As with many things in lubrication, sometimes too much is as bad as too little.

This is certainly the case with filtration.

How Fine Is Too Fine for Your Oil Filter?

To answer that, we need to look at several factors.

First, let’s dispel a few myths about fine filtration and the perceived problems it can create.

“My oil analysis report showed a huge drop in additive elements after fitting finer filters.”

The perception here, of course, is that fitting the fine filters has removed much of the additive package. This is not the case. Before fitting the fine filters, a large quantity of solid material, including wear metals and depleted additives, would cling to these particulates. The spectral analysis will still detect these elements even though the additive is no longer of use.

After fitting the finer filters, much of this material is removed and no longer detected in the oil sample, allowing the proper level of fresh, available additive to be more clearly shown.

All of that said, there are several instances where caution is required regarding additive separation from barrier filtration. The following three additives are of most concern. In order of decreasing concern:

- Solid suspension EP additives such as Molybdenum Disulphide or graphite that can be up to 40µm in size. This is usually only applicable to gear oils, and in these instances, it is unlikely that filtration is even applied. More to the point, the lubricant supplier will usually provide warnings in this regard with these oils in the product data sheet.

- Defoamants work in various forms, but Silicon in its supersaturated state, as microscopic globules, can be up to 10µm in size. This is a concern with hydraulic systems, where there is a tendency to want the finest filter possible.

- Viscosity Index Improvers swell when subject to the oil warming and, as such, can potentially be caught in the filter. However, being soft in nature, they do typically make their way through.

Generally, additives are much more at risk from decomposition driven by water, heat, oxygen, and reactive solids such as wear metals, or from poor storage in extreme ambient temperatures over longer periods.

“Fitting finer filters will simply result in shorter element life, and the cost will be significantly higher.”

The assumption here is that the finer filter will be working harder, which is true initially. However, after the cleanup period, the removal of the previous high levels of particulate will reduce the wear rate, resulting in less work for the finer filter. Additionally, better quality system filters with a finer rating typically use synthetic fibres, which often have a higher dirt holding capacity than cheaper elements of a coarser rating.

Indeed, though, there is no point in fitting better filtration without first taking steps to prevent the ingress of solids, such as uprating the breather, seals, and gaskets, and improving the transfer and storage practices. Remember, it is easier to keep dirt out of the oil than to remove it from the oil.

“Surely fitting finer filters will impact the pressure delivery to the machine.”

Obviously, assessing the pressure drop across the filter is essential. Indeed, it may be necessary to increase the filter housing dimensions or to put two filters in parallel to maintain the correct differential pressure. However, as mentioned above, better quality system filter elements with synthetic fibres smaller than those in cheaper elements will have less restriction to the oil flow. Thus, the pressure drop is less affected.

Key Factors That Define When a Filter Is Too Fine

Target cleanliness levels to achieve the desired reliability.

This means we need to look at the following issues:

- Machine type – what clearances are we dealing with, and how susceptible is the machine to solid particle damage?

- Ambient conditions – how dusty is the environment, including not just from the process, but also geographically and with respect to the weather and winds.

- Lubricant type – particularly with respect to the additive package restrictions.

Machine Type Considerations

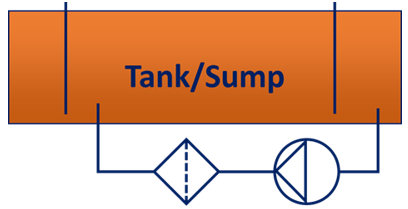

In order of cleanliness needs, gearboxes are the least concern since with their hardened surfaces and the typically higher viscosity oils, they are reasonably tolerant of particulate and therefore, while they do undoubtedly benefit from cleaner oil, the need for extreme fine filtration is unlikely and consequently, something like a ß10 > 1,000 is often sufficient.

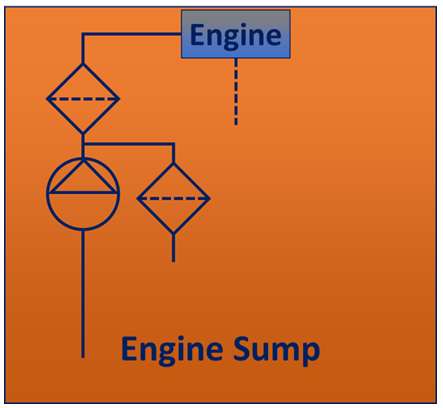

While engines will benefit from cleaner oils than gearboxes, there is the added pressure of the soot loading. Although correctly dispersed, soot is unlikely to trouble the filter because it is well under 1µm in size. However, experience has shown that high levels, especially with dispersancy package failure, can lead to premature filter failure.

