Sometimes we can spend hours poring over technical data sheets, comparing oil performances, and finally selecting the “right” oil which aligns with the needs of our equipment. Then, within 2 months, the oil degrades, our machines shut down, and we have a bunch of maintenance repairs lined up. What went wrong? We clearly had the “right” oil in the equipment; everything should have worked beautifully. This is where the awareness of lubrication and its practices becomes critical.

Having the correct oil is only one part of the puzzle. Being able to deliver that oil in its purest, cleanest form to the machine is often one of the other pieces that go missing. Another piece is selecting the right oil, not just based on the sales guy’s advice, but on the actual operating conditions of your machine. In this article, we dive a bit deeper into ways you can align the right oil with the proper practices, or avoid the wrong ones, to help extend the life of your asset.

Spec Sheet vs Strategy

For this example, we will consider a turbine oil selection. If a customer wants to change the oil in their turbine, then they may consider the following:

- What are the OEM specifications that need to be met?

- Is this oil available from the local supplier?

- How does it compare to other oils on the market?

- Does the cost justify the value? (or will the purchasing department want something cheaper?

For most of these questions, engineers or the person tasked with selecting the oil can readily find the answers in the oil’s technical data sheet and by talking to their sales representative. But if we dive a bit deeper, are we selecting the right oil for the operating and environmental conditions? Let’s examine the selection of a turbine oil for the Siemens SGT 200 Gas turbine that meets the Siemens TLV 9013 04 specification.

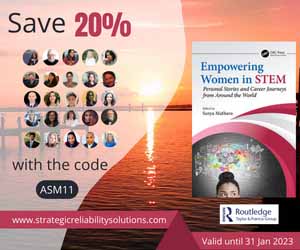

As seen in this document from Shell Lubricants, a few of their products meet that specification, namely Shell Turbo T, Turbo S2GX, Turbo S4X & Turbo S4GX.

Figure 1: Shell Turbo Family for the Siemens TLV 9013 04 Specification

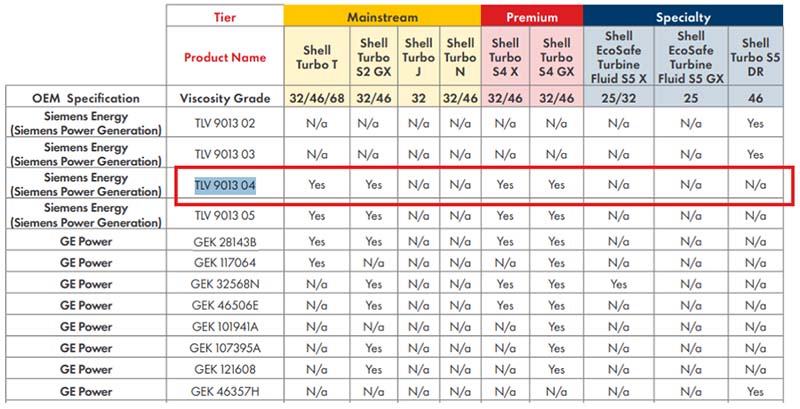

On the other hand, Mobil provides some solutions as well, namely, Mobil DTE 732, 746, or DTE 832, 846

Figure 2: Mobil DTE 700 & 800 Series meeting the Siemens TLV 9013 04 Specification

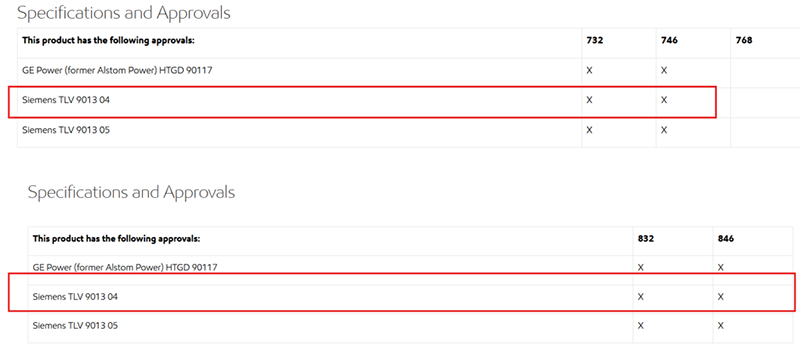

Chevron also provides an option of Chevron GST as follows:

Figure 3: Chevron GST oil meeting the Siemens TLV 9013 04 specification

With so many options, how can one choose the “right” oil? They all meet the required Siemens specification, TLV 9013 04. This is where the data sheets, OEM manual, and knowledge of the equipment’s operating conditions play a crucial role.

