It’s very much a lubrication issue. To prevent two metal surfaces from welding due to excess friction, keep them apart when expected to interact. A suitable film of lubricating oil accomplishes that.

Some 50 years ago, MIT Mechanical Engineering Professor Emeritus Ernest Rabinowicz was experimenting on the tribological effects of metal-to-metal surface interaction. In his research, Dr. Rabionwicz discovered that 70% of bearings lost their usefulness due to (avoidable) surface degradation, 20% due to corrosion, and a whopping 50% due to mechanical wear.

In calculating the situation, Rabinowicz determined that 6% of the U.S. GDP (Gross Domestic Product) was lost every year through mechanical wear. In today’s terms, that equates to trillions of dollars lost to avoidable wear. We now refer to this equation/finding as “The Rabinowicz Law.”

Simply put, surface degradation can be directly and indirectly attributed to ineffective lubrication practices.

These include under- and over-application of lubricant, use of mixed lubricants, incorrect lubricant choice (viscosity and additive package), particle and moisture contamination, and neglect.

Adopting a 5R Lubrication Approach by applying the Right lubricant, in the right place, in the Right amount, at the right time, with the Right level of cleanliness, surface degradation can be minimized to acceptable and often negligible levels.

Once established, the level of lubrication protection is dependent on the lubricant film, the thickness of which affects and controls the degree of interacting surface degradation and resulting wear. These varying thickness states are called lubricant film regimes.

Lubricant Film Regimes

There are five lubricant film regimes. Each describes a different relationship between two interacting surfaces as they slide over one another.

HDL—Hydrodynamic Lubrication is often described as “Full Film” lubrication, in which the moving surfaces are completely separated by the lubricant.

Viewing bearing surfaces under a microscope reveals that even finely machined surfaces are anything but flat. They’re more likely to resemble a series of craggy, rubbed-down peaks and valleys.

A lubricant must first fill those cavities to separate and ensure optimal interaction between two moving metal surfaces. In sliding friction bearings, HDL is the most desirable lubrication state. It’s often referred to as thick-film lubrication, wherein any friction is entirely due to the fluid friction between the viscous planes shearing in the lubricant.

EHDL—Elastohydrodynamic Lubrication is unique to rolling-friction surfaces seen in ball—and roller-style bearings and in combination with sliding- and rolling-friction circumstances found in the mating of gear teeth as they pass over one another.

When a ball is rolling in a race and comes under full load, the mating surfaces will momentarily deform, trapping the lubricant in the deformed area known as the Hertzian contact area. Under deformation pressure, lubricant viscosity rapidly rises, and the lubricant changes state from a liquid to a solid, thus providing complete protection to the rolling surfaces.

The lubricant returns to its original viscosity as the ball moves out of the load zone. Because rolling-surface contact is in a line and not over an entire surface area, far less lubricant is required to achieve full-film lubrication. Viewing a vehicle’s tire in motion can easily demonstrate this action.

A properly inflated tire always appears round except for the deformed or flattened portion, taking the load and providing traction with the ground. As the tire rotates, it elastically comes back to its rounded form.

MF – Mixed Film Lubrication is classified as an Intermediate lubrication regime when lubricant is present between two sliding surfaces but not enough to fully separate the surface, allowing intermittent contact between the highest points of the surface peaks. This is known as an “unstable” regime.

Extended time spent in this regime will result in the surface high points shearing off and, in turn, create additional cutting wear to the bearing surface due to asperities rubbing both surfaces. MF conditions are generally caused by insufficient lubricant, heavy loads at rest, or using a lubricant with too low viscosity.

In the 1800s, steam engines were designed with large-diameter Babbit (very soft material) crankshaft bearings. These bearings were lubricated with two different manual-oil-lubrication-delivery systems used in sequence.

The first was a manual pressure pump used to hand-pump oil into the bearing cavity and hydraulically float the bearing before startup. Once running with the shaft at a steady 70- to 100-rpm working speed, lubrication delivery was switched to a gravity-feed oiler that ensured continuous flow into the bearing to achieve full-film lubrication.

This two-part process moved a bearing’s lubrication state from HSL to HDL while minimizing/eliminating the problematic effects of MF and BL (see below) lubrication states.

BL – Boundary Layer Lubrication, or thin-film lubrication, is the least desirable regime offering the least frictional protection. Although minimal lubricant is present, the sliding surfaces are in full contact with one another at rest. With heavy loads and slow-moving machinery, a BL to MF regime may be the best condition achievable. This situation, though, requires a lubricant with EP (Extreme Pressure) and AW (Anti Wear) additives to offset the extreme bearing-surface working condition.

If insufficient lubricant or an incorrect viscosity is used, a normally loaded bearing can stay in a boundary-layer state when in full motion. In that case, the surfaces will interfere and cause rapid wear.

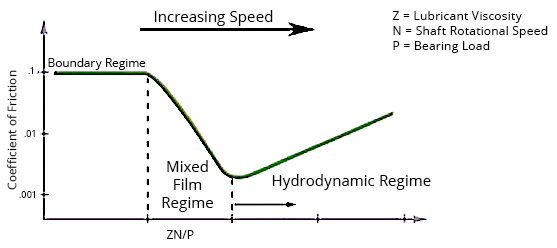

In 1902, Professor Richard Stribeck graphically described the coefficient of friction changes for bearings under different lubrication regimes. His work resulted in what we know as the Stribeck Curve (see figure). The Stribeck Curve demonstrates that hydrodynamic film regimes of the correct viscosity and Lambda thickness lead to the lowest coefficient of friction and least wear.

The Stribeck Curve describes the coefficient of friction changes for bearings experiencing different lubrication regimes.

A typical example of Stribeck’s findings is found in normally loaded sliding friction bearings, such as those in a shaft and sleeve bearing setup. At rest, the bearing surfaces will begin in a boundary-layer or mixed-film state before startup or shutdown.

As the shaft ramps up speed, it will start to centrifugally center and move through a mixed film regime to a full film HDL regime at operating speed. Load, speed, and lubricant viscosity changes can also affect the regime state.

Full-film lubrication has a typical thickness between 1 and 5 microns. To put that into perspective, consider that bacteria are 2 microns in size; a red blood cell is 8 microns; a human hair is 75 microns or 0.003 of an inch. In contrast, silt or dirt comes in at around 5 microns (possibly larger), which could easily create wear surface damage if allowed into the bearing surface area.

Humans only begin to see objects at 40 microns in size. Therefore, we must be diligent in understanding and ensuring that the 5 Rights of Lubrication are always followed. Doing so will ensure a bearing operates in its designed lubrication regime, avoids unnecessary wear, and lives a long life. In the end, a bearing’s fate is always in the hands of the maintenance department.

First published in The RAM Review