Hydraulic systems are used to transmit force from one point to another via a fluid. This fluid is usually hydraulic oil, and the concept is based on Pascal’s law. Hydraulics are present in nearly all industries and play a critical role in enhancing operational efficiency. In this article, we will take a deep dive into hydraulic oils and explore them in more detail.

What is Hydraulic Oil?

One of the primary functions of hydraulic oil is to transmit power or energy. However, this is not its only function. Some of its primary functions include:

- Transferring pressure and motion energy

- Transferring forces and moments when used as a lubricant

- Minimization of wear to sliding surfaces under boundary friction conditions

- Minimization of friction

- Protection of components against corrosion (ferrous and non-ferrous metals)

- Dissipation of heat

- Suitability for a wide range of temperatures, good viscosity-temperature behavior

- Prolonging the life of machinery

However, hydraulic oils also have secondary and tertiary functions.

Some of the secondary characteristics of hydraulic oils include high aging stability, good thermal stability, inertness to materials, compatibility with metals and elastomers, good air separation, low foaming, good filterability, good water release, good shear stability (in the case of non-Newtonian fluids), and more.

On the other hand, some of the tertiary characteristics include low evaporation due to low vapor pressure, toxicologically harmless, ecologically safe, and low flammability (fire resistance), all of which depend on how the fluid is formulated.

History of Hydraulic Oil

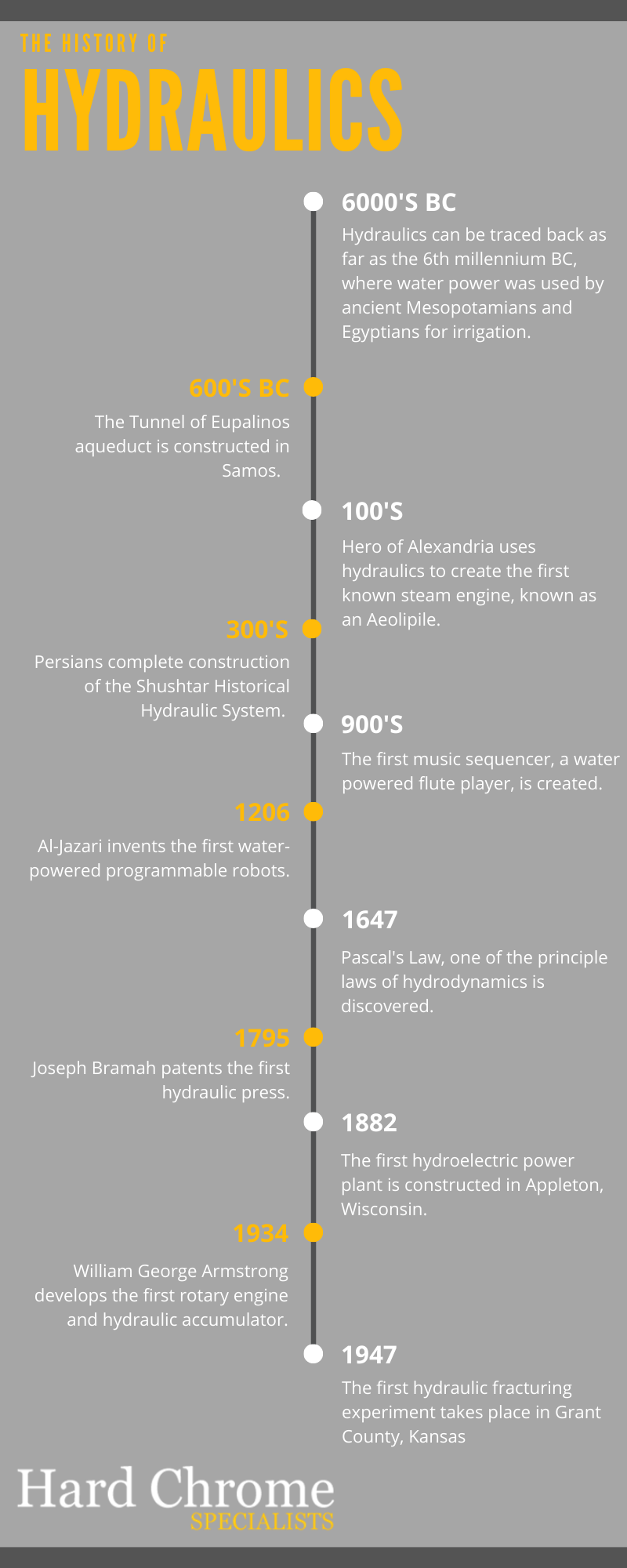

The principle of hydraulics has been around for a very long time. In fact, according to Hard Chrome Specialists, it may even date back to around 6000 BC, when ancient Mesopotamians and Egyptians used water for irrigation. Fast forward to the modern day, where hydraulics have been heavily influenced by Blaise Pascal, Joseph Bramah, Daniel Bernoulli, and William George Armstrong. A snapshot is shown in Figure 1 below.

Figure 1. History of Hydraulics as per Hard Chrome Specialists

Importance of Hydraulic Oil

Hydraulics forms part of the field of fluid technology, which can be further subdivided into hydrostatics and hydrodynamics.

For hydrostatic systems, the transfer of energy requires static pressure; hence, the pressure is high, but the flow rate is low. Fluids designed for these applications are known as hydraulic oils.

For hydrodynamic systems, the kinetic energy of the flowing fluid is utilized, resulting in low pressure but high flow rates. Fluids designed for these applications are known as power transmission oils.

