In my recent article, “Improve The Reliability of Hydraulic Systems for Just Pennies A Day,” I used the term “creep to failure.” It describes mechanical systems that continue to work, albeit inefficiently, for extended periods despite suffering from disrespect, abuse, and lack of maintenance.

The forgiving nature of these systems promotes apathy in production and maintenance department attitudes toward system/component failure prevention, efficiency optimization, and service-life management. That apathy, in turn, can lead to significant or catastrophic failures at the least opportune times.

“Creep to Failure” systems are recognizable by their purposeful, built-in “weak-link” design elements, i.e., common elements that rely on engineered sacrificial components.

Often integral to the functional design, these critical, multi-function, sacrificial components are primarily engineered to protect their respective systems from premature wear due to poor setup, calibration, operating conditions, and, sadly, downright abuse.

As such, these components are inexpensive compared to the system they protect. And they must be checked and replaced once they’ve reached the end of their wear region or point of exhaustion.

The hydraulic fluid and filtration elements are the sacrificial components in hydraulic systems. Mechanical systems also employ lubricants and filtration to protect the moving surfaces. But unlike hydraulic systems, they employ sacrificial drive chains, sprockets, belts, and pulleys to transmit power.

These components serve not only to connect and transmit power but also to protect the driver and driven components by taking up/absorbing misalignment, vibration, and power surges within the transmission system.

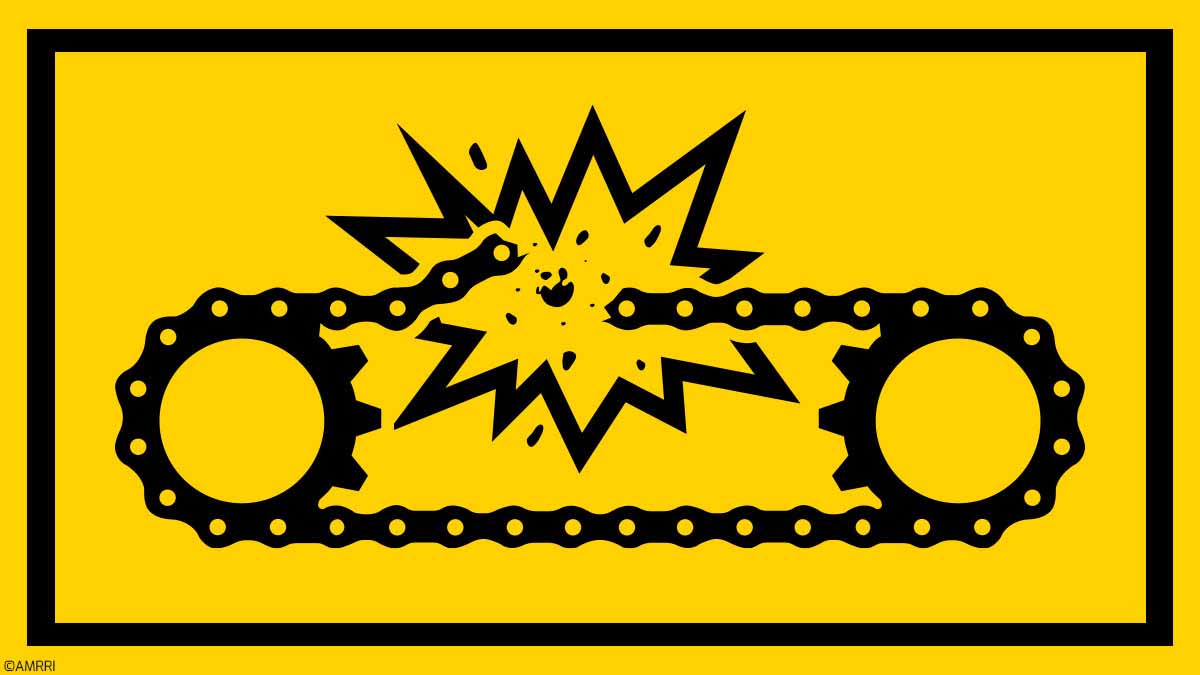

Chain And Sprockets

Chain and sprocket sets are unique in that they also rely on the sacrificial nature of lubricants to remain clean, friction-free, and long-lasting.

Chains and sprockets are excellent torque transmitters and are tolerant of both heat and high loads. Custom-sized with little difficulty, they can accommodate long shaft-center distances and configurations not easily achieved with belt-driven systems or direct-drive gearing.

However, if not lubricated or cleaned regularly, chains and sprockets will wear rapidly and can fail catastrophically, causing great physical damage at speed.

Under regular operation, the outer surface of a chain’s pins and bushings connecting its links will “rub” against one other and create friction. This friction causes pin surfaces to wear and lose their rigidity to the point of fatigue failure.

Although it is technically possible for the chain link to “grow” in length slightly, the phenomenon known as “chain stretch” is actually elongation caused by material-wear loss on the pins connecting the links.

When wear occurs, the chain roller creeps up the sprocket teeth as it rolls over them. This, in turn, causes tooth wear, creates system vibration, and allows the chain to “jump” the sprocket teeth. The situation can be catastrophic when a timing chain connects two or more sequenced-driven systems.

Chain looseness and vibration will dramatically affect the machine’s energy efficiency. If allowed to deteriorate further, the chain can be ejected off the sprocket entirely, snap or wrap around a moving shaft, and cause significant secondary damage and/or loss of machine function, commonly referred to as downtime.