In these scenarios, ß15 > 1,000 is potentially the lower limit, although the quality of the fuel and lubricant may allow tighter levels. In addition, the use of by-pass filtration may allow for even finer protection, as it involves a small percentage of flow via the relief valve and diverts directly back to the sump without concern for the pressure drop.

Bearing oils need to be as clean as possible to avoid abrasive wear and fatigue, especially in rolling element bearings with oil films as thin as 1µm. However, in most cases, basic bearing oils are not highly complex in terms of additive formulations. Consequently, very fine filtration is possible with due care regarding the defoamant if it is used.

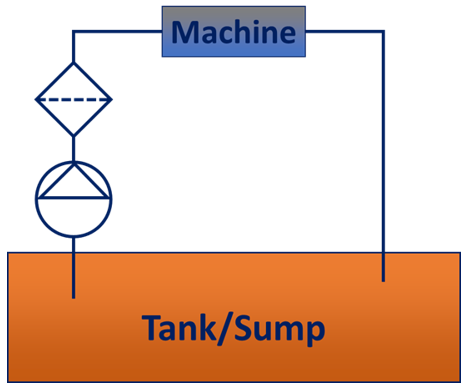

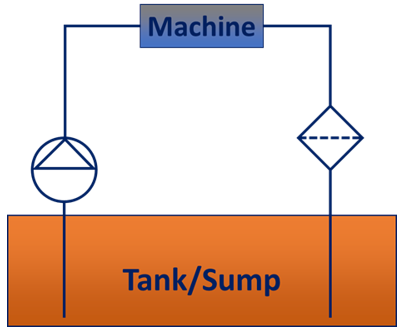

On turbines with plain bearings, then a ß7 > 1,000 is probably in order. However, in the case of turbine oil systems, the filtration is generally in the pressure line, so attention needs to be paid to the differential pressure. Therefore, it makes sense to consider off-line filtration, as it offers the benefit of a lower flow rate with minimal vibration, and the system does not need to be shut down for a filter change.

In these instances, the off-line skid unit may also incorporate water removal.

Hydraulics are probably the most complex in terms of cleanliness requirements, and it is in these fluid power systems that I often encounter enthusiastic engineers overindulging in filtration. Whilst hydraulics are usually the most susceptible thanks to their pumps and very fine clearances on the valves, the oils are also often formulated with defoamants, too.

Depending on the complexity, it may be a simple return line filter, but more complex ones will also have, or instead of, a pressure line filter. Generally, the limit on hydraulic oil filtration is around ß5 > 1,000.

Is Micron Size Alone Enough to Specify a Filter?

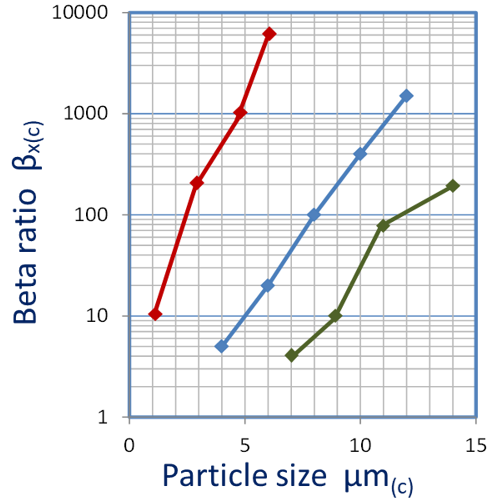

What irks me most is when people talk about filtration and discuss the micron rating without stating the Beta Ratio or Capture Efficiency. The observant amongst you will have noted that my guidance on the filter sizes stated above was with a Beta Ratio (ß) of 1,000 or a Capture Efficiency of 99.9%. This is three times better than a Capture Efficiency of 90% or a ß of 10.

Consequently, in my experience, a ß3 > 10 is no more harmful than a ß5 > 1,000. Just looking at the graphic below, we have three filters capable of stopping particles of 10µm, yet with widely different levels of performance. Therefore, it is important to be specific about the performance as well as the micron rating.

In summary, there is no absolute limit as there are a number of factors involved, not least the cost and ensuring that the return on investment is reached, which in itself will depend on the type and criticality of the system, so no, there is no easy answer to what the finest filter can use.