As explained earlier, Pascal’s law forms the basis of hydraulics. Using the principle of the hydrostatic displacement machine, Pascal’s Law states that, “Pressure applied anywhere to a body of fluid causes a force to be transmitted equally in all directions. The force acts at right angles to any surface within or in contact with the fluid”.

Hydraulic systems utilize hydraulic oils to transmit power or energy to other applications, making them the second most crucial group of oils, after engine oils, due to their widespread use. As a result of their primary application, they can help save energy, reduce maintenance intervals and wear, increase machine life, and overall provide users with significant savings.

Types of Hydraulic Oil

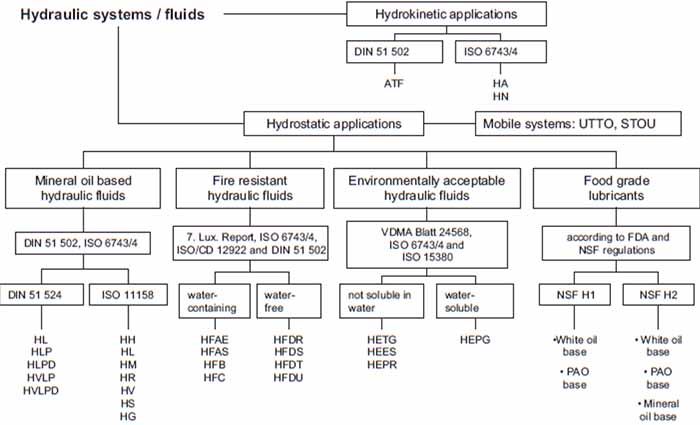

There are many types of hydraulic oils due to the number of applications in which hydraulics are used. Generally, they can be classified as shown in Figure 2 below.

Figure 2. Classification of hydraulic fluids – overview, adapted from (Mang & Dresel, 2007)

As can be seen above, there isn’t just one type of hydraulic oil. Depending on the application, different standards are associated with each type. The two main groups are hydrostatic applications and hydrodynamic/hydrokinetic applications.

The hydrodynamic applications mainly include ATFs (Automatic Transmission Fluids).

On the other hand, for the hydrostatic applications, the mobile systems refer to UTTO (Universal Tractor Transmission Oil) and STUO (Super Tractor Universal Oil).

These hydrostatic applications can be further categorized into mineral oil-based hydraulic fluids, fire-resistant hydraulic fluids, environmentally acceptable hydraulic fluids, and food-grade lubricants. Each of these has its associated standards and regulations.

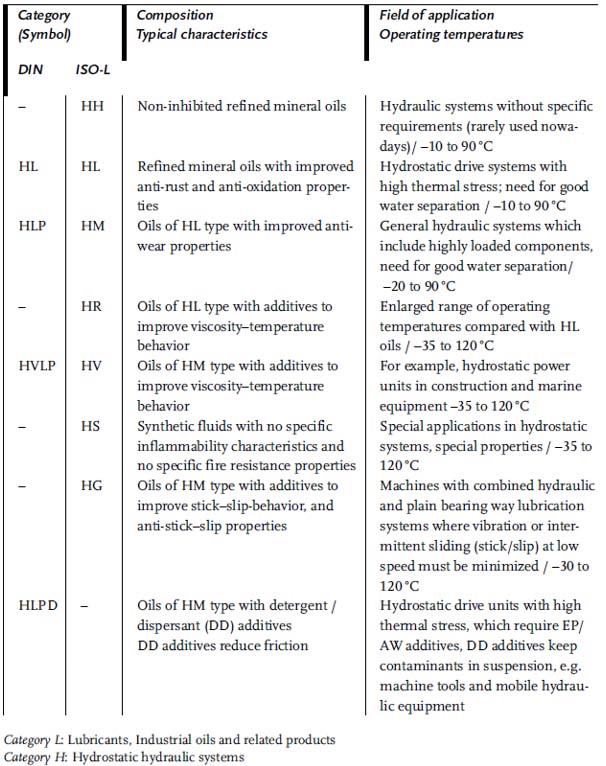

For Mineral oil-based hydraulic fluids, there are different classifications, as shown in Figure 3 below.

Figure 3. Classifications of mineral-based hydraulic oils adapted from (Mang & Dresel, 2007)

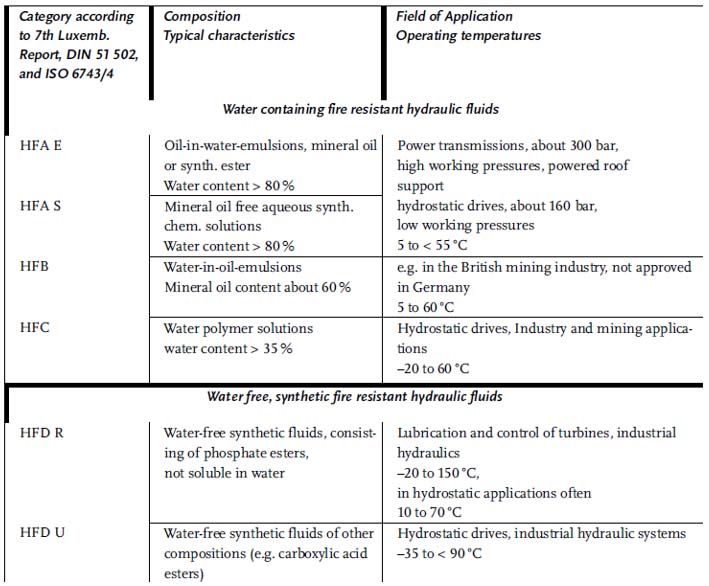

For fire-resistant oils, their classifications include those shown in Figure 4 below.