As per the manual, there are preset conditions for temperatures and pressures, but if your actual system runs hotter (or production is being pushed a bit more), it is functioning outside the operating envelope.

The spec sheet tells you what the oil can do. Your operating conditions tell you what it must do.

Additionally, if your surroundings are harsh (close to the sea or in a corrosive environment, or in a non-ventilated area where heat can build up), these can place additional stress on the equipment. For these harsher conditions, a synthetic oil might be more appropriate than a mineral oil, albeit more expensive in terms of the initial investment.

The manual also specifies which tests/characteristics should be used to monitor the condition of the oil, namely: viscosity, particle count, water content, demulsibility, air release, foaming characteristics, RULER®, and MPC. Based on the performance of your current oil in the system, you can determine whether these values fluctuate toward the higher warning zones. This can also influence your decision about which oil to choose.

It’s not just about the right oil or one that aligns with OEM requirements. The selection should also be based on the environmental conditions of the oil and the equipment, and on whether the oil is suited to perform in these conditions. A mineral oil will not withstand the temperatures that a synthetic oil can for extended periods without degrading. Similarly, given the “right” conditions, synthetic oils can also degrade. By cross-examining your spec sheet, OEM manual, and actual conditions, you can determine the best-suited oil for your operations.

Common Modes of Failure

Regardless of the oil selected, common modes of failure can occur with every lubricant. These include: contamination, improper storage and handling practices, and environmental factors, as shown in Figure 4.

Figure 4: Common modes of failure for lubricants

Contamination can be defined as any foreign particle entering the system. This includes any gases, liquids, or solids. Especially when the lubricant system runs alongside the process side, process gases and liquids can leak into the oil. These contaminants can influence the oil’s degradation, leading to deposits or chemical reactions that break it down. Common process contaminants include ammonia or treated water.

The biggest threat to the right oil is often what gets added to it – whether it’s process contamination or the wrong oil during a top-up.

Another liquid that can contaminate oil is another oil. During top-ups, operators can add the wrong oil to the system, causing contamination and, depending on the oil, a possible shutdown. Adding motor oil to hydraulic oil can be catastrophic, as the additive packages work differently and the motor oil additives may counteract the hydraulic additives, removing them from the oil, leaving the asset open to wear and failure. Despite selecting the correct lubricant for your system, adding the wrong oil (mistakenly) will shorten its lifecycle and cause the asset to fail.

Bad storage and handling practices can also erode your oil, regardless of the oil you choose. Turbine and hydraulic oils are used in precise equipment. As such, they need to be clean and free of dirt or other contaminants. However, if oils are not stored correctly, contaminants can enter and contaminate the oil.

Simple techniques, such as transferring oil from larger storage containers (pails, drums, or totes) into smaller, more manageable containers (2-3 liters or less), can introduce contaminants into the oil if not done correctly. If oils are to be transferred to another storage container, the storage container must be clean. The transfer process should use clean hoses (not previously used for another lubricant) and be completed in a dust-free environment.

If you wouldn’t use a dirty needle for a blood transfusion, why would you use a dirty hose for an oil transfer?

The transfer of oils from one container to the next can be thought of as a blood transfusion. Would you use dirty needles or vials to transport the blood to be placed into another human? Similarly, oil can be likened to the equipment’s lifeblood and should be treated accordingly. Just as we observe sterile practices for blood transfusions, we should also observe similar types of practices for oil transfers.

Environmental and operational factors can also influence lubricant degradation. As stated earlier, all lubricants can degrade over time under harsh conditions. The lubricant formulation largely influences this, as does whether it was blended to withstand those conditions.

