In the high-stakes arena of power generation, turbine oil life has always dictated the tempo of reliability. A century of operating experience taught plant engineers one brutal truth: once an oil’s antioxidant package collapses, varnish doesn’t politely knock—it kicks the door in. The remedy was equally blunt. Drain. Flush. Refill. Get the unit back online and hope the schedule and budget survive the ordeal.

That reactive ritual hid monumental costs. A forced turbine outage can swallow $250,000 to $1,000,000 per day in lost generation revenue, while a single high‑temperature flush consumes significant new oil, dozens of labor‑hours, and tens of thousands of dollars. Worse, none of it addresses the root cause; the fresh charge begins oxidizing the moment the turbine starts spinning.

A New Paradigm for Turbine Oil Management

In‑situ antioxidant replenishment rewrites that playbook. By selectively re‑injecting antioxidants—precisely matched to the base stock’s solvency—the oil’s oxidative resistance is restored without interrupting production. Think of it as administering a targeted vitamin boost rather than performing an organ transplant.

Key performance indicators such as RULER® antioxidants (D6971) and Rotating Pressure Vessel Oxidation Test (D2272) values rebound while varnish potential plummets—often within a single maintenance shift.

Replenishment turns turbine oil from a consumable into a long-life performance asset—without interrupting production.

The implications extend far beyond chemistry. Extending oil life from a typical 7–10 years to 20 years or more eliminates at least two full drain‑and‑flush cycles over a turbine’s design life, slashing cradle‑to‑grave carbon intensity by 100 t CO₂e per machine. Just as importantly, replenishment keeps the unit’s reliability curve flat, removing the “bathtub” spike in failure probability that coincides with oil change‑outs. In short, it turns lubrication from a consumable into an asset, aligning maintenance strategy with the realities of decarbonization and relentless uptime expectations.

Ensuring Reliable Outcomes With Antioxidant Replenishment

Traditionally, when turbine oils experienced antioxidant depletion, the default response was to completely replace the oil, typically involving a full system flush. Yet this costly and disruptive routine isn’t always necessary. In fact, even when the antioxidant stability drops to around 25%, the underlying base oil often remains in good condition. Addressing the issue early by replenishing these critical antioxidants can prevent lasting damage. Achieving this, however, demands specialized expertise in formulation chemistry and thorough preliminary testing to ensure the right approach.

Even at 25% antioxidant remaining, base oils are often still viable—replenishment prevents costly, unnecessary oil changes.

Before applying antioxidant replenishment in actual turbine operations, it is essential to evaluate the long-term effectiveness of the antioxidant concentrate through laboratory testing. The Turbine Oil Performance Prediction (TOPP) test serves as an ideal evaluation method, offering precise insights into antioxidant performance and deposit tendencies under controlled conditions.

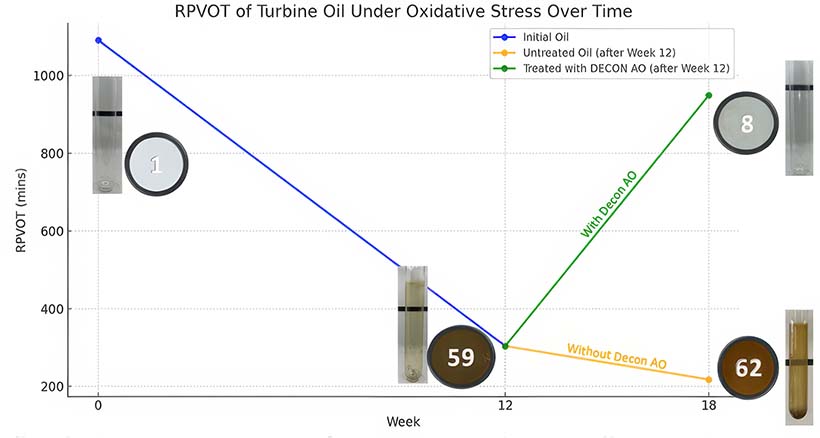

Consider an example from laboratory trial as shown in Fig. 1: a fresh turbine oil subjected to stress conditions for 12 weeks saw its Rotating Pressure Vessel Oxidation Test (RPVOT) value plummet from 1091 minutes to just 304 minutes, accompanied by a significant increase in Membrane Patch Colorimetry (MPC) from 1 to 59, clearly indicating oxidation damage and visible deposits.

Splitting this stressed sample and treating half with DECON AO resulted in performance improvements. After an additional six weeks under identical conditions, the untreated portion deteriorated further.

In contrast, the treated sample recovered, ultimately reaching an RPVOT of 949 minutes, exhibiting minimal varnish potential, and showing no glassware deposits. This clear demonstration underscores the practical effectiveness of antioxidant replenishment in maintaining oil integrity and extending its operational life.

Figure 1: The effects of adding DECON AO to a sample that has been stressed for 12-weeks in the TOPP test.