Figure 4. Fire-resistant hydraulic classifications adapted from (Mang & Dresel, 2007)

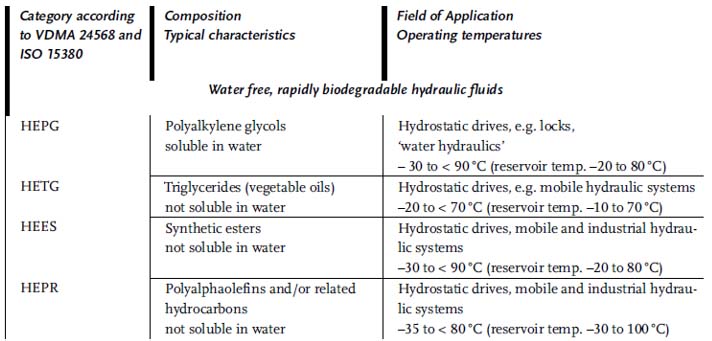

For Environmentally Acceptable lubricants (particularly water-free, rapidly biodegradable hydraulic fluids), their classifications are shown in Figure 5 below.

Figure 5. Environmentally Acceptable Lubricants adapted from (Mang & Dresel, 2007)

For food-grade lubricants, their classifications include:

- NSF H1 – These are colorless, odorless, tasteless, non-toxic, and are certified for incidental contact with food

- NSF H2 – These are lubricants that can be used in food processing, but only where there is no contact with food.

(Other categories of NSF grades exist, but these do not apply directly to hydraulic oils.)

Chemical Composition of Hydraulic Oil

Chemical Composition of Hydraulic Oil

Due to the unique nature of hydraulic oils, they are formulated differently from other oils. Typically, it follows the regular oil formulation of Base oil + additive to give the finished product. However, many various combinations occur depending on the application for which it is being formulated.

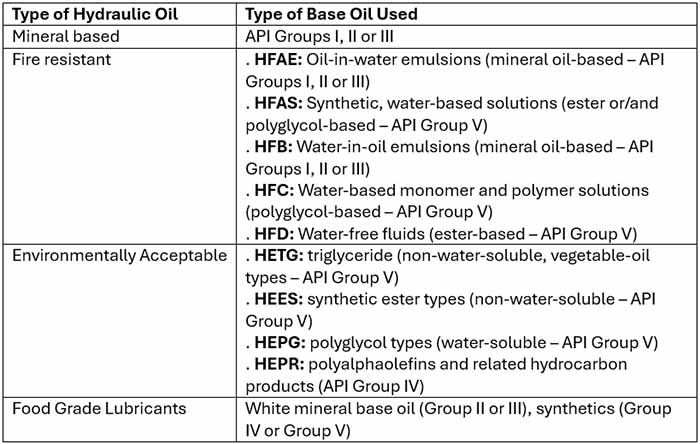

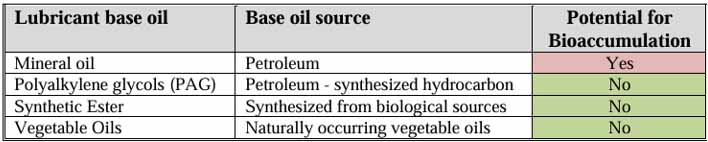

Base Oils Used in Hydraulic Oil

Similar to other oils, any base oil can be used to create hydraulic oils. However, depending on the application in which it is being used, the type of base oil will differ. The following table gives a summary of the types of base oils used for various hydraulic oils.

Table 1. Summary of the types of base oils used in various hydraulic oils

Additives in Hydraulic Oil

Generally, hydraulic oils are composed of 95-98% base oil and roughly 2-5% additives. One major distinction of hydraulic oils is that they can be either zinc-containing or zinc-free (also known as ashless). The ZnDTP molecule is responsible for antiwear properties, but this does not mean that zinc-free oils do not contain some form of antiwear additive.

Zinc-free oils are formulated with no zinc and minimal concentrations of phosphorus and sulphur. These zinc-free oils are formulated for special applications where the presence of zinc could react negatively with the environment, such as equipment containing mixed metals or silver.

There are other additives used for hydraulic oils, which are classified as either surface-active additives or base-oil-active additives.

Surface-active additives include steel/iron corrosion inhibitors, rust inhibitors, metal deactivators, wear inhibitors, friction modifiers, and detergents or dispersants.

Base active additives include: antioxidants, defoamers, VI Improvers, and pour point improvers.

Common Contaminants in Hydraulic Oil

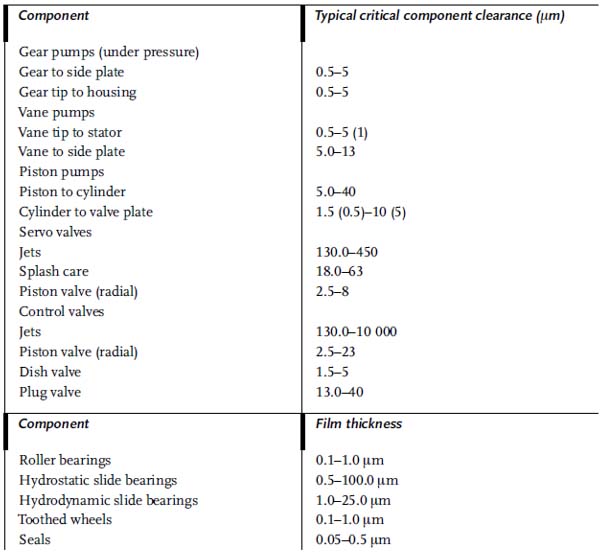

Hydraulic systems are known for very tight clearances. As such, any form of physical contaminant can easily clog the valves or lines, leading to system failure. Keeping hydraulic oils clean is of paramount importance. Figure 6 illustrates typical clearances for hydraulic components, as well as the film thickness for various components.

