When I go into industrial plants and tell the Lubrication Team, aka, oilers and greasers, that they are Tribologists, I usually get a look of confusion on how they would fit in. When you first think of Tribology, your thoughts may immediately go to all the great PhD scientists who have excelled in this field, starting from the coining of the term by Dr. Peter Jost, the Father of Tribology.

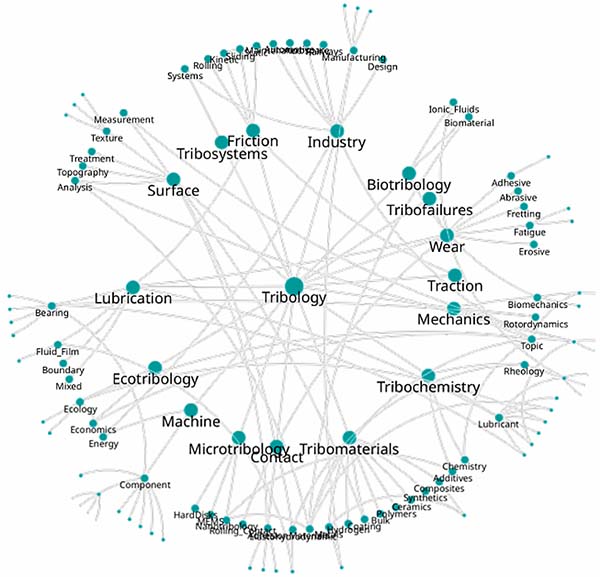

In a review by Enrico Cuilli of the University of Pia titled “Vastness of Tribology Research Fields and Their Contribution to Sustainable Development,” you see a graph that outlines all the areas that spin off from the original explanation of Tribology as shown in Figure1.

At its core is the definition of Tribology as the science and engineering of interacting surfaces in relative motion, with a focus on friction, wear, and lubrication. It applies to everything from R&D to mechanical systems such as bearings and gears.

Figure 1: Are you a Tribologist? Photo Reference: Vastness of Tribology Research Fields and Their Contributions to Sustainable Development Dr Enrico Ciulli, University of Pisa

Industrial Tribology brings the maintenance and reliability teams into the Tribology family, putting to work “all the applications of tribology to the industrial products, manufacturing, and maintenance. CONGRATS, YOU ARE A TRIBOLOGIST!”

Looking at the areas that deliver the best R&D in Tribology and how they fit the production floor, there are three main areas of focus: lubrication, friction, and Tribochemistry.

Lubrication includes bearing selection, proper fluid film, and Machine components, requiring the gearbox, electric motor, or hydraulic system that best fits the application.

Friction is determined by the type of rolling, sliding, or static contact, the industry, what you are manufacturing or designing, and the Tribofailures, to determine the root cause of failure.

Lastly, as a tribochemistry field lubrication specialist, you must evaluate many products to determine the best lubricant for your application.

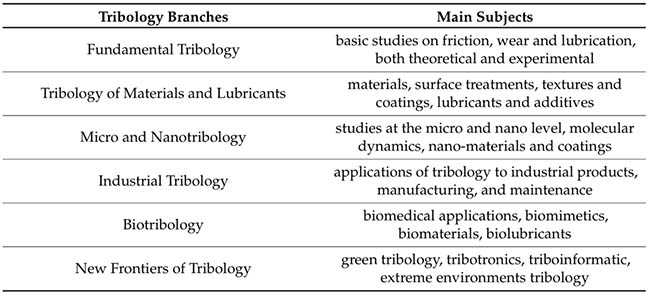

The table below (Figure 2) provides additional explanation of the various branches of tribology and the main subjects they cover.

Figure 2: Tribology branches and their main subjects. Reference: Vastness of Tribology Research Fields and Their Contributions to Sustainable Development Dr Enrico Ciulli, University of Pisa

In Industrial Manufacturing Tribology, it also includes metal forming, maintenance, maintenance monitoring (KPI’s), and condition monitoring of lubricant health with oil analysis. The lab tribologist reviewing oil reports to determine additive strength, wear metal and contamination concentrations and sources, and oxidation levels can advise users on getting the full value and life from their lubricant.

This will also assist your team in managing time to extend drain intervals, reduce labor costs, and allocate time to other lubrication/reliability projects. Tribology affects everything and everyone.

The goal for Tribologists on the research side is to understand, on the nano-level, the three main components of friction (lower), wear (eliminate), and lubrication (best formulations) to improve energy efficiency, life span of the asset, and increase performance. This will not only make your company profitable (the cake) but also lower your carbon footprint (the icing on the cake).

If maintenance teams embrace this concept and communicate to management that they are one of the plant’s best assets, they could receive buy-in and support to expand and grow their proactive maintenance program with new equipment and training. The key to this is making sure you are documenting all increases in your production KPI’s and decreases in downtime to keep the management philosophy of “what have you done for me lately” concept addressed.

As we welcome you, the heroes of maintenance and reliability, please know that, as an Industrial Tribologist, you must have a desire to learn and grow every day in this field, and that you are a very important part of the company. You not only make them profitable but also lead the way in energy efficiency for every electric motor, gearbox, and hydraulic unit, and you create the “icing on the cake” as good stewards of the environment. To learn more about Tribology connect or join the Society of Tribologists and Lubrication Engineers.

Reference:

Ciulli, E. Vastness of Tribology Research Fields and Their Contribution to Sustainable Development. Lubricants 2024, 12, 33. https://doi.org/10.3390/ lubricants12020033