This article chronicles a reliability journey at a chemical manufacturer in the Southeastern United States.

Implementing a reliability-based maintenance program has tremendous business benefits – the kind of impact that executives get excited about. Before our plant started down the reliability path, we spent $39.1 million in maintenance. We had 200 maintenance craftspeople and, on average, 250 contractors on site.

Seven years later, we spent $17 million and had 173 maintenance craft people and six contractors. We achieved these outcomes just by making work go away. This was not just a single-plant implementation. We worked across four sites, and they all got to about the same place.

Each site was expected to develop its own business case for the reliability project. I had that responsibility for our site. Developing and presenting it taught me a valuable lesson. When you create a business case that exposes a huge opportunity for a positive impact, that message will only sometimes be received well.

I compared our spending as a percentage of replacement value versus best in class to define our maintenance cost reduction opportunity. I also did some extensive OEE calculations by looking at our best month of production in each one of the operating areas. My reasoning was that if you could do it for a month, you ought to be able to do it for a year.

I used that approach to define the business opportunity from increased production. The result was so significant that I decided to be more conservative and cut them in half. It still felt too optimistic, so I cut them in half again.

When I presented the result to the leadership team, they laughed me out of the room. They could not believe that they were mismanaging the resources of that site so badly. Just expect skeptics!

The site where I got laughed out achieved results that doubled the initial business case. We were tracking the cost of reliability events, those major reliability events that cost you a lot of production, and they were steadily declining over time.

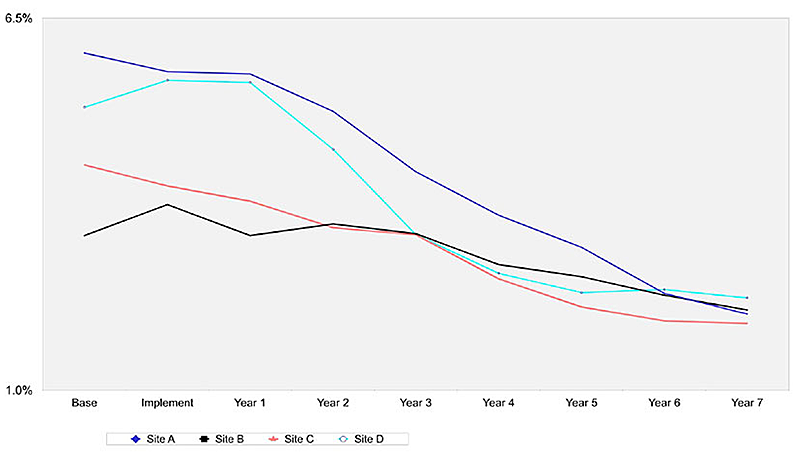

We received significant benefits in the procurement process by reducing costs and improved service levels. Below is a chart of the four sites that tracked maintenance spending as a percentage of replacement asset value. The benchmark value for this industry is somewhere around 2%. I was at the dark blue plant.

Because the sites were somewhat different in the products produced, we did not have a universal way to measure OEE. Still, each site had some improvements, and they were significant. I recall being at one of the sites when the plant manager put up a slide that showed the break-even volume over time – the volume needed to break even versus the actual production volume.

Break-even volume was going down because costs were being reduced, and production volumes were going up because they were improving capacity through reliability improvements. The spread between the two was increasing profitability. That resonated with me.

Plant Performance (Maintenance cost as a percentage of replacement asset value)

A reliability transformation delivers steady, continuous returns.

Active leadership support must be in place to drive culture change. One of the plants had active resistance from the plant manager, and he was replaced. Corporate leadership had the courage to take the hard road when necessary.

Change management is at least as important as the technical solution. It is a challenge within one site but a much more significant challenge across a group of sites. We had an executive sponsor that walked around with his finger in the air: one solution for all sites.

It was crucial as he was a big driver of that. I will never forget when executive sponsor came to the site I was at, he said, “I have implemented four maintenance systems in my career; this is going to be the last one. We are going to dismantle the past and hardwire the future.”

Having a high level of executive sponsorship is also critical for change management.

Read the rest of this series on the PCA Consulting website.