Figure 6: Hydraulic component clearances and film thickness adapted from (Mang & Dresel, 2007)

The contaminants that exist in hydraulic systems can be either internally generated or externally consumed. Typically, dirt from external sources or metal wear (internally generated) form the major contaminants for hydraulic oils.

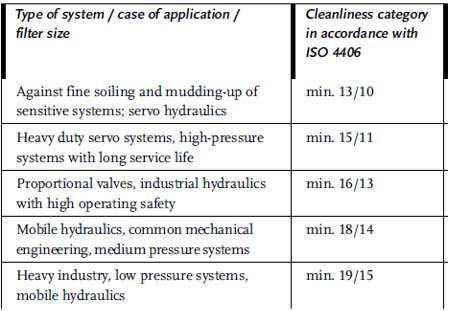

However, they are also susceptible to gaseous or liquid contaminants that can enter the system through system processes or external factors during oil handling before it enters the system. Figure 7 shows some cleanliness categories for various components.

Figure 7. Cleanliness categories for various components adapted from (Mang & Dresel, 2007)

Testing and Analyzing Hydraulic Oil Composition

There are several basic tests that should be used to determine the condition and health of hydraulic oils. These include:

- Viscosity (ASTM D445) – Generally, if this value falls below or above10-15%, there is cause for concern. Any increase in viscosity (outside of the system limits) can lead to the system experiencing higher pressures. Conversely, any decrease in viscosity outside of the limits will not allow for the full transfer of power through the fluid.

- Water content (ASTM D6304) – Too much water in a system is always a bad thing (except in a swimming pool). In particular, if the water content starts trending upwards of 500 ppm, the source of water ingression should be found and eliminated at once. This can hinder the transmission of power in the system, making it less efficient.

- Presence of wear metals (ASTM D5185-05) – These values will differ depending on the system in which the hydraulic oil is being operated. It would be a good idea to contact the OEM about the limits for the wear metals for your system to ensure that no irregular wear is occurring. The presence of these wear metals may also act as catalysts for other reactions, potentially leading to the degradation of the oil.

- Particle Count (ISO 4406) – This also depends on your system, as varying levels of cleanliness are typically aligned with different systems. However, with hydraulic systems, there is usually some guidance on the tolerance levels. The presence of these particles can hamper the transmission of power in the system or block clearances.

Specialty tests for hydraulic oils also exist. These include tests for monitoring antiwear and extreme pressure, foaming, or oxidation stability characteristics of the oil. For determining the antiwear or extreme pressure properties, tests such as the Vickers Vane pump test, 4 Ball test, and FZG rating test can be used.

Properties and Characteristics of Hydraulic Oil

Hydraulic oils must be able to withstand particular conditions and still perform their primary function of transferring power from one point to another. As such, they have characteristics that make them unique from regular oils.

Viscosity of Hydraulic Oil

The viscosity of an oil is one of the most essential characteristics, especially for hydraulic oils, as they must transfer power. As such, the viscosity-temperature characteristic of hydraulic oils is also critical. As the temperature of the oil increases, its viscosity decreases (or becomes thinner). Similarly, if the temperature of the oil decreases, its viscosity will increase (or become thicker).

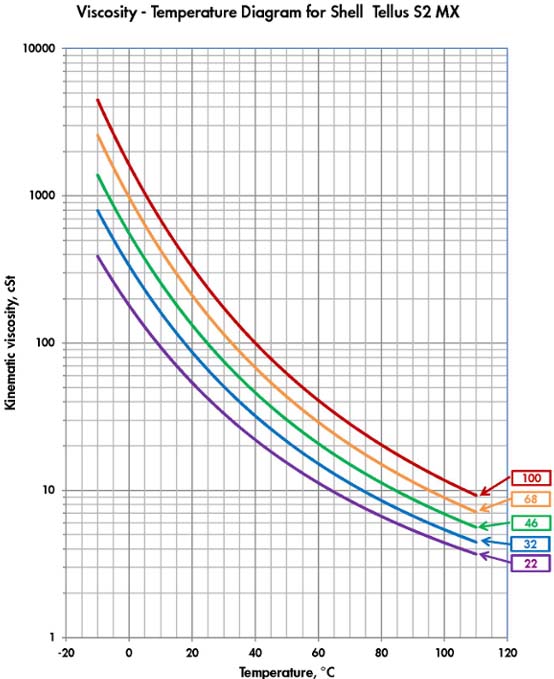

For hydraulic oils, some manufacturers plot their viscosity against temperature to help customers determine the ideal viscosity for their system based on the system’s operational temperatures. Figure 8 shows a chart for Shell Tellus S2MX, illustrating the varying viscosities as the temperature changes.

Choosing the wrong viscosity can cripple power transmission before the system even starts.

For instance, if the system is running at 60°C and the oil needs to have a viscosity of 30cSt, then an ISO VG 68 would be the most ideal oil. However, if the system is running at 40°C, and the viscosity needs to be 30cSt, then an ISO 46 oil would be more appropriate.

