Varnish remains one of the main causes of premature failure in lubricants in service in turbines and compressors, and with a highly harmful effect on the mechanical components of the system.

It is estimated that the failure of a gas turbine caused by the presence of varnish has an estimated average cost of US$760 per hour, which includes the costs for unscheduled shutdown, the removal of the varnish present, and the replacement of at least 10% of the oil in service.

Varnish can quietly drain hundreds of thousands of dollars before a single visible failure occurs.

Although varnish is not a new problem, the increasing number of plants and machinery affected by it makes it clear that, on the one hand, analyzing oil in service is becoming increasingly necessary. On the other hand, laboratory analytical methods must be accurate to identify this problem in time.

Why Standard Varnish Tests Often Miss the Problem

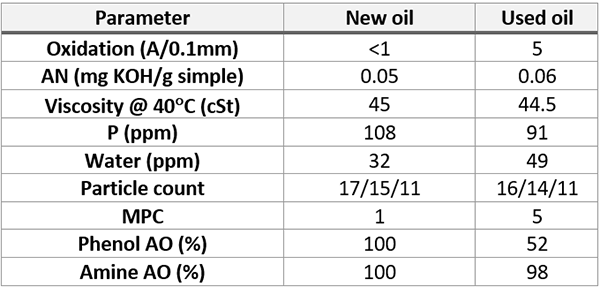

At the commercial level, the methods for determining the presence of varnish have been standardized and it is very common for lubricant analysis labs to offer a package that usually includes at least the following test: determination of suspended solid particles ASTM D7647 (reported with ISO 4406), FTIR ASTM E2412, acid number ASTM D664/974, ASTM D445 viscosity determination, ASTM D6304 water determination, ASTM D5185 element determination, ASTM D6810 organic additives determination, and ASTM D7843 patch colorimetry membrane MPC.

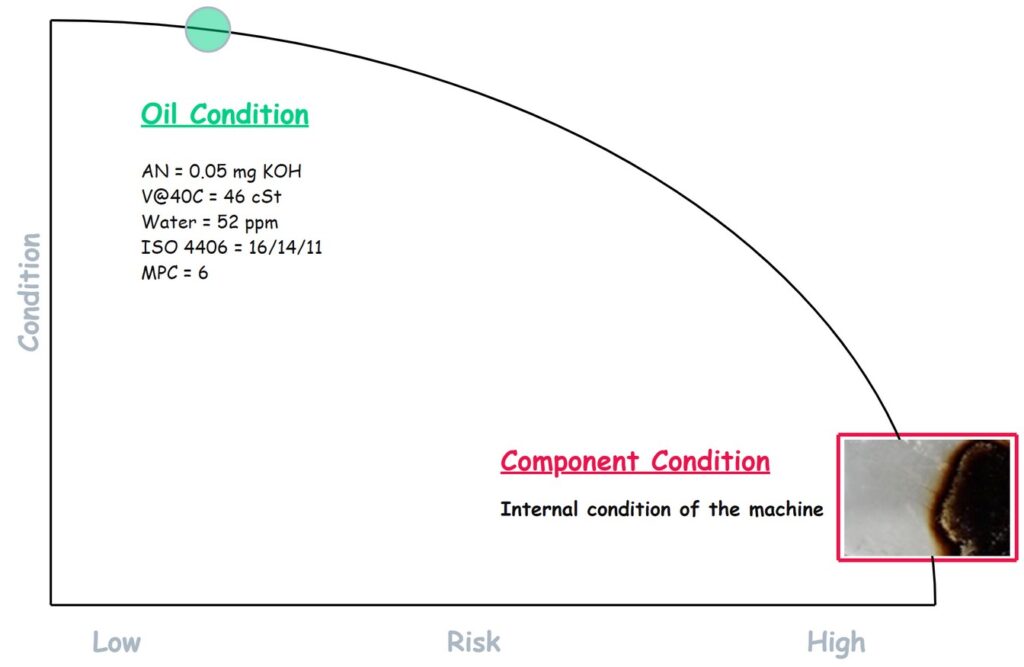

In many cases, all these values may be within an apparent normality; however, the internal components of the machine can show a completely different reality that becomes evident when the temperature of the oil in service shows an erratic and increasing trend. On the other hand, during general maintenance, the machine reveals an excessive amount of material adhered to the metal surface, which is varnish.

How is it possible that the oil shows no signs of degradation or physicochemical changes, at least at the surface level, while internally the components of the machine show clear signs of those degradation by-products called varnishes?

Are current laboratory analytical methods not well defined and have standardization undergone accepted by both end users and machinery manufacturers?

The above graph clearly shows the reality of many machines that, under the magnifying glass of standardized analysis for the determination of varnishes, do not show signs of the presence of these by-products. At the same time, the internal components tend to fail for this reason.

