Over the years, the one thing that has always struck me is how few reliability teams work with their counterparts in the Health and Safety and Environmental departments.

Linking Lubrication to ESG and Sustainability Goals

To quote the guru, Ron Moore, in his article, “A Reliable Plant – Good for Personal and Process Safety”:

Compelling data from operating plants has been provided to demonstrate that “a reliable plant is a safe plant, is a cost-effective plant, is an environmentally friendly plant.” The reverse was also shown, that is, an unreliable plant is less safe, more costly, and less environmentally friendly.

This is something that I trot out in every training session, whether it be an awareness class or a certification preparation class. Yet I sense there is still a “them and us” attitude between reliability engineers and their colleagues on the other side, and vice versa.

I want to focus on the environmental benefits in this article as they are fundamental to sustainability. A quick trawl of LinkedIn and, of course, a rapid scan of most corporate mission statements, one is bound to see Sustainability mentioned. Just how serious are we about this, or is it simply paying lip service to a perceived wish from the public at large?

I believe that the majority of the general public is concerned about the environment and the impact that it may have, and hence the proliferation of electric cars. I believe companies are also concerned, perhaps more so as a result of the penalty to comply and the cost in terms of environmental damage and the punitive costs that result.

So, if companies are serious about sustainability, how can lubrication assist in the challenge for a more sustainable operation?

Why Reliability and Lubrication Are Sustainability Cornerstones

Let’s start with the issue of reliability. Lubrication is, call it what you will, a cornerstone, a foundation block, or a core element of reliability. Without a successful lubrication strategy based on best practice, reliability is doomed to mediocrity at best.

- When equipment runs smoothly, without unnecessary stops and breakdowns, then the emissions are lessened, and this also avoids the energy spikes that a start-up generates.

- With longer-lasting components and machines resulting from improved reliability, fewer emissions are created by re-manufacturing and shipping of the replacement parts and units.

- With longer lubricant life, there is less risk of spillages and leakages, and reduced deliveries to the site.

- With all the above, the strain on natural resources is diminished.

That, in a nutshell, is lubrication-focused sustainability.

Essentially, any business seeking to be more sustainable needs to put an effective lubrication strategy in place as part of its reliability drive.

However, that isn’t all of it. What else can be done to achieve greater levels of sustainability that also aid in the reduction of costs?

Reduction of costs? Surely sustainability costs? For once, we have a win-win scenario!

Let’s start by looking at some of the simpler aspects.

Simple Lubrication Changes That Deliver Big Sustainability Gains

The first option is to switch from spin-on oil filters to simply replacing the elements. A spin-on filter requires an element, as well as a core support tube and a housing, the latter two typically being of metal. On disposal, this is a larger, heavier unit needing specialised disposal owing to the oil contamination.

However, going back to the traditional idea of a removable housing, with the core support tube as part of the filter head, then we have only the element to dispose. This is something that the automotive industry has returned to, with all new cars now typically just needing the element replaced. Here’s the win-win: less damage to the environment and cheaper element replacements.

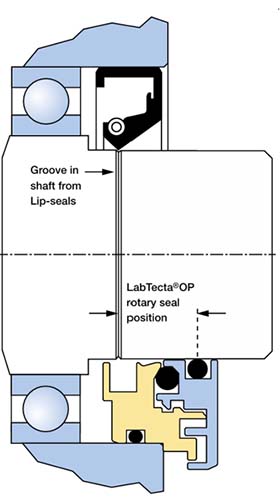

Labyrinth or non-contact seals versus the elastomer lip seal are another opportunity, particularly with process pumps with significantly higher shaft speeds. In addition to providing better sealing and reducing contamination ingress, the elastomer lip’s rubbing contacts cause less damage to the shaft, resulting in reduced friction and wasted power.

However, work by Heinz Bloch showed that while the superior seals are more expensive, the life-cycle cost was still significantly less than that of the simple elastomer lip seal—another win-win scenario for the environment and the profits.