The relationship between viscosity and temperature is known as the viscosity index. For hydraulic oils, the higher the viscosity index, the less susceptible the viscosity is to changes in temperature. As a reference, mineral base oils have a natural viscosity index (VI) of 95-100, while synthetic ester-based base oils have a VI of 140-180, and polyglycols have a natural VI of 180-200.

Figure 8. Viscosity-Temperature chart for Shell Tellus S2MX oils

Oxidation and Thermal Stability

The TOST (Turbine Oil Oxidation Stability Test) is usually used to determine the oxidation stability of an oil. Although the test name mentions “turbines”, it can also be applied to hydraulic oils.

Another test that can be used to evaluate whether oxidation has taken place or not would be the RULER® test, which quantifies the remaining antioxidants in the oil. Overall, determining the oxidation and thermal stability of the oil provides the user with an average estimate of the oil’s life expectancy when subjected to environmental extremes.

Foam and Air Release Properties

Due to the operating environment of hydraulic oils, air tends to become trapped in them. This can become a problem as it can easily lead to cavitation inside pumps (the most prevalent form of wear for these systems). Therefore, hydraulic oils must have good air release and anti-foaming properties.

Good air release allows the dissolved or trapped air to coagulate and rise to the surface, where it can then be dissipated. This is where the issue of foam “arises” as it further impedes the oil’s ability to form a full wedge between the two surfaces in any system.

Demulsibility and Water Content

Demulsibility refers to the ability of oil to repel water. Typically, hydraulic oils are designed to operate in environments with some water or high humidity, where water can easily enter the oil.

For hydraulic oils containing detergents or dispersants (DD), fluids (such as water) or other fine contaminants are usually held in suspension. Therefore, the demulsibility test, in which water and oil are mixed and then allowed to separate, will not be effective in determining the water separation characteristic of these hydraulic oils. Filtration should be used for these DD oils, which become contaminated with water.

Water in hydraulic oil isn’t harmless — it’s a silent trigger for failure.

On the other hand, for those oils that do not contain detergents or dispersants, the demulsibility test (ASTM D1401) can be performed. For this test, equal parts of oil and water are mixed at a specific temperature to create an emulsion and then allowed to separate. The amount of oil, water, and emulsion is recorded at 5-minute intervals.

If the viscosity of the oil is less than 90 cSt and there is 3 mL of emulsion or less after 30 minutes, the oil is acceptable. If the oil has a viscosity greater than 90cSt, the result is taken at the end of 60 minutes (if the value of the emulsion is less than 3 mL, it is acceptable). The results are usually recorded in the format: mL oil / mL water / mL emulsion (time recorded in minutes).

Corrosion Protection

Many hydraulic systems contain copper metals, brass, or bronze, especially in cooling systems, pumps, bearing elements, or guides. Therefore, hydraulic oils must be resistant to copper corrosion, as this could compromise the entire system. One such test, which can be used to identify the corrosivity of these oils, is the Copper Strip Corrosion test.

In this test, the copper strip is placed in hydraulic oil for a typical duration of 3 hours at 100°C. The results can be quantified based on the level of discoloration, which correlates with the degree of corrosion.

A similar type of test can also be done with steel / ferrous corrosion. In this case, the oil is mixed with distilled water or artificial seawater and stirred constantly for 24 hours at 60°C while the steel rod is submerged in the mixture. Afterwards, the steel rod is examined for corrosion and allocated ratings accordingly.

Maintenance and Testing of Hydraulic Oil

Keeping hydraulic oils clean is critical to their operation, as any contaminant can interfere with the amount of power that they can transmit. These oils are also subjected to harsh conditions, so monitoring their quality will help to ensure that they provide the maximum efficiency for the system in which they are working.

Importance of Regular Maintenance

Hydraulic oil systems are notoriously known for leaks. Sometimes this revolves around failed seals or the improper use of material for the actual system, which cannot tolerate the existing conditions. Despite the root cause of the leak, it is essential to perform regular inspections on hydraulic equipment, as a leak can lead to a loss of power, potentially delaying or causing work in progress to come to an unexpected halt.

Hydraulic leaks are also detrimental to the environment, particularly if they seep into the ground or waterways. Hence, it is crucial to perform regular checks and maintenance on hydraulic systems to prevent harm to the environment.

A single unnoticed hydraulic leak can halt production and harm the environment.

Some other factors to consider regarding the maintenance of hydraulic fluids include maintaining the temperature and oil levels at the expected system values, as well as keeping the hydraulic oil clean to avoid contaminants.

Users should also be performing routine oil analysis (to catch any changes to the oil, which may lead to detrimental effects). Additionally, routine inspections can include checking noise levels, shock loads, filtration, vibration, leakage, fluid odor, color, and the presence of foaming. These additional methods can prove beneficial for intercepting early failures.

Common Methods for Monitoring Hydraulic Oil Condition

When monitoring hydraulic oils, several key characteristics to pay attention to include viscosity, AN (Acid Number), Water content, the presence of wear metals, and contaminants.

Any change in viscosity can affect the transfer of power, while an increase in Acid Number (AN) can indicate the degradation of the oil. On the other hand, the presence of any contaminant can also impact the performance of the oil, possibly leading to its degradation while acting as a catalyst.

Alternatively, the presence of wear metals can also indicate that wear is occurring on the inside of the hydraulic equipment. It may initiate a physical maintenance check to determine the extent of the wear.

Steps for Changing Hydraulic Oil

When changing hydraulic oil, it is important to note the previous condition of the oil. If there is a high concentration of contaminants, the system should ideally be flushed before introducing a new batch of oil. This prevents the new oil from also becoming contaminated and degrading at an accelerated rate.