Anti-Varnish Products Market Trend

Since 2000, at least 16 different types of fluids have been developed and put on the market, specifically designed to reduce or eliminate the effect of varnish in gas turbines and compressors, depending on the type of definitions and technical terms. This figure includes both lubricants with advanced formulations and specialized cleaning products.

Examples of these fluids include:

- Group II base oils with improved additives for solubility and varnish control.

- Varnish remediation systems that remove varnish precursors in the oil.

- Turbine oils with proprietary additives.

- Polyglycol lubricants, which do not form varnish and remove the existing varnish in compressors.

- Specific cleaning fluids that keep degradation byproducts and varnish precursors in suspension.

- Synthetic and mineral oils with anti-varnish

- Lubricants with state-of-the-art additives.

- Cleaning products for varnish flushing in lubrication systems.

In many cases, the development of these fluids has been driven by the increased operational demands of machinery, higher oil temperatures, and the need to extend both lubricant and equipment life.

While in others it is mainly due to changes in the formulation of base oils, especially the shift from Group I oils to Group II oils with lower solvency, this facilitates the formation of varnish because these oils tend to keep the polar substances less dissolved as degradation by-products and responsible for the varnish, causing it to fall into the components.

On the other hand, there are factors specific to the end user:

- There is Greater Industrial Awareness: industry is increasingly recognizing the detrimental effect of varnish and the need for proactive (not just corrective) strategies for its prevention and removal.

- Increase in Varnish Reported Failures: Leading lubricant analysis laboratories in the industrial market report an increase in the presence and recognition of varnish-associated problems of around 600% over the past decade, especially in sectors such as power generation and oil & gas.

- Demand for higher Availability and Reliability: The need to maintain operational efficiency in critical turbomachinery motivates operators to invest in advanced lubrication and varnish management solutions.

Case Study: A Typical Situation

The most typical situation is one in which the client performs an analysis with a relatively adequate frequency, quarterly, and the results of the standard analysis are reported as normal:

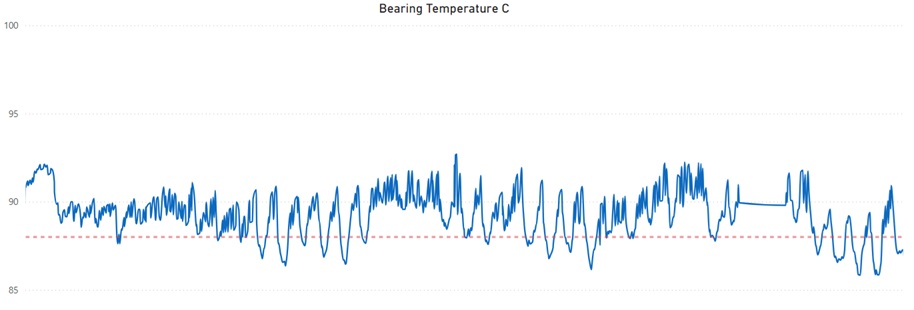

However, after a few months, the customer observes an abnormal trend in the temperature of the oil, with clear signs of erratic behavior and a potential internal problem.

On the one hand, the temperature has increased by 7°Celsius compared to usual. On the other hand, a marked trend of sawteeth shows an anomaly that coincides with the presence of polar elements adhered to the surface of the components.

When the scheduled shutdown arrives, the presence of varnishes in the system is evident; the seals, the cooling system, and parts of the tank show this presence. However, if the system shows an imminent presence of this type of by-product, what is the reason why there are no traces of these in the lubricant, and on the other hand, what improvements can be made at the laboratory level to identify this presence in advance?

Can traditional laboratory tests determine the presence of dissolved varnish?

Laboratory Analytical Improvements

The traditional or standardized methods of commercial laboratories for the determination of varnishes in lubricated systems do not cover the entire spectrum; they aim rather at those varnishes that precipitate and not those that tend to remain in solution.

In many cases, this condition of degradation byproducts is precisely due to the application of at least one of these 16 different types of fluids developed in the last 25 years; In any case, the system maintains the presence of by-products that at some point will tend to adhere to the metal parts of the system, causing in many cases production losses and unscheduled stoppages.

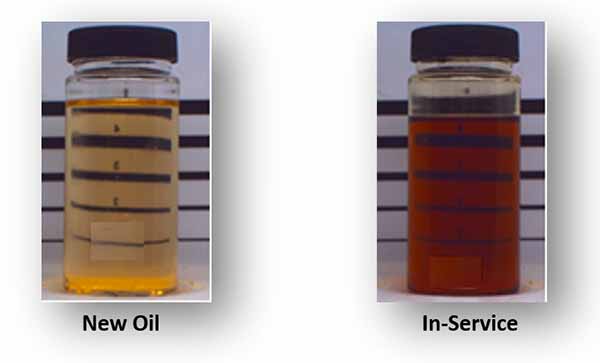

Let’s first analyze color. On the left, the oil before service, and on the right, after two thousand hours in service.