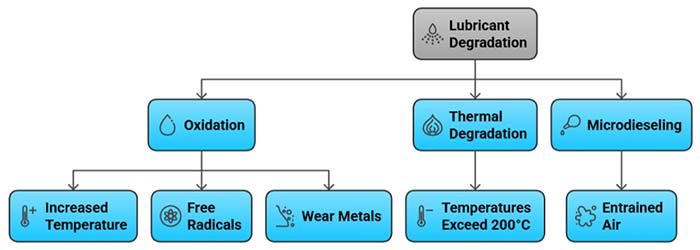

Oxidation can easily occur when temperatures increase, free radicals are present, or when wear metals are present. Thermal degradation occurs when the temperatures exceed 200°C. On the other hand, microdieseling occurs in the presence of entrained air, despite the lubricant used in the system, as shown in Figure 5.

Figure 5: Lubricant Degradation Processes

Any of these degradation mechanisms can occur regardless of the type of oil chosen. Hence, it is essential to remember that operational conditions and environmental factors can heavily influence oil degradation, even when the oil is appropriate for the system.

Role of Condition Monitoring

As mentioned earlier, choosing the right oil for the system is just one part of the puzzle. How do we know the oil is performing when it’s in the system? This is where condition monitoring can work hand in hand to help ensure that the oil does not fail the asset.

If a proper oil analysis program does not exist, operators will not know whether the oil is properly lubricating the asset. They will also not be aware of whether the oil is breaking down too quickly and failing to protect the asset. Oil analysis can also alert operators to signs of wear in the asset, so they can fix them before they turn into functional failures.

An oil analysis program that lives in a drawer protects assets about as well as no program at all.

There is also the possibility that an oil analysis program exists but is not top of mind, or that its results are put in a drawer. This can also cause the asset to fail even though the correct oil is being used. Apart from the aforementioned factors, if operators are not warned of the impending failure of the oil, this can result in production losses, increased downtime, and, in some extreme cases, the complete loss of the asset if it has failed beyond repair.

Incorrect sampling is another area in which the actual condition of the asset is not reported. Even with the correct oil used, if a sample is collected from a dead leg or an area that is not truly representative of the conditions inside the component, its actual condition will not be known. With incorrect data about the component, the asset can be misdiagnosed or treated for symptoms that do not exist, which can lead to its detriment.

Human and Organizational Factors

Not all failures occur at the equipment level; human and organizational factors can also cause the asset to fail even when the correct oil is used. If humans aren’t properly trained in oil sampling techniques or storage and handling practices, these can affect the asset’s functionality. We often forget that, at the heart of it all, lies the human factor, which is partially governed by the organization’s systems.

Training needs are an organizational factor that is often overlooked when considering how an asset can fail. However, if operators have not been trained in condition monitoring techniques, they will not be able to read oil analysis reports or take appropriate actions to protect the asset. Training can help bridge some competency gaps that directly impact asset performance.

It doesn’t matter what oil is in the system if no one is trained to monitor it – or motivated to care.

Culture is another factor swept under the rug. If the culture doesn’t exist to look after the assets, it doesn’t matter what type of oil is placed in the system; the asset will fail eventually. The performance of the asset does not only rely on using the correct oil. By implementing a culture of Asset ownership, where operators look after the asset and are accountable for its performance, assets are optimized to provide the functionality they should. This is one way to ensure the right oil is used to enable the assets’ performance.

Another area of concern is the documentation of maintenance procedures. If maintenance procedures are not adequately documented, someone new to the operation may not be aware of the correct practice. This, coupled with a lack of training, can spell disaster for the equipment. In these cases, even though the right oil was selected, the wrong practice or lack thereof can fail the asset.

Turning the “Right oil” into the “Right Outcome.”

As explained in this article, improper practices can jeopardize the asset’s health, even when the right oil is used. However, if all the right things align, we can have an asset that lasts for its expected lifetime or beyond.

This starts with selecting the right oil based on the application, environmental conditions, and OEM recommendations. If we follow this up with good storage and handling practices, proper condition-monitoring programs, documentation, and training, we can look toward a longer-lasting asset. The right oil enables reliability – but only disciplined practices deliver it.