Additionally, some physical contaminants may have also become lodged in the tighter clearances. Hence, it is always a good idea to perform a flush on the system, ensuring that it is clean before a new batch of oil is used.

Proper Storage and Handling

Hydraulic oils must be clean, and depending on the system, they have very specific cleanliness requirements. As such, when storing hydraulic oils, special care should be taken to ensure that the rooms are clean, the decanting equipment is clean (free from dirt or other contaminants), and a filter cart is used when decanting new oil into a system. Hydraulic oils do not mix well with other oils, and dedicated systems or equipment are required for decanting these oils.

Troubleshooting Common Issues

One of the main issues with hydraulic oils is their susceptibility to contamination. Contaminants can be in the form of physical particles, liquids, or gases.

In the case of gases, this usually leads to cavitation (one very common challenge with hydraulic oils) or an increase in the presence of foam. Hydraulic oils can also become contaminated with water, which affects their ability to transfer the required amount of power.

If your pump sounds like marbles, air or cavitation is already stealing performance.

Typically, technicians have reported hearing the “sound of marbles” within pumps that are experiencing cavitation. In these cases, there is usually an air leak or air entering the system where it is not intended to. This can be an issue with the intake or suction part of the pump, where the oil levels are low enough to allow for air to enter the system and then become trapped. In these cases, a baffle plate can be placed inside the reservoir at a 60-degree angle to trap some of the air bubbles.

On the other hand, when water is present in the hydraulic oils, depending on the concentration, a vacuum dehydrator or regular filtration system can be used to help remove the water. Subsequently, for hydraulic oils that contain a high level of physical contaminants, a filtration system can also be used to help remove them from the system.

Selecting the Right Hydraulic Oil

Selecting the Right Hydraulic Oil

With numerous hydraulic oils available on the market, selecting the one that best suits your system can be a challenging task. Several factors should be considered when choosing the most suitable hydraulic oil.

Factors to Consider When Choosing Hydraulic Oil

As with many oils, the first set of factors to consider when selecting an oil are the operational limits of the system and the oil. Typically, OEMs can guide users accordingly in this area, as they pay attention to the operating temperatures, pressures of the system, as well as the required viscosity of the oil.

Next, they need to consider the environment in which they are working. Are there any possibilities of the oil entering waterways or the soil? In such cases, environmentally friendly lubricants should be used. They also need to determine if these oils will be exposed to harsher environmental conditions than regular ones. If this is the case, then they may consider utilizing synthetic oils instead of mineral oils.

Compatibility with Equipment and Seals

Most mineral hydraulic oils are compatible with seals and some metals. However, certain hydraulic oils are not. HFC fluids (Water polymer fire-resistant hydraulic fluids with water content >35%) react aggressively with tin and cadmium. As such, silicone rubber and Teflon are the materials utilized when these fluids are in use.

On the other hand, HFD fluids (water-free, synthetic fire-resistant hydraulic fluids) attack aluminum and aluminum alloys in the presence of friction stresses. Therefore, the only materials used with HFD oils are Viton and Teflon.

Due to the polar nature of environmentally friendly ester fluids, this causes significant swelling of conventional standard elastomers. On the other hand, Epikote and DD paints are resistant to HEPG (water-free, rapidly biodegradable polyalkylene glycols that are soluble in water), HFC, and HFD fluids to a certain extent. Therefore, the inside of tanks or other exposed surfaces should not be coated with these materials to avoid corrosion.

Environmental Regulations for Hydraulic Oil

Environmental lubricants are typically classified into three main categories:

Biodegradability – measure of the breakdown of a chemical (or chemical mixture) by microorganisms. This can be Primary (where there is a loss of one or more active groups that renders the compound inactive regarding that function) or Ultimate biodegradation (also known as mineralization, where the chemical compound is converted to carbon dioxide, water, and mineral salts).

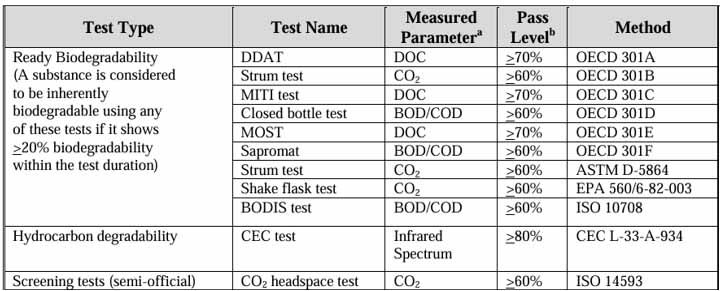

Two additional operational properties that define biodegradability are inherently biodegradable (showing evidence of biodegradability in any test for biodegradability) and readily biodegradable (where a fraction of the compound is ultimately biodegradable within a specific time frame, as specified by a test method). Figure 9 shows a table of internationally standardized test methods for measuring biodegradability.

Figure 9. Internationally Standardized Test Methods for Measuring Biodegradability as per United States EPA5

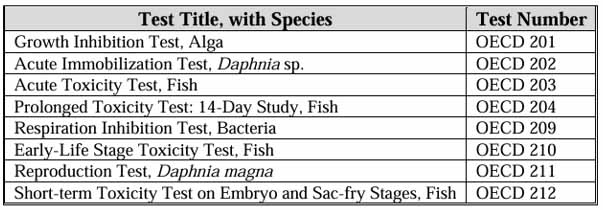

Aquatic Toxicity – This refers to the effects of a chemical on organisms that live in water and is determined using organisms representing three trophic levels: algae or plants (primary producers), Invertebrates (primary consumers or secondary producers), and vertebrates (secondary consumers).

