Solid Particle Cleanliness

In my previous articles, I have discussed how to achieve cleanliness within gearboxes and pumps, examining the entire aspect of solid particulate contamination ingress.

However, I was recently asked by an engineer following the above articles what a good target for cleanliness in these systems would be.

Cart Before the Horse

I probably should have written this article first, since the standard approach to improving reliability in terms of contamination control is as follows:

- Set targets for the contamination levels within the system.

- Undertake the steps to achieve the targets.

- Measure to ensure the targets are met.

Many programs initially focus on the 3rd step, believing that simply performing oil analysis will prevent failure. However, as I mentioned earlier in previous articles, this is akin to standing on the bathroom scales each morning and wondering why the hoped-for weight loss is not occurring. The simple act of measuring is not going to achieve the desired reliability, and as with weight watching, the oil analysis reflects the lubrication lifestyle of the plant.

How Much Should I Weigh?

As with any proactive lifestyle change, we need a target weight. Many years of medical research have shown that for a given height and gender, there are appropriate target weights. Though the effort put in now will not be apparent until later in life, and more to the point, it is not a simple matter of the more weight we lose, the longer we will live. Add variables to account for body shape and structure, etc., and it is not a simple calculation to set a target weight.

So What’s Involved in Setting a Target Cleanliness Level?

Probably the first aspect is the asset type, followed by the operating parameters, and finally, in my humble opinion, the desire to achieve the desired level of reliability.

Machine Type Influences

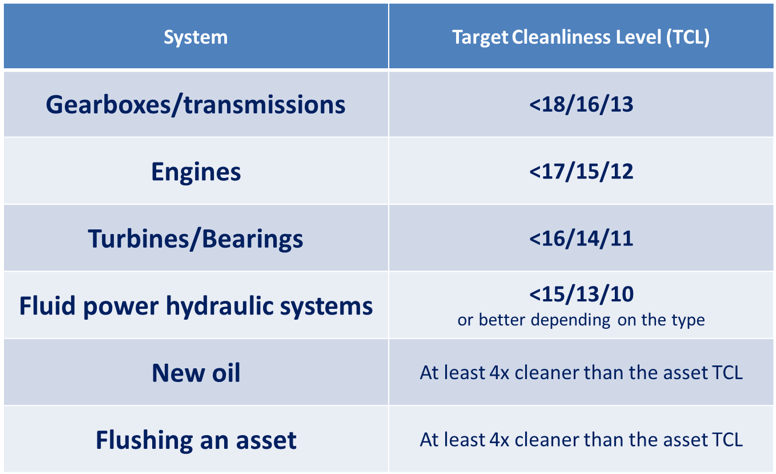

If we were to put the list of machine types in order from most to least tolerant of the solid particulate, then it would be:

Note that I have provided a generalized guide to the targets above. For those familiar with the ISO 4406:1999 Cleanliness Coding system for solid particles, hydraulics typically require a cleanliness level of around eight times cleaner than gearboxes.

There is a reason for this, and that is that when examining the clearances between components, complex hydraulic systems often feature valving with clearances of less than 5µm. In many cases, the high pressure and flow rate can lead to significant damage from solid particulates.

With gearboxes, however, gear teeth are generally hardened, and along with higher viscosity grades of lubricant, the solid particulate has a less significant impact on the wear rate.

Is a Cleanliness Target Necessary for a Gearbox?

Of course, it will still benefit from a reduction in wear rate and hence an increase in service life. That said, though, the implementation, or Step 2, must not come at a price greater than the financial gains incurred by the cleanliness control.

As with any reliability initiative, there must be a financial incentive to justify any technical improvements.

But Surely the OEM Will Advise What This Should Be?

Indeed, the Original Equipment Manufacturer may well give a guideline value. As mentioned, a reader contacted me, and he had approached several OEMs for clarification or had looked up the value in their documentation, which ranged from “not stated” to -/20/15 to 20/18/15 (ISO 4406:1999 solid particle reporting).

In my experience, OEM values are sufficient to avoid short-term and mid-term issues, but are inadequate concerning long-term reliability. The cynical may suggest that the OEM wants the user to replace parts, regardless. That said, there is a balance as an OEM does not want a reputation for poor reliability, either.

