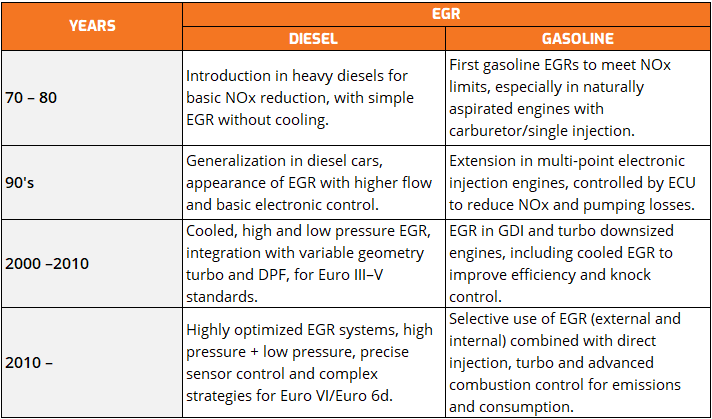

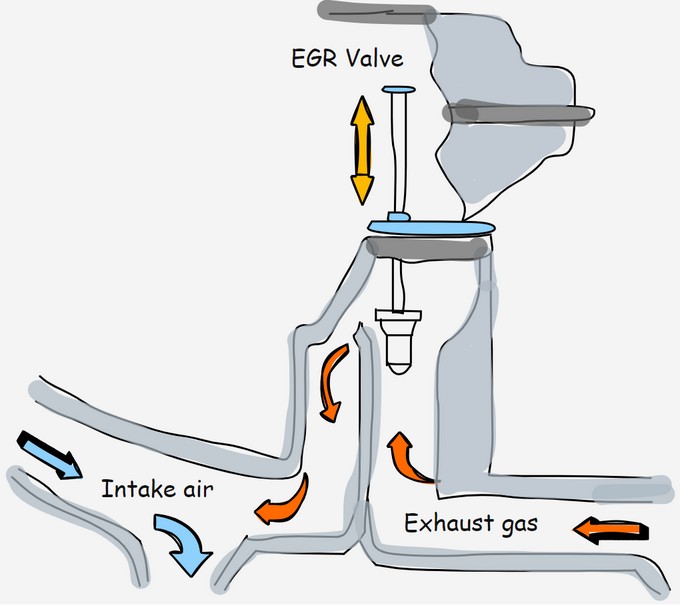

The EGR (Exhaust Gas Recirculation) system recirculates a fraction of the exhaust gases into the intake manifold to lower combustion temperature, reduce NOx emissions, and, in some cases, improve fuel consumption in both diesel and gasoline engines. This recirculation of hot gases introduces more soot, acids, and contaminants into the lubricant, accelerating its degradation and reducing engine life if not controlled with proper design, oil, and maintenance.

In diesel engines, the EGR valve diverts a portion of the exhaust gases before or after the turbocharger. It reintroduces them, often after cooling in an exchanger, into the intake to reduce effective oxygen and flame temperatures, thereby decreasing NOx formation.

The valve is governed by the ECU (Engine Control Unit) based on load, temperature, and rpm, opening primarily at partial loads and closing at cold idle or full load.

In gasoline, EGR can be hot or cooled. It is used to reduce part-load pumping losses and to lower NOx emissions. By recirculating inert gas, the valve can be opened wider at the same torque, reducing intake vacuum and improving efficiency. In GDI (Gasoline Direct Injection) and turbo engines, external or internal EGR (through valve overlap) is adopted to control combustion temperature and mitigate knock.

The latter refers to reducing the mixture’s tendency to detonate spontaneously before or just after the spark, a common problem in high-compression gasoline engines. Recirculating inert gases lowers the combustion temperature and slows the reaction rate, reducing the likelihood of knocking and allowing greater advance or load without damaging the engine.

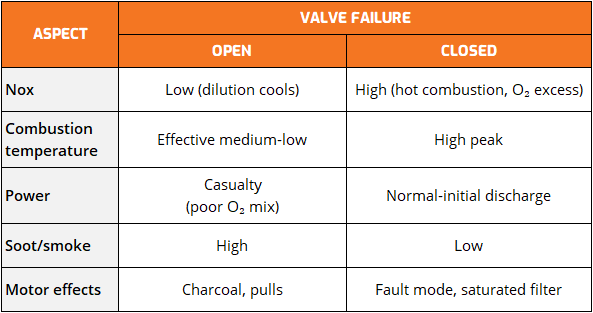

Typical EGR Failure Modes

No precise statistics indicate exact percentages of EGR valve failure modes. However, there are two failure modes that, depending on the engine type (diesel or gasoline) and the OEM, account for a high percentage of total failures. (1)

Open seized EGR valve ~ 65%

Excess recirculated gases, loss of power, smoke, possible increase of soot in the manifold and in the combustion chambers of the engine cylinders.