Acute toxicity is determined by exposing fish to a series of concentrations of a chemical over a short period. The concentration that is lethal to 50% of the test fish is calculated and expressed as the LC50 value.

On the other hand, Chronic Toxicity covers a longer exposure time. It examines the effects on hatching, growth, and survival to determine the NOEC (No Observed Effect Concentration) values, LOEC (Lowest Observed Effect Concentration), or ECx values, where x is a percentage and the concentration of a chemical at which that percentage of the population shows some effect.

As seen in Figure 10, this is the list of OECD (Organization for Economic Co-operation and Development) Aquatic Toxicity Tests.

Figure 10. OECD Aquatic Toxicity Tests as per United States EPA

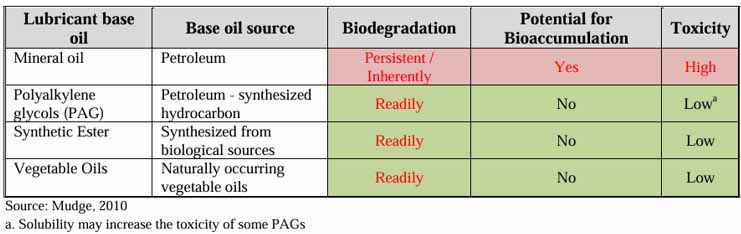

Bioaccumulation – this refers to the accumulation of chemicals within the tissues of an organism over time. Depending on the degradation rate of the chemical, this can lead to a buildup in the organism over time, ultimately resulting in adverse biological effects. The bioaccumulation potential of a compound is directly related to its water solubility. Figure 11 presents a summary of the bioaccumulation potential by base oil type.

Figure 11. Summary of Bioaccumulation potential by Base oil Types as per United States EPA5

Overall, when investigating the environmentally acceptable properties of lubricants, we can compare their behavior based on their base oil type, as shown in Figure 12 below.

Figure 12. Comparative Environmental Behavior of Lubricants by Base Oil Type as per United States EPA5

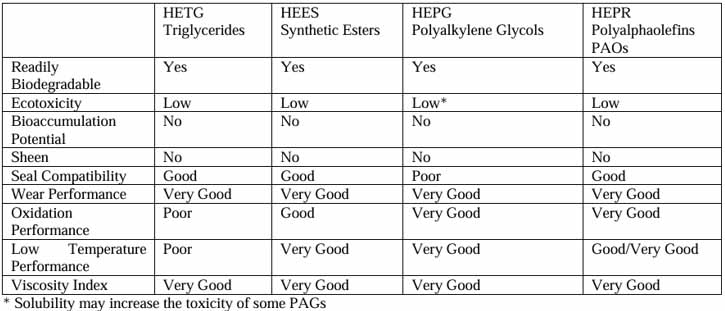

Additionally, a comparison of their features by type is illustrated in Figure 13.

Figure 13. Comparison of EAL types and features as per Houston

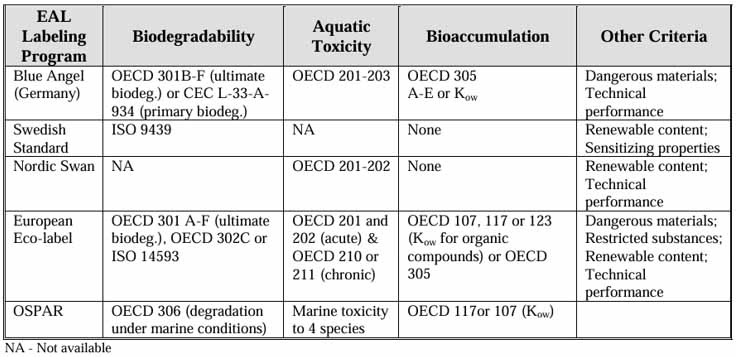

Several labelling programs provide guidance for EALS. These are summarized below in Figure 14.

Figure 14. Comparison of EAL Labelling Programs as per United States EPA

Tips for Storing and Disposing of Hydraulic Oil

Hydraulic oils are easily contaminated, particularly during storage and handling. Due to the tight clearances in hydraulic systems and their function of transmitting power, any contaminant can cause an issue with the system’s efficiency. As such, it is crucial to store and dispose of these oils properly.

Every ounce of contamination prevented during storage saves hours of troubleshooting later.

Proper storage of hydraulic oils includes keeping the containers closed and protected from the elements, as this prevents dirt particles from entering easily. These oils should not be stored in an area that is not covered or exposed to the elements, as this increases the risk of contamination. For any oil that is decanted into smaller containers, filters should be used during decanting (into a clean container) and upon decanting into the equipment to minimize the transfer of particles from the outside.

When hydraulic oil reaches the end of its life, it must be disposed of properly. In different countries, various rules and regulations govern this disposal. In many countries, a certificate of custody and chain of transfer is required when moving used hydraulic oils from the equipment site to the site where they are disposed of. Some waste oil removal companies ask that the hydraulic oils be separated from other oils, especially in cases where these will be re-refined to create new oils.