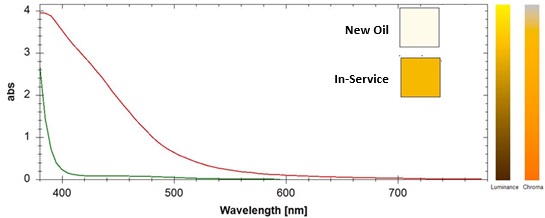

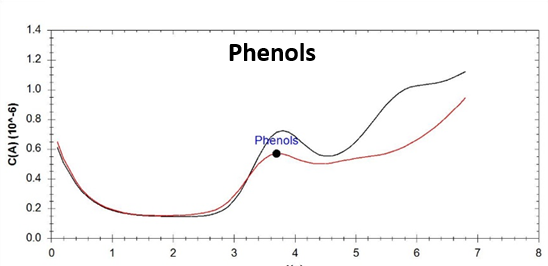

Let’s look at this same color change under the magnifying glass of the absorbance spectrum:

Oil sample visible spectra: New (green), in-service (red)

The color is an indicator of a chemical change in the oil that physically affects the molecular structure. In this case, the change is both measurable and quantifiable, as we have a starting point and a point where the oil is after a few hours of being in service.

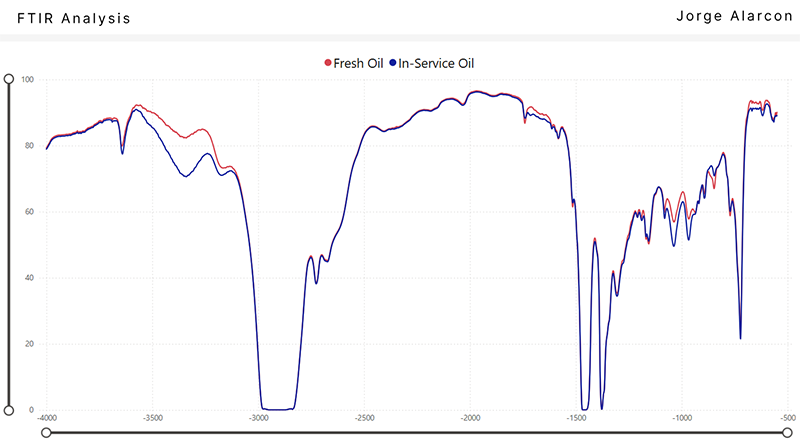

New compounds formed. It is evident that the change in color indicates a change in the chemistry of the lubricant, which is not detectable by traditional means, but is detected under an advanced FTIR analysis, the same that is used with little judgment to measure the oxidation of an oil of this type.

That color is due to the formation of intermediate compounds such as alcohol, aldehydes, and others. On the other hand, the loss of anti-foam characteristics of the lubricant is evident.

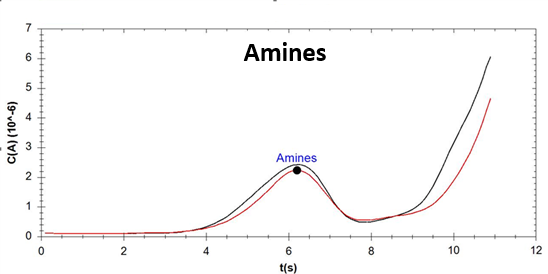

Concentration of Organic Additives. The most accurate technique for the determination of this type of additives is by Differential Pulse Voltametry (DPV). This technique enables the clear determination of low concentrations or incipient changes that other techniques cannot detect.

The Rosetta Stone. Egyptian culture could not have been discovered had it not been for Champollion being able to decipher the Rosetta Stone. In a simile, temperature plays a key role in this entire analysis and is the missing piece that, in many cases, can help to understand and determine the present state and future condition of an oil that has dissolved degradation byproducts, varnish precursors.

We thus have a combination of three laboratory analyses that determine the condition of the oil at a specific time and the temperature, which tells a much longer story and, once modeled, serves to determine the future condition of the oil.

Achieving the modelling of temperature data, without having known any failure, can be a titanic task. However, applying mathematical models such as Time Series Analysis or Neural Networks allows us to predict a future state based on the condition of the oil in service. The next step is to create connectivity between the lab and the machine, using gateways such as IoT platforms or directly from the Scada system.

When labs connect directly with machines, oil analysis shifts from reactive testing to true failure prediction.

Integration allows for determining not only those potential lubricant failures but also serves as a trigger that indicates the best time to take a sample.

For many industrial lubricant analysis laboratories, integrating operational data has become a reality that enables the prediction of potential lubricant failures, as illustrated in this case.

The Industry 4.0 trend has knocked on many doors, will it be the case that commercial laboratories open a window and breathe this air?

Will end users be able to allow access to their data to improve the service?

As an end user of turbines or compressors, would you be willing to take the next step and start a new type of analysis that helps you identify problems early?