The old battle cry in the hydraulics world is “flow makes it go.” However, pressure determines the ability of actuators to move heavy loads. Therefore, flow and pressure together define the total power of the hydraulic system.

Hydraulic Oil Viscosity

Hydraulic oil must contain the correct viscosity, or the system cannot develop that power or operate properly. Viscosity is the most crucial property of lubrication, yet it is shrouded in mystery and confusion.

Viscosity is a measurement of a fluid’s internal resistance to flow. This definition is based on a specific liquid’s molecules having more or less internal friction.

The typical viscosities of hydraulic fluids are ISO VG 32, 46, and even 68, but they are available in an even wider range of ISO VG 22 to 100, which are also used in hydraulics. Selecting the correct viscosity is a balancing act that requires juggling two conflicting requirements.

Effects of Operating Temperature

This is because oil viscosity reduces rapidly with the increasing temperature of the oil and increases with decreasing temperature of the oil. This means that operating temperature is king. Controlling operating temperature reigns as the predominant viscosity-affecting variable.

Too hot oil will easily bypass through pumps, valves, and cylinders. This bypassing causes additional heat and a slowdown of the system. Cold, thick oil will cause the system to operate sluggishly or erratically. The main issue with cold oil is pump cavitation.

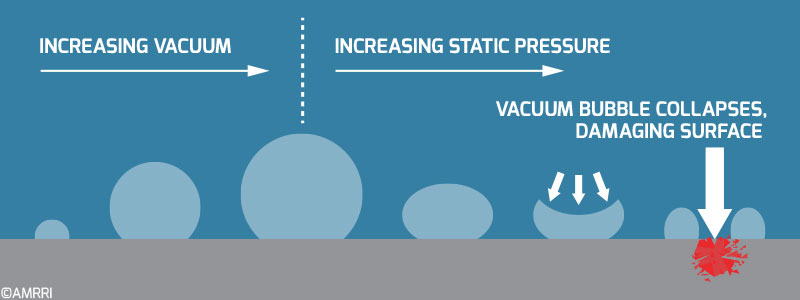

When the viscous oil restricts the fluid’s flow enough at the pump’s inlet, the pressure drops low enough (vacuum increases) that the liquid can’t exist as oil but vaporizes or boils into a gas. The little gas pockets released not only do not lubricate well but when exposed to high pressure at the pump outlet, the cavity walls of the bubbles collapse or implode.

The Cavitation Process

This reaction generates tons of pounds of force per square inch and can produce destructive micro jets of oil that collide against the internal pump surfaces at extremely high velocities. Catastrophic pump failure and distribution of pump fragments throughout the system will occur.

Hydraulic oil must be light enough at very low starting temperatures to be easily sucked into the pump, preventing cavitation. But it must also be heavy enough at high operating temperatures to avoid wear and internal leakage inside the pump, resulting in inefficient operation. Be careful not to get too heavy or too light of oil, or it could result in excessive heat.

Address this dilemma by using high-viscosity index fluids. With high VI hydraulic fluids, the optimum operating range of acceptable viscosities spreads over a wider temperature range, and the temperature range for the highest overall efficiency is also wider. So you save energy. To make a high VI fluid (with a VI considerably more than 100), the oil supplier can use a high VI base oil, viscosity modifiers, or both.

Individual pump manufacturers specify their own viscosity requirements and operating temperature ranges. As a good rule of thumb, I recommend these temperature mile markers.

- Minimum start-up temperature – 40°F

- Ideal operating temperature – 120°F

- Max temperature for 100% life – 140°F

- System noise may increase due to thinner oil.

- Oil life is cut in half at 140°F – 155°F.

Operating Temperature as a System Health Indicator

Hydraulic oil starts breaking down at around 140°F. For every 15° above 140°, the life of the oil is cut in half. Hydraulic oil life is halved at 155°F and halved again at 170°F due to the temperature dependence of oil and its reaction rate, as per the Arrhenius equation.

So remember that the site glass thermometer/ temperature gauge on your reservoir is more than a shiny piece of costume jewelry on the side of your tank. It is a critical tool for maintaining the viscosity of your oil and the reliability of your system.

Record and rigorously track the system’s operating temperature, which may vary with season and reservoir location. Regard it as a vital system health indicator and troubleshooting tool.

Reliability Solutions offers hydraulic training with the 3H approach to learning. The Hybrid, Heuristic, Hands-on program provides a balanced blend of computer-based pre-work, live online training of fundamentals, applied assignments to be completed on your equipment, and a live, hands-on, onsite session with our hydraulic demonstrators. For more information, contact Katie Dickson at katiedickson@reliabilitysolutions.net.