The success of oil mist lubrication on a scale ranging from just one machine to 30 plant-wide oil mist systems serving 2,000 or more machines at a single site has been a matter of record since the mid-1960s.

Oil mist lubrication is a fully proven and superbly reliable technology.

Oil mist experts with access to many plants and reliability professionals with decades of applicable experience consider oil mist lubrication a fully proven and superbly reliable technology. They have become experts by learning from others, being inquisitive, and considering it their obligation to read books, articles, and conference proceedings on the subject matter.

None of these experts would find requesting or endorsing field trials plausible. Even today, field trials would add nothing to the existing knowledge on the subject. We mention this because the issue arises when uninformed persons call for field trials to prove that oil-mist lubrication is not just wishful thinking.

There was no justification for such demonstrations on the two known occasions when field trials were requested in the 35 years from 1986 until 2021. Perhaps a subcontractor attempted to turn experience-based technical advice into a “make work” project. Or it could have been a matter of “seeing is believing,” and the individuals making the “show me” request hoped they would not need to spend time reading.

Mature technologies like oil mist don’t require prototyping or proof of concept.

Whatever the case, it is inappropriate and wasteful to demand proof of concept and/or selection of beta sites for mature technologies such as oil-mist lubrication and oil-mist preservation. Hundreds of full-scale installations attest to its effectiveness and reliability. Mature technologies are the exact opposite of ideas or pursuits that warrant prototyping.

Storage Preservation: Where Field Trials Still Apply

The conventional methods of equipment preservation using several products discussed in Chapter 13 of our book, Optimized Equipment Lubrication, 2nd Edition (2021), and the suitability of utilizing those protection methods from a technical point of view is undisputed.

Competent manufacturers and vendors have continually improved such products. Their product-summary books and applicable brochures are informative and helpful. All available brochures have been carefully reviewed and, where needed, updated. These updates occasionally include clarifying or amplifying some of the recommendations issued by lube marketers when they align with the field experience of experts.

Today, lubricant technology is accessible worldwide. Accordingly, the recommendations and summaries of major U.S. providers of industrial lubrication could probably be joined by similar summaries available in electronic form from providers in other parts of the world.

Clarifying Deliverables in Lubrication Projects

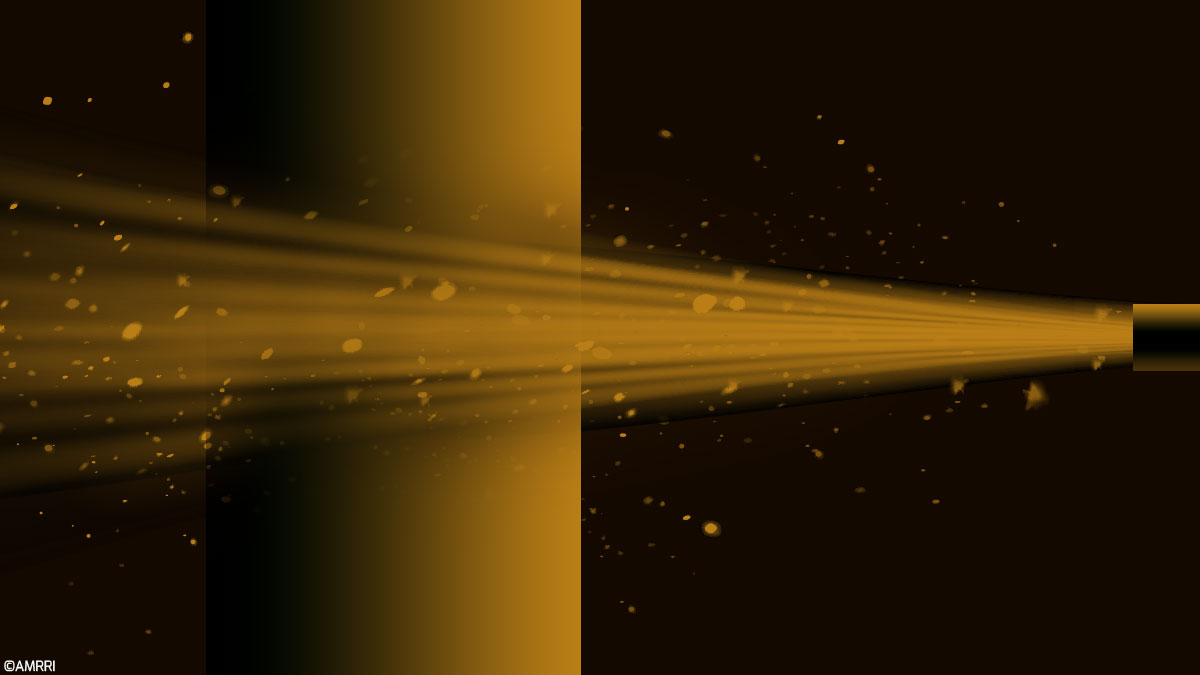

Expert providers of oil-mist lubrication and other preservation technologies usually have access to transparent polycarbonate or plexiglass (acrylic) demonstration models. For example, a transparent bearing housing replica equipped with ball bearings and a steel shaft is an ideal visualization tool. Mechanics, operators, supervisors, and managers can readily observe oil mist in operation.

Generally, expert providers agree to develop, sign, and adhere to contract clauses showing machine interiors in the “as-received” versus the “as removed from storage” condition.

The provider would have a service contract with the client and be able to monitor the storage yard, quality of instrument air supply, adequacy of lubricant, and so forth. The contract terms may include corrosion-monitoring details and an up-front definition of remedies.

Takeaways for Smarter Lubrication Practices

What have we learned here? Best practices do not involve reinventing the wheel. However, they require familiarization with the steps and procedures that have allowed the competition to prosper.

Best practices don’t reinvent the wheel—they use proven solutions.

Demonstrations, videos, and/or scale models may facilitate familiarization with best practices. Such items are often available at minimal cost. Some can be purchased, others rented or leased.

However, when it comes to oil-mist technology, which has been successful for decades at well over 3,000 plant sites worldwide, field trials proving that it works (in-plant “proof of concept”) are never justified.

On the other hand, in-plant demonstrations showing operators how oil mist works are part of an intelligent training routine that makes sense.