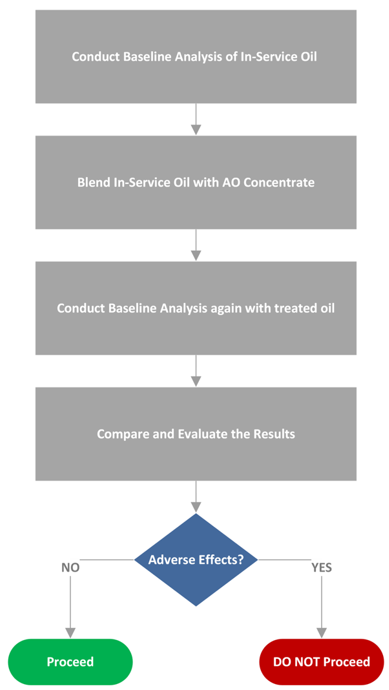

The laboratory experiment illustrates the effectiveness of Decon AO. Yet, transitioning this success from the controlled environment of the lab to the dynamic realities of field operations requires preparation and validation. To safely apply antioxidant replenishment in real-world conditions, the following process is suggested to mitigate risk:

- Begin with a baseline analysis, adhering to ASTM D4378 protocols. Oils that show severe degradation—particularly those with acid numbers greater than 0.4 mg KOH/g or significant water contamination—are usually disqualified.

- Carefully blend the in-service oil with the selected antioxidant additive concentrate, typically around a 3% concentration. This mixture should then be heated to 65 °C and maintained at this temperature for a 24 hours.

- Conduct baseline testing once more on the treated oil blend.

- Evaluate the results by:

- Confirming that no negative changes occur regarding performance indicators, such as Membrane Patch Colorimetry (MPC), rust inhibition, demulsibility, air release, and foam characteristics.

- Verifying significant improvements in the oil’s oxidative stability, measured through RPVOT and RULER results.

- If testing demonstrates no adverse effects and shows substantial enhancement of oxidative stability, the in-service oil is deemed suitable for antioxidant replenishment. If these criteria aren’t met, antioxidant replenishment should not proceed.

This process is summarized in Figure 2.

Figure 2: Process to Qualify an In-Service Oil for Additive Replenishment

A Quiet Revolution Accelerates

The momentum behind antioxidant replenishment is building quickly. Back in 1954, as Elvis Presley recorded his groundbreaking hit, “Rock Around the Clock,” which symbolized the revolutionary birth of rock ‘n’ roll, another revolution was quietly underway in the oil industry.

Norris and White, innovators at Socony Vacuum (now ExxonMobil), introduced a groundbreaking concept—small, precise additions of additives that could stabilize turbine oils without the costly disruption of full oil replacements. For decades, this innovative yet understated approach quietly supported power plants, often without much fanfare, as oil manufacturers discreetly offered antioxidant top-ups to help resolve customer challenges.

Today, however, what began as a subtle shift is rapidly gaining industry-wide recognition. Recent years have seen a surge of formal endorsements, technological advancements, and strategic implementations by industry leaders, highlighting a decisive shift towards antioxidant replenishment as an accepted best practice. This evolution underscores the industry’s increasing alignment with sustainability, cost efficiency, and proactive maintenance principles.

Much like Rock ‘n’ Roll transformed popular culture, antioxidant replenishment is steadily transforming turbine oil management, redefining the way power plants approach reliability, sustainability, and operational efficiency.

From Theory to Reality: The Proven Path of Antioxidant Replenishment

The conventional approach to managing turbine oil degradation—drain, flush, and refill—has historically been both costly and environmentally taxing. However, in-situ antioxidant replenishment technology is rapidly reshaping this narrative.

What was once theory is now proven: antioxidant replenishment extends oil life while cutting cost, downtime, and emissions.

By selectively restoring antioxidants matched precisely to the oil’s chemistry, operators effectively halt oxidation without disrupting turbine operation. This innovative approach not only restores oxidative resistance and drastically reduces varnish potential but also extends oil life, lowering lifecycle costs and significantly decreasing carbon emissions.

Industry adoption of antioxidant replenishment is accelerating, evidenced by multiple endorsements, technical standards, and real-world applications demonstrating tangible benefits. What was once a theoretical possibility is now a proven industrial practice, heralding a future where proactive lubricant management enhances reliability, environmental stewardship, and operational efficiency.

References

- H. D. Norris and R. V. White, “Antirust Agent,” U.S. Patent 2 490 744, 13 Dec 1949.

- H. D. Norris and R. V. White, “Turbine-Oil Antioxidants,” U.S. Patent 2 697 074, 14 Dec 1954.

- Mitsubishi Heavy Industries, “Antioxidant Refill System and Method,” JP 2023-160717 A, 22 Jun 2023.

- C. Bequette et al., “Integrated System and Method for Automatic Rejuvenation of Turbine Oil,” U.S. Patent 11 639 771 B2, 2 May 2023.

- ASTM International, ASTM D7155-20 – Standard Practice for Evaluating Compatibility of Mixtures of Turbine Oils, West Conshohocken, PA, 2020.

- G. Livingstone and J. Joy, “Antioxidant Replenishment Doubles Turbine-Oil Life: Mesquite Power Case Study,” OilDoc Conference Proceedings, Rosenheim, 2017.

- MHI Power Systems, “On-Site Oil Regeneration Through Adsorption and Antioxidant Replenishment,” MHI Technical Review, vol. 61, no. 2, pp. 30–35, 2024

- Vanderbilt Chemicals LLC, VANLUBE ® 407 as a Top-Treat Antioxidant for Turbine Oils (technical brochure), 2017.

- A. B. Lantos, “Assessing Oxidation Condition and Lubricant Refreshment in Turbine Oils,” Machinery Lubrication, Jul 2020.

- G. Livingstone, “The Journey to Fill-for-Life,” Machinery Lubrication (White Paper), 2020.

- E. Perez, “Extending Lubricant Life Through Antioxidants,” Turbomachinery International, vol. 55, no. 3, pp. 28–32, 2014.

- Thermal-Lube Inc., Additive Reconstruction of Oils (technical bulletin), 2021.