil Analysis

Diesel engines are the driving force powering many modern transportation and industry applications. They can be found in vehicles and machinery, from trucks to marine vessels. In the port industry, diesel engines are found in Rubber Tire Gantry (RTG), Terminal...

The Bottom Line of Reliability: Fluid Analysis Cuts Maintenance Costs

Fluid analysis is a powerful tool in the preventive maintenance toolbox of many equipment and maintenance managers in industries ranging from construction to aggregates to mining to marine. Efficiently managed programs provide considerable benefits that translate...

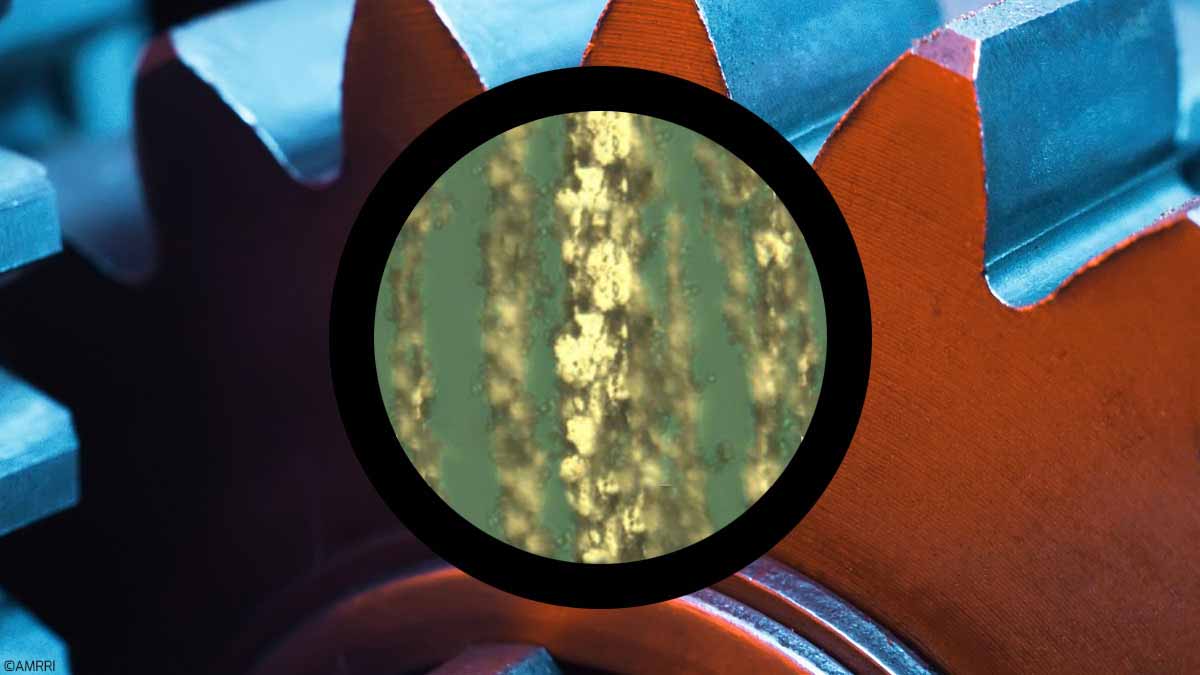

Case Study: Gearbox Condition Monitoring with Wear Debris Analysis

Wear monitoring is one of the primary objectives of oil analysis for predictive maintenance. Many oil analysis tests are considered suitable for wear debris analysis, and some, like elemental analysis and Wear Particle Index, are recommended within routine analytical...

Paper Machine Oil Condition Monitoring Benefits and Case Study

Oil analysis on oil reservoirs, such as a paper machine, provides much more value than most maintenance managers realize. Regular reservoir oil sampling can provide the following: Reactive information, such as a spike in wear metals identifying a failed bearing or...

Hardwiring Reliability: How Executive Sponsorship Can Drive Culture Change

This article chronicles a reliability journey at a chemical manufacturer in the Southeastern United States. Implementing a reliability-based maintenance program has tremendous business benefits – the kind of impact that executives get excited about. Before our plant...

How Grease Analysis Helped Expose a Hidden Plant

Those who have worked in or around maintenance and reliability have probably heard about the hidden plant. This term refers to that portion of the productivity of any industry that, for some reason, is wasted and goes completely unnoticed in the eyes of the...

Ensuring Compatibility: The Importance of Proper Grease Analysis

I have been living in Houston, Texas, for a little over three years, and to this day, when I talk to a friend, the first sentence I hear is, “Houston, we have a problem.” It’s a trendy phrase that has become an icon for the Texan city. However, as often happens, there...