More specifically, a value stated in the OEM documentation may not account for the worst-case scenarios in terms of environmental conditions and operating conditions, either geographically or in terms of the business’s nature.

What About the Nature of the Business Or the Environment?

Let’s consider the geography; some locations will be more prone to dust ingress, such as those in or near desert environments. Conversely, the issue is less prevalent in damp environments, such as at sea. Concerning the industry, cement plants and mining/quarrying will again have higher levels of solid particulate than other industries.

Are There Other Factors to Consider When Adjusting the Target Cleanliness Level?

The cost justification has to be addressed, and therefore, other financial impacts include:

- Capital cost

- Repair costs

- Downtime costs

- Health and Safety risks

- Potential energy loss costs

The greater these are, the cleaner the oil needs to be.

Of course, to undertake a cost-benefit analysis, one must consider the additional costs of improved contamination control to achieve the target cleanliness levels, as well as the costs associated with monitoring these levels. Once that is known, we can then verify it against the potential savings. Worked from the above expenses.

To establish the possible savings, however, it is essential to look at the existing history and any recorded “Mean Time Between Repairs/Rebuilds/Failures”. Based on the research, we can then determine the potential life extension and calculate the resulting savings.

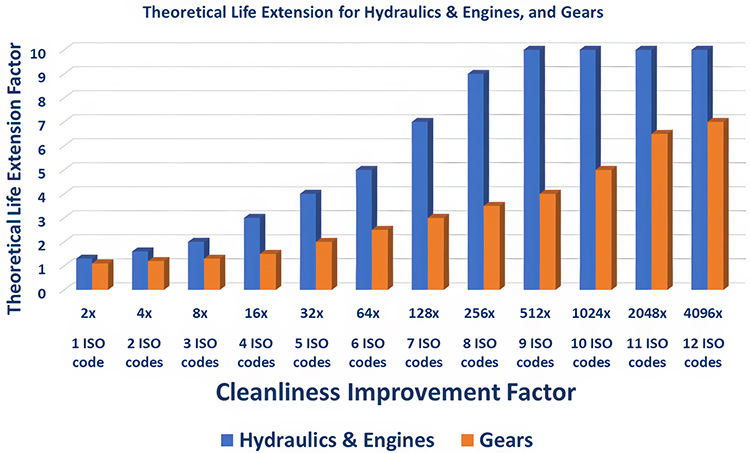

As with medical research, the Life Extension Tables serve as a useful guide to conservatively estimate potential gains. In the image below, for every 1 Range Number improvement in the ISO 4406:1999, we have an incremental increase in life. For gearboxes, this is not as great as with engines and hydraulics, but from around the 5 Range Numbers improvement (32 times cleaner), we start to see a significant gain.

Is It Worth It?

In my experience with gearboxes, few laboratories ever measure the solid particulate levels, with some suggesting that Ferrous Density is a better guide. There are various reasons for this, not least the risk of choking the Automatic Particle Counter with large gear wear debris.

Add in the fact that gear oil samples are often “wet,” leading to counting errors due to the thicker oil, and it is easy to see why most labs shy away. However, Ferrous Density analysis, such as PQ (Particle Quantifier) or WPC (Wear Particle Concentration), does not offer a predictive view of potential failure, as Ferrous Debris is the end result of the wear process, not the cause.

Consequently, using particle-trending techniques such as a mesh obscuration instrument or a microscope to establish the level will reveal that gearboxes are often significantly dirty. I have regularly seen ISO 26/23/21 on gear oils in some plants using mesh obscuration trending tools. Yet, with little effort, this has been reduced to as low as ISO 14/11/9.

That would result in a 12-range number gain, putting the potential life extension factor at around 7 times.

Even being conservative, a more than 6 Range Number improvement is more than double the life currently experienced.

In summary, a Cost-Benefit Analysis is essential to setting a target. Once the target is set, implement the improvements in contamination control and continually monitor to ensure the targets are being achieved.

- Determine the additional costs of filtration & Contamination Control

- Determine the Savings relating to the Life Extension

- Implement the 5-Year Cost-Benefit Analysis

- Seek Approvals

Targets must be optimized, feasible, and justifiable.