Gauging when to change out chains and sprockets requires examination of both components. Chain manufacturers recommend replacing the chain once it has reached a 1.5% elongation of its original length.

This can usually be determined using a vernier caliper to measure and note the distance over a minimum of 10 chain links.

For example, if a new chain measures 10 inches over a 10-link span, the allowable elongation before replacement will be 10 x 0.015 = 0.15 inches, or 10.15″ over a 10-link distance. (FYI: Most chain manufacturers sell a simple chain-link Go/No-Go measuring device that can indicate the elongation change point.) The shape of their teeth determines sprocket wear.

While maintaining chains and sprockets isn’t complicated or expensive, these sacrificial components require commitment and respect. The following points reflect a set of minimum maintenance requirements:

- Lubricate! Lubricate! Lubricate! Use a chain lubricant with tackifiers and creep agents that won’t fling off during rotation and will allow the oil to creep into the pin portion of the chain. NEVER USE DIRTY OR USED OIL.

- Investigate using a simple reservoir and brush-applied lubricator to oil the chain automatically.

- Regularly clean the chain with a wire brush, a purpose-built chain brush, a degreaser, or a purpose-built chain-cleaner attachment.

- Be sure to protect your chain and sprocket systems from contamination. Water and dirt can lead to contamination, wear, and rust.

- Make a simple set of Go/No-Go slip gauges (or use a commercial gauge) to hold against the slack side of the chain and a fixed reference point to check for minimum tension. (See the manufacturer’s chain-tension-measurement requirements based on chain size and length.)

- If possible, always replace sprockets when you replace the chain.

- Modify your chain guard with a bottom hinge so the transmission system can be accessed in less than 30 seconds.

- Precision-laser-align your chain sprockets.

- Beware of counterfeits. Stick with quality, name-brand chain and sprockets.

V-Belts and Pulleys

A V-belt is a simple device designed to wrap around a set of correspondingly shaped sheave pulleys. It connects a motor-powered drive pulley to one or more driven pulleys and transmits power at a defined number of revolutions per minute (rpm).

The belt is designed to “wedge” into the V-shaped sheave pulley and transmits load through its elastomer to the tension member, which transfers power to the driven sheaves.

During that power transfer, the belt is subjected to fatigue, which can eventually cause belt tension members to fail. The good news is that when correctly installed and tensioned, belts can transmit up to 98% driven power with a life expectancy of over 15,000 hours.

Premature failures, especially those that occur within the first 1,000 hours of operation, can sometimes be attributable to poor belt quality. For the most part, however, most premature failures are caused by heat.

They are overwhelmingly maintenance-related or maintenance-induced—the similarity among all these failures is that they are preventable.

V-belts perform best at operating temperatures between 90 and 120 F. Based on the Arrhenius rule, for every 18 F-deg. increase in a belt’s operating temperature, its expected life can be reduced by half.

Manufacturers point to elevated belt temperature as the number-one cause of failure in these components. The following points illustrate the key preventable contributors that cause belt-temperature elevation:

Belt Slippage

As a loaded belt unwraps from the driven pulley sheave, it tends to creep or slip as it releases while slowing the pulley. This is normal operation. A correctly tensioned belt is designed to slip between 1% and 3%. Less means the belt is too tight; more means it’s too loose.

Both conditions will cause belt temperature to rise. Slippage, or correct belt tension, is easily checked using a strobe rpm tool to check the speed rpm difference between driver and driven pulleys.

Newly installed belts should be tensioned at startup, again after running full load for 30 minutes, and 24 hours later, after the belt has seated into the pulley. With a 1:1 ratio driver-driven system at a measured 1800-rpm driver-pulley speed, the driven pulley should run between 1,782 rpm and 1,746 rpm (1% to 3% slip) under ideal tension.

A quick belt-tension check can also be performed using an infra-red (IR) temperature gun or camera to ensure the belt runs at a preferred operating temperature similar to that tested after proper tensioning.

Misalignment

Poor alignment causes the belt’s tension members to flex sideward and vibrate, creating additional stress. When a misaligned belt enters the sheave groove, it “rubs” the sheave wall, creating friction and wear of the sheave sidewall and belt.

Combined, all of these will raise a belt’s operating temperature. Sheaves can be offset and angularly misaligned if set up incorrectly. Always perform a precision alignment of driver/driven systems using laser or reverse-dial method to ensure minimal heat generation, wear, and energy loss.

High Operating Loads

When a driven system requiring multiple belts operates with loose, non-matched, or missing belts, belt loading will surpass the belt-design factor and create heat.

Always change multiple belts out as a matched set (from the same manufacturing batch or lot number), and check sheave pulleys for wear and change, as required.

Other basic-maintenance tips include:

- Protect belts from heat, dirt, water, and oil contamination.

- Always use a sheave-groove-profile gauge to check sheave wear. This $10 device is placed in the groove and a flashlight is used to detect light bypass. If more than .030″ light bleed is detected, immediately change the worn pulley. (FYI: Worn sheave pulleys make it challenging to tension belts correctly.)

Keep In Mind

“Creep to Failure” systems will eventually wear out. Simple setup and regular condition checks, though, can go a long way toward maximizing their life cycles, ensuring their reliability and availability, and minimizing their maintenance needs—and all for pennies a day.