Global Market Size and Growth Projections

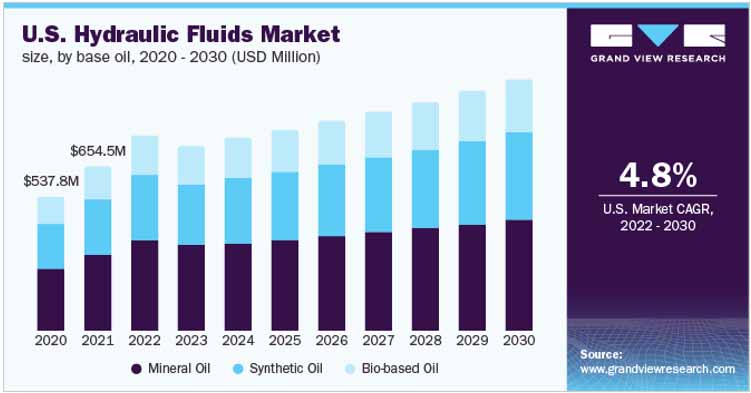

In 2021, the global size of the hydraulic fluid market was $7.6 billion, with a projected compound annual growth rate (CAGR) of 5.2% from 2022 to 2030. On the other hand, in 2021, the US hydraulic fluids market was valued at $654.5 million, as shown in Figure 15 below. They have an estimated compound annual growth rate (CAGR) of 4.8% from 2022 to 2030.

Figure 15. US Hydraulic Fluids Market by size and base oil type as per Grand View Research

Key Drivers and Challenges in the Market

An increase in construction due to greater global demand for infrastructure is noted as one of the key factors driving the demand for hydraulic fluids. Previously, during the pandemic in 2020, there were supply chain issues that affected the delivery of base oils to many markets. Additionally, the Russia-Ukraine war has also led to supply shortages, disrupting the regular market demand.

Regional and Industry-specific Trends in Hydraulic Oil Consumption

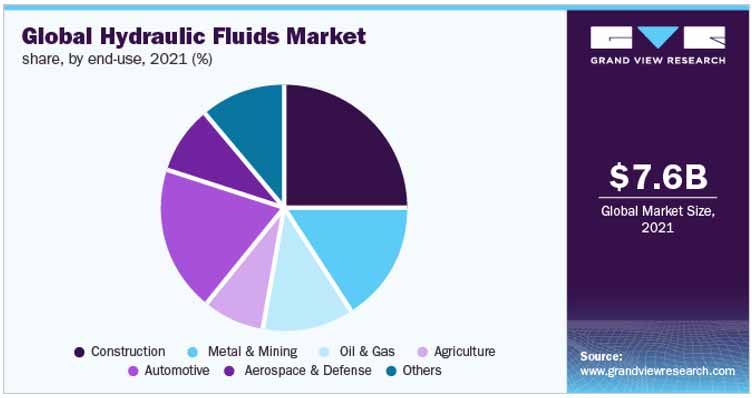

While the global hydraulic fluid market size was $7.6B in 2021, the most prevalent sector was construction (25.3%) as seen in Figure 16 below. As initially noted, the construction sector has seen a significant increase, but this should not distract from the prevalence of hydraulics in many other industries, including metal and mining, oil and gas, Agriculture, Automotive, aerospace, and defense, to name a few.

Figure 16. Global Hydraulic Market by sector as per Grand View Research

Emerging Technologies and Their Impact on the Market

As regulations regarding emissions and their impact on the environment become more stringent, we are seeing some movement towards EALs (Environmentally Acceptable Lubricants) and even synthetic hydraulic lubricants. Users are more aware of the environmental implications of hydraulic oils entering waterways and the overall CO2e associated with mineral oils compared to synthetic lubricants.

References

- Mang, T., & Dresel, W. (2007). Lubricants and Lubrication 2nd Edition. Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA.

- Hard Chrome Specialists. (2025, March 01). The History of Hydraulics. Retrieved from Hard Chrome Specialists: https://hcsplating.com/resources/hydraulic-systems-guide/history-of-hydraulics/

- National Lubricating Grease Institute. (2025, March 01). Grease Glossary H1/H2/H3/3H/HX1. Retrieved from National Lubricating Grease Institute: https://www.nlgi.org/grease-glossary/h1-h2-h3-3h-hx1/

- Totten, G. E. (2006). Handbook of Lubrication and Tribology Volume I Application and Maintenance Second Edition. Boca Raton: CRC Press, Taylor & Francis Group.

- United States Environmental Protection Agency, Office of Wastewater Management, Washington, DC 20460. (2011, November). Environmentally Acceptable Lubricants, EPA 800‐R‐11‐002. Retrieved from U.S. Environmental Protection Agency: https://www3.epa.gov/npdes/pubs/vgp_environmentally_acceptable_lubricants.pdf

- European Commssion. (2025, April 05). Aquatic toxicity. Retrieved from The Joint Research Centre: EU Science Hub: https://joint-research-centre.ec.europa.eu/projects-and-activities/reference-and-measurement/european-union-reference-laboratories/eu-reference-laboratory-alternatives-animal-testing-eurl-ecvam/alternative-methods-toxicity-testing/validated-test-methods-h

- Houston, M. (2015). New EPA Regulations for Environmentally Acceptable Lubricants and their effect on the dredging industry. Proceedings of Western Dredging Association and Texas A&M University Center for Dredging Studies’ “Dredging Summit and Expo 2015”, (pp. 384-391).

- Grand View Research. (2022). Hydraulic Fluids Market Size, Share & Trends Analysis Report By Base Oil (Mineral Oil, Synthetic Oil, Bio-based Oil), By End-use (Construction, Oil & Gas, Agriculture, Metal & Mining), By Region, And Segment Forecasts, 2022 – 2030. San Francisco: Grand View Research.