Image from AESSEAL

Reducing Waste and Costs Through Smarter Lubricant Handling

Buying lubricants in larger volume containers is a further opportunity for win-win.

Going back to the mid-1990s, I recall many companies transitioning from buying lubricants in the 208L drums to buying in smaller 20L and 25L pails. Similarly, grease transitioned from the 20kg and 25kg kegs to the 400g plastic tubes. Understandably, this was partly a move to safer handling by having smaller packaging without the need for the handling equipment that heavy (more than 180kg) oil drums required, whilst 400g tubes of grease meant there was no longer the need to hand pack grease guns.

So why transition back to the older, less safe ways? Again, sustainability, yet with a win-win situation.

In researching pricing, it is often the case that for a container of fifty times the quantity of grease, the cost is only ten times more than that of the 400g tube. With oil, the proportionate volume differential from 20L to 208L to 1000L (ten times and 50 times, respectively) is eight times and thirty-six times, respectively. In my experience, buyers are always looking for the lowest price on lubricants!

Apart from the costs, think of the disposal issues associated with fifty plastic tubes compared to one metal pail. A further issue I find with the 20L and 25L pails, and even the smaller 400g tubes of grease, is the amount of waste. Volumes of 1L or more of new oil are often disposed of as the pail is near empty, and some remaining new grease is often discarded in the 400g tubes, which, over time and a reasonable throughput of these small containers, adds up to a considerable cost and impact on the environment.

Balancing Bulk Purchasing With Safe Handling Practices

But what about the handling issues? For many sites, such volumes are deemed unnecessary due to the numerous small-volume sumps. The volume of grease used is considered so low that it is not worth the larger volumes, especially given the health and safety risks associated with manual packing of grease guns, as well as the added contamination.

There’s an easy solution to these problems that addresses the issue of both safety and the environment, albeit at a small price of an investment. Frankly, though, these would be part of any best practice strategy in any case, but it is useful to justify the installation by linking the safety and sustainability aspects to the reliability needs.

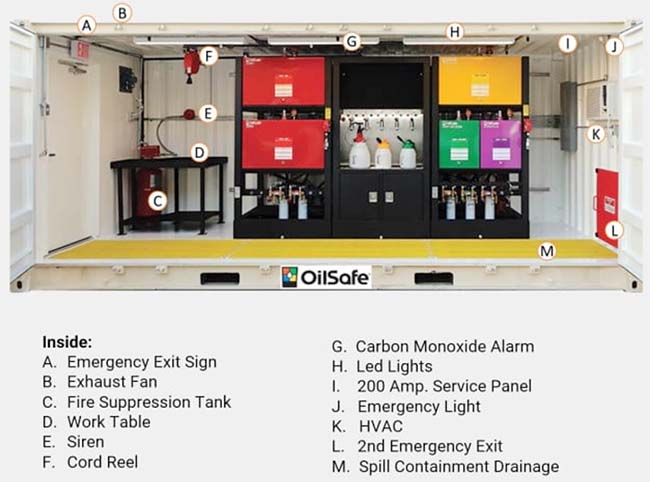

For the oils, the automated tank units allow for oil to be purchased in the 208L drums with dispensing into the smaller sealable and refillable containers. This will require the use of appropriate handling equipment for the movement of the drums.

Images from Enluse/OilSafe

For the grease, the cleanest way to fill the grease, with caution, is to use a drum pump. Most large containers of grease get left open and become contaminated, whereas using this method eliminates that problem. Fit a grease nipple to the gun in place of the vent, and then backfill the gun via a pump fitted to the larger 20/25kg pail.

Do not over-pressurize while filling!

Just from some of the examples above, it can be seen that aspects of lubrication can contribute significantly to reducing waste as well as cost. However, let’s keep in mind that irrespective of these, a reliable plant is a sustainable plant. Any company pushing its sustainability agenda should start with reliability.