When the EGR valve is seized open, it recirculates excess exhaust gases (with soot and contaminants) into these chambers, diluting the fresh mixture too much, reducing power, and causing incomplete combustion that generates more soot accumulated on the walls of the chambers, pistons, valves, and intake manifold.

Excess soot in combustion chambers tends to raise temperatures, increase wear, and complicate gas flow in subsequent cycles, aggravating failures such as compression loss or excessive emissions.

In open-valve failure, the vicious cycle of soot obstructing the intake reduces airflow, forcing more fuel to compensate, increasing consumption and emissions. In contrast, NOx is reduced by excessive dilution. In diesel engines, it triggers frequent DPF regeneration due to low soot levels.

DPF regeneration is the automatic or manual cleaning process of the Diesel Particle Filter, which burns the soot accumulated in its ceramic channels to prevent clogging and keep emissions low, converting carbon particles into CO₂ and ash at temperatures of 500-600°C.

Closed seized EGR valve ~ 15%

High NOx, possible detonation, higher temperatures, and risk of thermal damage to metal components.

In a closed-valve failure, the ECU detects high NOx and enters safety mode (reduces power, limits rpm), accelerates piston thermal wear, and saturates the DPF due to insufficient dilution. In this failure mode, lubricating life degrades dramatically, reducing TBN at an accelerated rate.

In some post-2021 diesel engines, or Boxer-type engines with high-pressure EGR, a mixture of soot and light-fraction oil vapors from the combustion chamber forms dense sludge in the manifold, valve, and cooler, thereby aggravating EGR-system failures.

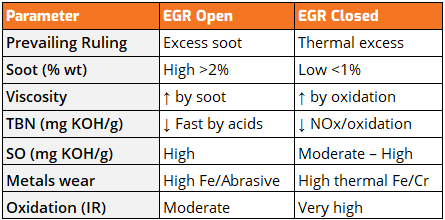

EGR failure identification opened by oil analysis

The failure mode of EGR valve seized open, excess recirculation introduces high volume of soot (carbon particles) and acidic contaminants (SOx, NOx dissolved) to the crankcase via blow-by, drastically raising the soot content (>2-5% wt), increasing viscosity and TAN (total acid number), and lowering TBN (total basic number) in an accelerated manner. This indicates incomplete combustion and dirt in intake – combustion chambers; oil detergents-dispersants become saturated, forming sludge and accelerating abrasive wear (Fe, Al, Pb high in iron, aluminum).

Closed EGR failure identification by oil analysis

In the closed-seized EGR valve failure mode, combustion is hotter. It generates greater oxidation/nitration of the oil, reflected in a high oxidation index (IR spectrum >30 Abs/cm), an increase in viscosity is evidenced by polymerization, and TBN is depleted by neutralization of the excessive load of NOx acids.

On the other hand, rising temperatures cause thermal wear due to thermal expansion. Increasing wear is measured by metal loss (chromium and iron from bearings/pistons). A low soot concentration (<2%) may be observed, possibly due to ECU injection adjustments that increase fuel dilution. In some cases, this dilution can cause the absence of soot despite high temperatures.

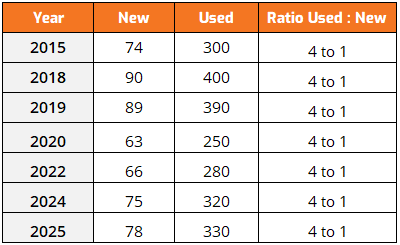

Global market for the sale of used and new cars

There is no accurate global data for annual sales of new and used cars worldwide. On the other hand, used markets vary significantly by region and country, and there is no unified source like OICA for used. But the data shows a worldwide trend where the sales of used cars exceed new cars by at least 3:1, according to the estimated data:

According to the data, it is very likely that, at some point, you will have to buy a used car; specifically, there is an 80% chance (equivalent probability) that you will do so.

At the same time, you’ve likely never done an oil analysis on your car. But if you’ve paid some attention to this article, chances are you’ve understood the value of a simple oil analysis—an analysis with a cost of nearly $30.

Over the years, I have helped several friends choose a second-hand car. Where the exterior can be very presentable, clean and very well maintained; But inside, where many times not even today’s computers can identify the problem unless it is very advanced states, a simple analysis of the oil in service can be the difference between buying a problem or making sure that the car’s engine – the heart of the machine – is working properly.